Netfabb: The 3D Printing Software for Manufacturing Preparation

Autodesk offers multiple modeling software solutions, the most well-known being AutoCAD. It is the design software of choice for architects, engineers and construction professionals. Even though you can create 3D models with solids, surfaces and mesh objects on AutoCAD, it is much more advanced in terms of its 2D capabilities. Nevertheless, Autodesk offers other solutions fully dedicated to 3D applications such as Netfabb, Fusion 360 and TinkerCAD. While Fusion 360 offers complete CAD (Computer Aided Design), CAM (Computer Aided Manufacturing) and CAE (Computer Aided Engineering) tools, Netfabb has been specifically developed for additive manufacturing, design and simulation to streamline workflows and reduce build errors before fabrication. Originally developed by German company netfabb GmbH, Autodesk acquired it in 2015.

Netfabb’s main features include converting and importing models from different CAD applications, creating models that take advantage of AM, and maximizing the number of parts you can fit into each build. Therefore, it is a 3D printing software where it is possible to move seamlessly from design to manufacturing. We could divide most of its features into four categories: the first being build preparation, the second being design optimization for additive manufacturing, the third being machine integration, and finally, simulation. For those that already design 3D parts on Fusion 360, taking advantage of Netfabb’s features will be quite simple as the former supports a direct connection. From the Fusion 360 add-in menu, you will be able to download it easily.

Netfabb is a 3D printing software to move seamlessly from design to manufacturing.

Netfabb: Preparing for Additive Manufacturing

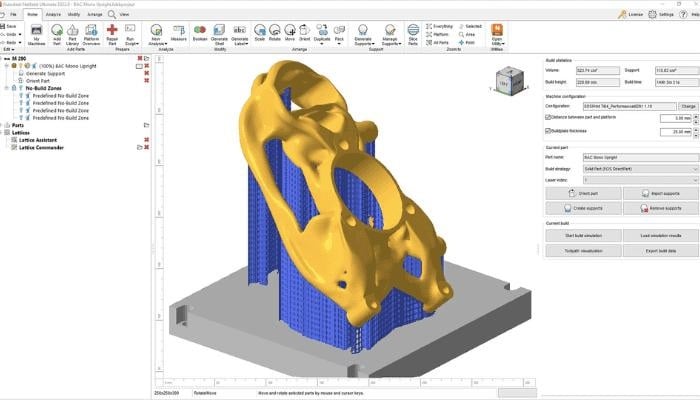

Converting a 3D model into a 3D printed part involves many steps of varying complexity, which is why Netfabb software has been designed. To help professional users prepare for printing, many additional functions have been included. The simplest functions concern construction preparation, such as importing, analyzing and repairing CAD models imported into the software. But they also include modifying models for production by adjusting wall thickness, smoothing rough areas and using semi-automatic tools that identify where you need supports.

Furthermore, users can customize reports including information for manufacturing and quotations or use advanced toolpaths to achieve optimum surface quality, maximum density and part speed. In addition, algorithms are available to efficiently position parts in the print volume. Finally, an automation feature lets you simplify common preparation tasks, such as importing, analyzing, repairing, compacting, creating sections and tool paths.

Netfabb provides design optimization tools that you can apply to your 3D models

Given the design freedom enabled by additive manufacturing technologies, it makes sense that Netfabb provides design optimization tools that you can apply to your 3D models. These tools are part of the second family of features: design optimization for additive manufacturing, and include internal lattice structures, topological optimization, integrated performance analysis, and an optimization engine to meet load requirements and reduce weight. You can use the selective spatial structure feature to fill volumes with standard or custom structures, creating unique properties for your part material.

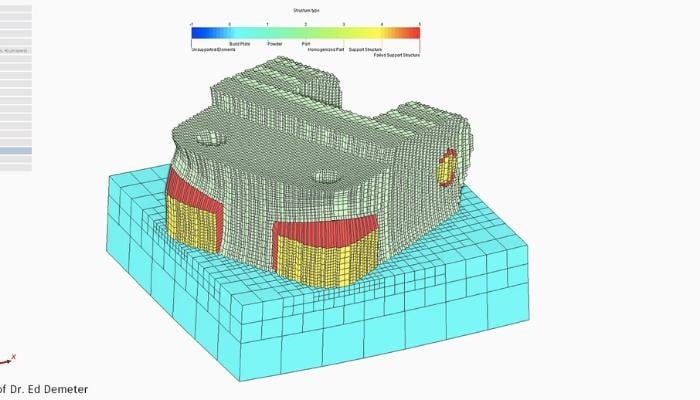

Finally, simulation is an important feature of this software. For example, Netfabb’s simulation capabilities will allow you to predict the thermomechanical response of additive parts during the metal powder bed fusion (PBF) and directed energy deposition (DED) manufacturing processes. The aim is to reduce build failures as much as possible by predicting how parts might be affected by sensitive manufacturing processes like those for metal parts.

The simulation features are quite advanced on Netfabb

Netfabb is available in Premium, Ultimate, and Simulation versions. Ultimate and Premium versions now include access to Fusion 360, Fusion Team, and additional features with Fusion 360 Extensions. For those already designing 3D parts on Fusion 360, taking advantage of Netfabb’s features will be easier, as the former supports a direct connection. You can download it easily from the Fusion 360 add-on menu. The price plan will depend on the version you choose, but to give you an idea, the Premium version costs $5,300 for one year. Prices for the Ultimate and Simulation versions are not announced on the website, so you’ll need to contact Autodesk directly. You can find more information on the full features of each version HERE.

What do you think of Netfabb? Have you ever used the software? Let us know in a comment below or on our Facebook and Twitter page! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

*All Photo Credits: AutoDesk