NASA’s SpaceX-33 Mission Brings 3D Printing Technologies to Space

In late August, NASA and SpaceX launched the 33rd commercial resupply mission to the International Space Station (ISS). The mission, carried out with the reliable Dragon capsule, transported not only the usual supplies but also a wide range of innovative scientific experiments. At the center of attention and of particular interest to us were groundbreaking applications of 3D printing technologies in medicine and aerospace engineering.

Medical Implants and 3D Bioprinting

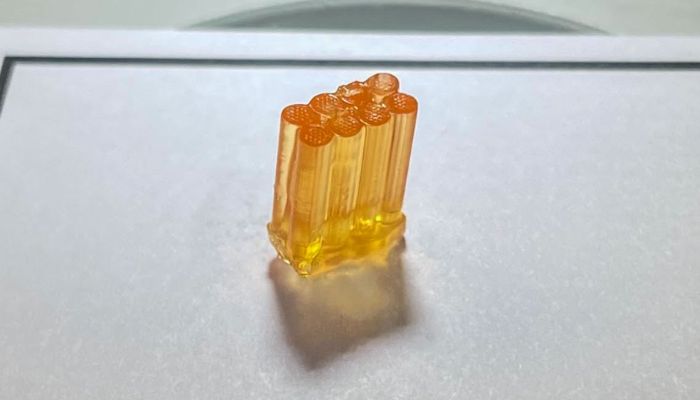

One of the most fascinating experiments of the current mission is the attempt to produce medical implants using 3D bioprinting under the unique conditions of microgravity. Researchers hope, among other things, that nerve cells may regenerate more effectively in weightlessness. The implant developed specifically for these tests is intended to help bridge nerve pathways damaged by accidents and thereby support healing processes in the human body. On Earth, previous methods have often failed to create stable ‘bridges’ between injured nerves. The implant produced in space could not only be of higher quality but also provide new insights into the regeneration of nerve cells.

The Nerve Bridge

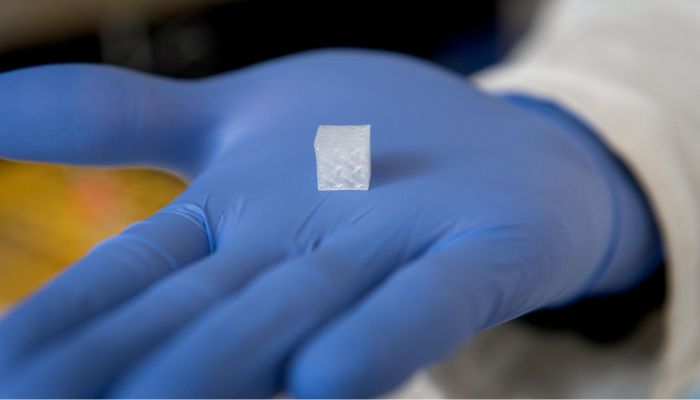

Another highlight of the mission is the study of 3D-printed liver tissue. After earlier tests already showed that the tissue can withstand conditions in space, scientists now want to move on to the next phase. This includes testing active cell growth behavior and documenting blood cells within the 3D-printed liver tissue. ‘We are particularly interested in accelerating the development of vascular networks in the tissue,’ says James Yoo of the Wake Forest Institute for Regenerative Medicine. The long-term goal of this research is nothing less than the 3D printing of functional human organs, which is still a distant dream in medical technology.

3D Printed Liver Tissue

Metal 3D Printing in Space: Spare Parts from Orbit

Alongside biotechnological experiments, technical 3D printing also plays a key role. The farther space missions travel from Earth, the more difficult it becomes to deliver necessary spare parts or components. For this reason, developing local manufacturing capabilities in space is of crucial importance. In collaboration with Airbus Defence and Space SAS and CADMOS in France, the European Space Agency (ESA) is testing various strategies for metal printing in microgravity. As Rob Postema explains: ‘We will print several small cubes with different strategies to identify the optimal approach for metal printing in space, as well as two small nozzles to examine the quality of spacecraft parts printed in microgravity.’

Beyond 3D printing technologies, researchers are also studying bone cells to counteract the severe bone loss experienced by astronauts in space. The current mission includes experiments with bone-forming cells to better understand the impact of microgravity on their growth and to potentially develop countermeasures. The SpaceX-33 mission thus promises to provide an innovative research environment for forward-looking technologies. All participating partners are setting a new benchmark for the use of 3D printing in space. More information can be found HERE.

What do you think of the SpaceX-33 mission? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel. For more 3D printing news in the aerospace and defense sectors, check out our dedicated page HERE.

*All Photo Credits: NASA