A New 3D Bioprinting Technique to Create Vascularized Human Tissue

A research team from the Jacobs School at the University of California, San Diego, are developing a new method of 3D bioprinting based on digital light processing (DLP). The project aims to create vascularized 3D-engineered tissues that, although produced in a lab, function as human-like living cells with biomaterial structures. The experimental study was published in Science Advances and explained in detail how the researchers successfully discovered one of the most promising types of 3D printing with biocompatible materials.

DLP 3D printing is one of the most widely used technologies in the medical sector. The implementation of this manufacturing method has great potential for biomedical applications. Some of these applications include drug development, organ transplantation, and regenerative and personalized medicine, among others. For some time now, this health sector branch has been limited by practical and technical aspects of additive manufacturing. These challenges include, for example, printing tissues with finely resolved structures and high cell densities. However, the Jacobs School team has opted for a different approach.

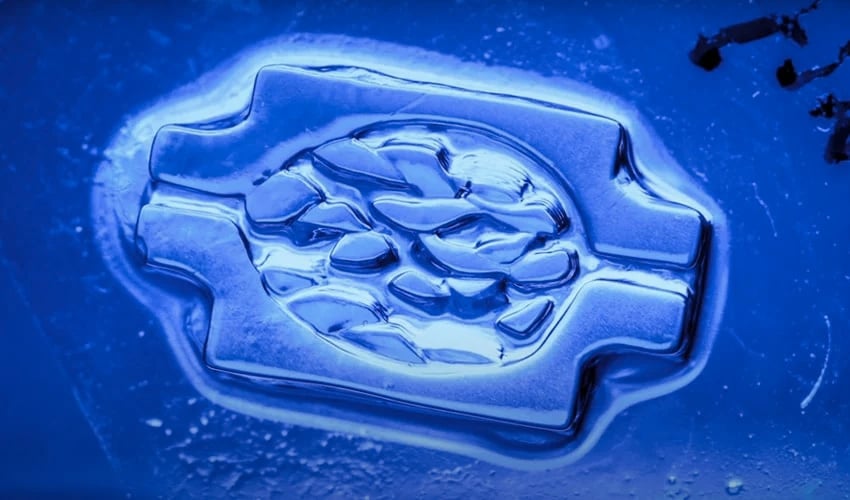

By reducing bio-ink density, light scattering is avoided (Credits: UC San Diego / David Baillot)

Creation of Vascularized Human Tissues

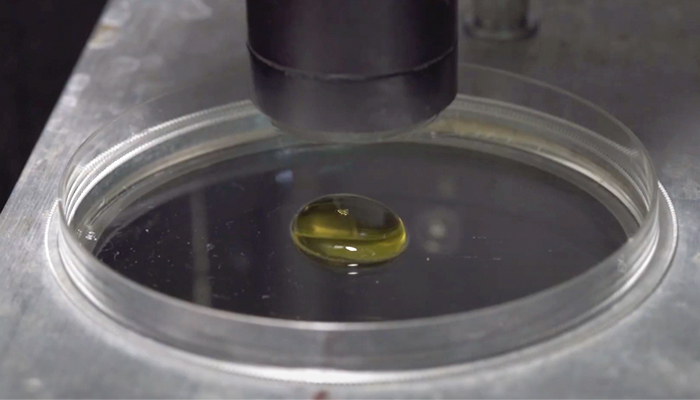

The nanoengineering team realized a 3D bioprinting system for vascularized human tissues. The patented technology is based on additive layering using cells and biopolymers to create biological structures and tissues. Generally, the higher the density of the bio-ink, the more light is scattered, which hinders the resolution of the print. To do this, the researchers obtained a biocompatible polymer for high-resolution DLP 3D printing. In this way, they reduced the light scattering effect tenfold and were able to print with high cell densities and high resolution, thanks to the contrast agent ‘iodixanol’ (a new ingredient in bio-ink).

A repeated complex process follows this until a series of layers is obtained to form the model. Here, the refractive index of the bio-ink must be adjusted to minimize the scattering effect and significantly improve the manufacturing process. The researchers achieved 50 µm with a bio-ink based on gelatin methacrylate (GelMA), whose refractive index corresponds to a cell density of up to 0.1 billion/mL. Professor Shaochen Chen, who led the project, explains: “After printing, we culture the construct to allow the cells to mature or reorganize into a functional tissue. Therefore, the cell is like a seed, and each cell type has a specific density at which they are most potent to sprout.”

The research could accelerate and strengthen the integrity of drug development and alleviate organ donor shortages and immune rejection challenges. In the not-too-distant future, this technology could make it possible to develop in vitro tissue models with high cell density. In the meantime, you can view the full study published in Science Advances HERE.

What do you think of the new method for creating vascularized human tissues? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover photo credits: UC San Diego / David Baillot