NASA and ORNL Have Used 3D Printing to Create Moon Rover Wheel Prototype

Oak Ridge National Laboratory has succeeded in 3D printing a lunar rover wheel based on a NASA design. This has been possible thanks to a newly developed and specialized 3D printer which they used to create parts designed specifically for space exploration. The wheel in question will be tested by NASA to compare its performance with that of the traditionally manufactured wheels that are currently on their new lunar rover.

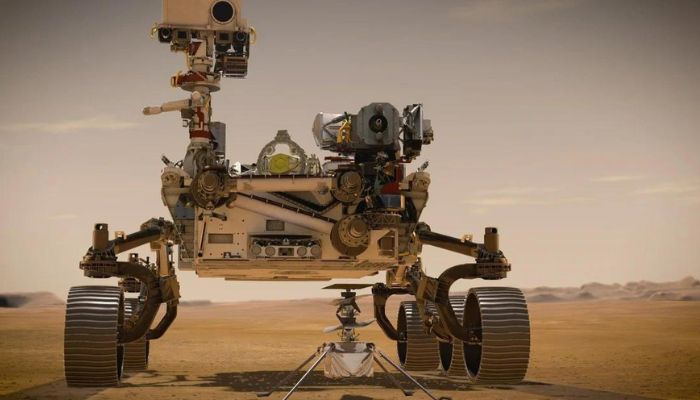

NASA has been preparing for some time an operation with the mission to map the south pole of the moon. Indeed, though it may seem less important than other projects from the organization, this mapping is a determining factor in learning how water is distributed on the Moon. Therefore providing information on whether it is able to collect enough water for people to inhabit the lunar surface. The vehicle for this mission is the Volatiles Investigating Polar Exploration Rover, or VIPER, which will be equipped with a new wheel design. These same wheels are the ones that have been 3D printed to meet the same design specifications in order to directly see how additive manufacturing could be used for this type of project in the future.

The rover that NASA plans to send to the Moon

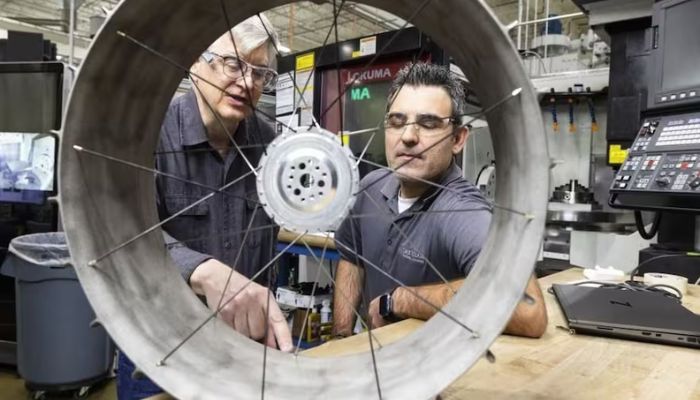

The 3D printed prototype wheels are made of a nickel alloy. They have a diameter greater than 50 cm, which for a part made using metal powder bed fusion is considerably large. Not only that, but by using additive manufacturing, it is possible to create a part that is even more complex than the original in as little as 40 hours with no additional costs or difficulties in the manufacturing process. Its only drawback is the weight, as it weighs 50% more than the original wheel. But if NASA is able to prove that the 3D printed prototype is as robust as the original, the next generation of these rovers could carry these rims.

The Future of the 3D Printers Used to Make the Lunar Rover Wheel

Peter Wang, who leads the development of new laser powder bed fusion systems, firmly believes that the printer used is unique in its ability to print large objects simultaneously and continuously. The printer in question employed two lasers coordinated with each other and a rotating printing plate. Wang, notes that “This dramatically increases the production rate with the same amount of laser power. We’re only scratching the surface of what the system can do. I really think this is going to be the future of laser powder bed printing, especially at large scale and in mass production.”

Prototype of a 3D printed wheel for the NASA rover

Moreover, thanks to this achievement, there has been new interest in printing other parts. Brian Gibson, the researcher who led the project, added, “Additive manufacturing offers the flexibility that if you have the feedstock, you could make any replacement part you need, whether in space or on Earth.” Thus clearing up doubts about rumors that 3D printers were being considered for the Moon or Mars, with the possibility that these printers would use local raw materials from the red planet or the Earth’s satellite in their 3D prints. You can find out more about the project HERE.

What do you think of this 3D printed wheel prototype for NASA’s lunar rover? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Carlos Jones/ORNL, U.S. Dept. of Energy