Nefilatek and its 100% recycled 3D printing filament

Nefilatek is a young Canadian company that has just launched its range of 100% recycled 3D printing filaments. Founded in 2018 after a successful Kickstarter campaign, the startup aims to offer more environmentally friendly materials and make 3D printing a more sustainable manufacturing method. Nefilatek thus joins the various projects combining sustainability and additive manufacturing, which are more and more numerous on the market. A recent report evaluated that filaments with eco-friendly properties would grow massively in the next 5 years. We met the founder of this startup, Bastien Lepoutre, who explained to us the process of creating recycled filaments and the future of recycling and 3D printing.

3DN: Can you introduce yourself and your link to 3D printing?

I just graduated as a mechanical engineer a month ago. Passionate about sustainable development since my childhood, I discovered 3D printing at the beginning of my studies. I have developed some personal and school projects involving 3D design and printing; this is how I joined this great 3D printing community.

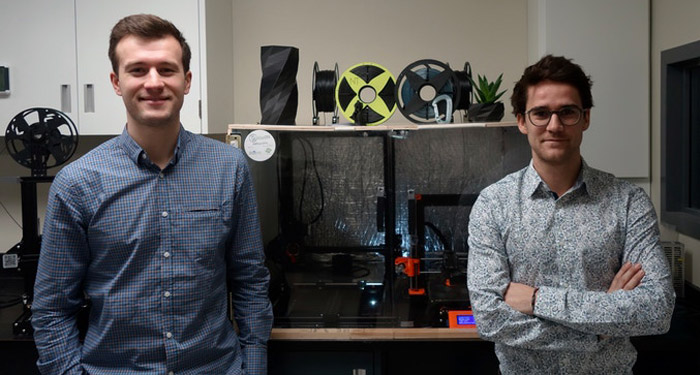

On the left, Bastien Lepoutre – founder of Nefilatek, and Angel Chauffray – partner & R&D engineer | Photo Credits: Nefilatek

3DN: How did the idea of creating Nefilatek come about?

We were really excited about using 3D printing, we are convinced that it is a technology of the future. However, it is problematic because it uses a lot of energy and plastic, which is not coherent with my vision of sustainable development. As a result, we started looking for another way to make and see how we could reuse recycled plastic in this printing process.

3DN: Can you tell us more about the process of creating 3D printing filaments?

First, we need to find waste that can be recycled, which means homogeneous waste. Secondly, we grind this waste into pellets. These go through a decontamination process to remove impurities and make the plastic homogeneous.

Then we extrude the granules into filaments; they are filtered during extrusion to remove any remaining impurities. Then the coils are cleaned and shipped. We have chosen reusable reels to avoid throwing them away when there is no filament left.

Photo Credits: Nefilatek

3DN : On which machines are your filaments compatible?

Our filaments are compatible with most FDM 3D printers on the market because we manufacture 1.75 mm filaments; we do not currently have any needs that would justify the creation of another diameter (2.85 mm for Ultimaker for example), but we have the ability to do so if necessary.

For the moment, we are selling HIPS and our PC will be ready soon. For HIPS, you need a printer with a heating plate and an extruder that can reach 250°C. For polycarbonate, you will need a closed enclosure, a heating plate up to 125°C and a metal nozzle capable of reaching 290°C.

3D printed pieces using Nefilatek filament | Photo Credits: Nefilatek

3DN: Do you think 3D printing is more durable than other manufacturing methods?

It depends on which application we are talking about: for repair, rapid prototyping or even small series production, I think this technology is more durable than other methods. In addition, 3D printing makes it possible to produce lighter parts, which means less material used and more efficiency. 3D printing is even more durable with our filaments.

However, we must be careful because 3D printers require a lot of energy per part compared to a conventional injection process. As a result, it is a method that will not be as interesting in terms of sustainable development for mass production.

For the moment, only HIPS is offered | Photo Credits: Netfilatek

3DN: What are your future projects?

Our next objective is to develop more 100% recycled filaments such as ABS, PLA, PP or Nylon in order to offer a wide variety of materials to our customers. We are also working on a small production farm that will work with our 100% recycled filaments. The objective is to offer people 100% recycled objects made with our filaments.

3DN: Any last words for our readers?

Feel free to contact us if you are interested in our 100% recycled filaments! And don’t forget to let your imagination run wild!

What did you think of Nefilatek? Let us know what you think in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!