New 3D Printed Gripper Can Work Without Electronics

One area where it is expected to increasingly see the presence of 3D printing is in soft robotics. Indeed, the use of additive manufacturing allows for the design of complex and interesting robotics for a lower cost, making it attractive in the field. In the latest news, researchers from the University of California San Diego (UCSD) have announced that they have 3D printed a soft robotic gripper that not only was ready to use right off of the printer, but does not need any electronics to work

For those who may not be aware, soft robotics is a subfield of robotics wherein the robotics are made of flexible, or compliant, materials rather than rigid. Since becoming popularized in 2010, this field has become increasingly used especially for applications requiring biomimicry or in the medical field. The strength of these robots is that not only are they lightweight and portable, but they are also more adaptable than traditional robots. Additionally, they are ideal for times when robots need to interact safely with humans and delicate objects. Grippers for example are one area in which we have seen a sharp growth in its use. Now with the latest project we can see as well the increased use of 3D printing in this field for more innovative designs with this particular gripper capable of being used for industrial manufacturing or food production.

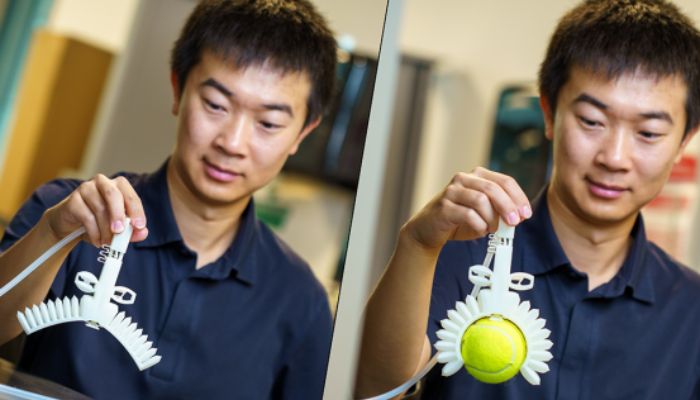

The gripper was 3D printed in one part and does not need electronics to work (photo credits: University of South Carolina San Diego)

3D Printing a Gripper Without Electronics

This particular project was published in a recent issue of Science Robotics and was done in collaboration with BASF. The team of roboticists includes Yichen Zhain, Jioayao Yan, Benjamin Shih and Michael T. Tolley from UCSD and Albert De Boer, Martin Faber, Joshua Speros and Rohini Gupta from BASF. The soft robotic gripper was designed to be used right off the 3D printer, no assembly required, and equipped with built-in gravity and touch sensors, allowing it to pick up, hold and release objects. Indeed, a key part of the 3D printed gripper is that the fluidic logic essentially allows the robot to remember when it has grasped an object. Then, when it detects the weight of the object pushing to the side, it will release it.

Yichen Zhai, a postdoctoral researcher in the Bioinspired Robotics and Design Lab at the University of California San Diego and the leading author of the paper, explained, “We designed functions so that a series of valves would allow the gripper to both grip on contact and release at the right time. It’s the first time such a gripper can both grip and release. All you have to do is turn the gripper horizontally. This triggers a change in the airflow in the valves, making the two fingers of the gripper release.”

To create such an innovative object, of course an innovative process was also required. In this case, 3D printing was chosen. However, in order to overcome previous issues with 3D printed soft robots, notably their stiffness and propensity for leaks, the team created their own 3D printing method. According to a press release from UCSD this method involved having the printer nozzle trace a continuous path through the entire pattern of each layer printed, similar to drawing a picture without lifting the pencil off the page. This not only allowed for the creation of the 3D printed gripper in one go, but reduced the likelihood of leaks and defects while also allowing for the printing of thin walls and complex, curved shapes. You can learn more about the project in the video below or in the research paper HERE.

What do you think of this 3D printed gripper? Do you know of other applications for 3D printing in the world of soft robotics? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: University of California San Diego