NC State Researchers Develop Novel 3D Printable Jelly

Over the years, researchers have combined 3D printing and hydrogels for a variety of different innovative projects including a lifelike model of a human heart, cancer treatment, artificial muscle tissue able to adapt its color and shape according to light, and even biocompatible hydrogel models. Now, a team of researchers from North Carolina (NC) State University has combined two physical forms of the same seaweed material to create a homocomposite hydrogel with improved and highly controlled properties. According to the university this method could have applications in biomedical materials. For example, soft robotics, biological scaffolds for growing cells, strengthened 3D-printed bandages or even patches for wound healing or drug delivery.

Hydrogels are 3D printable, water-based substances resembling jelly. Typically, they are composed of chemical compounds found in seaweed and algae, often used as thickening agents and in wound dressings, called alginates. Hydrogels are a distinctly useful material for the reason that they are, at once, both strong and flexible. The possession of both these qualities is possible, as Orlin Velev, S. Frank and Doris Culberson Distinguished Professor of Chemical and Biomolecular Engineering at NC State and corresponding author of the paper explains, because “water-based materials can be soft and brittle”. It is thanks to this quality that hydrogels are well suited to such a wide range of applications.

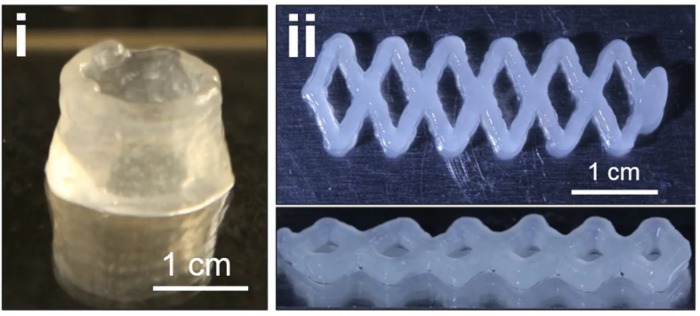

Images of extruded homocomposite hydrogel paste that has been layered in 3D. (Photo Credit: NC State University)

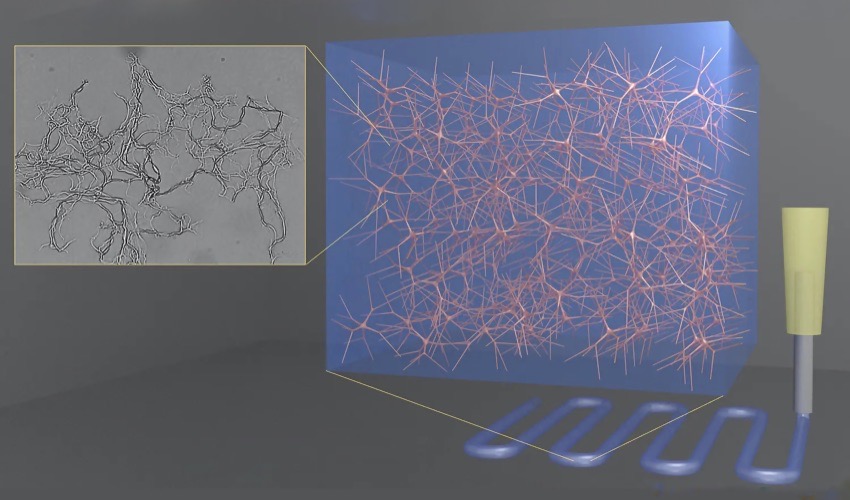

However, the hydrogels developed by NC State were created by merging micro- and nano-sized networks of the same materials harnessed from seaweed and are thus homocomposite materials. They are therefore distinct from typical hydrogels for the reason that they being “soft fibrillar alginate particles inside a medium of alginate – are really two hydrogels in one: one is a particle hydrogel and one is a molecular hydrogel. Merged together they produce a jelly-like material that is better than the sum of its parts, and whose properties can be tuned precisely for shaping through a 3D printer for on-demand manufacturing.”

According to the team, they were able to eradicate the fragility that can occur when merging differing materials in hydrogel, by merging different-size scale networks of the same alginate instead. “We are reinforcing a hydrogel material with the same material, which is remarkable because it uses just one material to improve the overall mechanical properties,” commented Lilian Hsiao, an assistant professor of chemical and molecular engineering at NC State and a co-author of the paper. In the future the researchers hope to advance 3D printing for biomedical applications or biomedical injection materials by fine-tuning their method of merging homocomposite materials. If you want to find out more information you can read the full paper HERE.

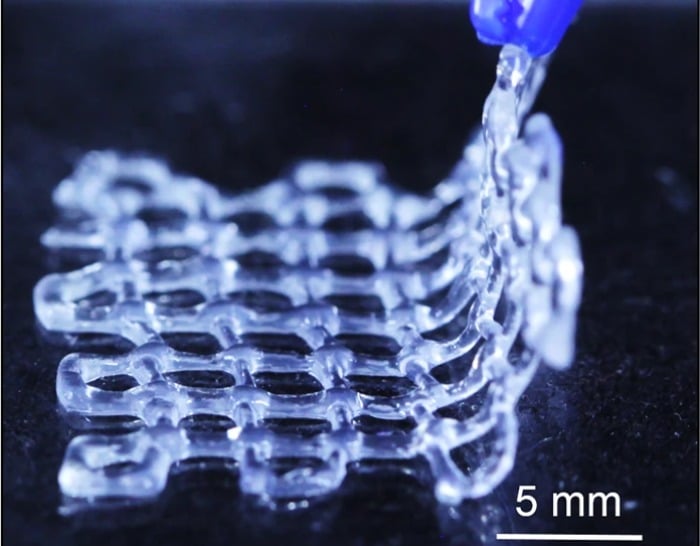

Removal of the equilibrated hydrogel design from the substrate. The structure is strongly self-reinforced. (Photo Credit: NC State)

What do you think about these homocomposite hydrogels developed by NC State University? Let us know in a comment below or on our Facebook, Twitter and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!