NASA and Aerojet Rocketdyne Partner to Test AM Hardware

NASA has announced that its Robotic Deposition Technology (RDT) team is partnering with Aerojet Rocketdyne, an American rocket and missile propulsion manufacturer headquartered in Sacramento, to advance its 3D printing, and more specifically metal additive manufacturing, technologies. NASA also hopes that this partnership will aid in the advancement of its capabilities for liquid rocket engines in landers and on-orbit stages/spacecraft. With Aerojet Rocketdyne, NASA’s RDT team has manufactured rocket engine hardware which has successfully passed both cold spray and hot fire tests.

Led out of NASA’s Marshall Space Flight Center in Huntsville, Alabama, the team has been designing and manufacturing innovative and lightweight combustion chambers, nozzles, and injectors that will incorporate automated robotic deposition 3D printing technologies. These include cold spray deposition, laser wire direct closeout, laser powder bed fusion, and laser powder directed energy deposition. With this work NASA intends to evolve these processes using weight-optimized materials to validate operability, performance, and reusability through hot fire testing.

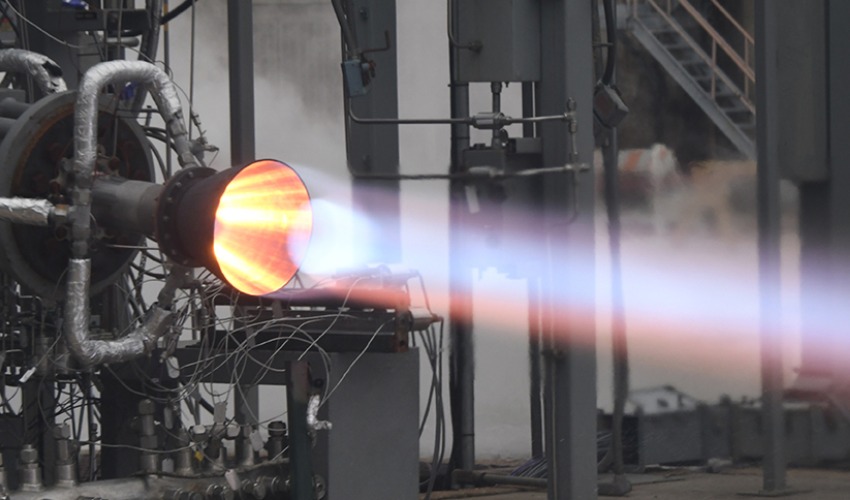

3D-printed bimetallic lightweight thrust chamber assembly before hot fire testing at NASA’s Marshall Space Flight Center in Huntsville, Alabama. (Photo Credits: NASA)

Last year, the RDT team tested hardware such as injectors and carbon composite nozzles and hot fire testing its 3D printed lightweight combustion chamber and nozzle under the Long Life Additive Manufacturing Assembly, or LLAMA, project. Together with Aerojet Rocketdyne, NASA has now finished testing hardware under a second lamoid-named project – the Advanced Lander Propulsion Additive Cold-spray Assembly, or ALPACA, project. According to Thomas W. Teasley, an engineer at the Marshall Space Flight Center “Testing of the RDT Advanced Lander Propulsion Additive Cold-spray Assembly (ALPACA) chamber went very well and demonstrated a new technology capability for NASA and industry partners”.

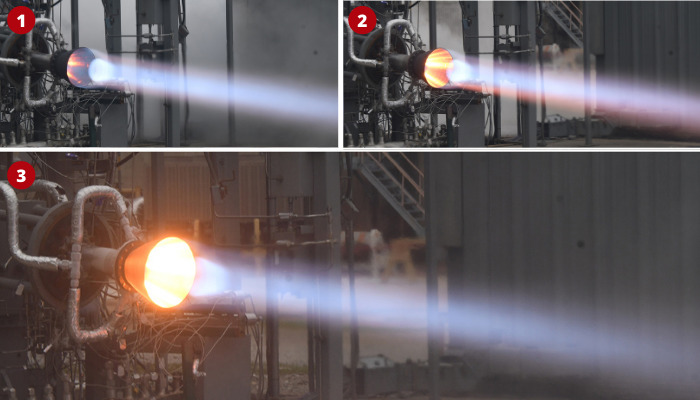

During the testing “the hardware accumulated eight starts at 365.4 seconds of total hot fire duration”. NASA also reported that “the combustion chamber experienced pressures up to 750 pound-force per square inch (psi) for all tests conducted as well as calculated hot gas temperatures approaching 6,200 degrees Fahrenheit”. There were also an additional three different carbon composite nozzles designed for 7,000 pounds of thrust that were tested. According to the team, these demonstrated a capacity “to endure extreme environment conditions with measured nozzle temperatures of more than 4,000 degrees Fahrenheit in testing. To put simply, the hardware was successfully exposed to extreme pressures, temperatures and other conditions that parts must be able to withstand in order to function properly in space”.

The Robotic Deposition Technology team completed the first phase of testing a 3D-printed metal thrust chamber assembly at NASA’s Marshall Space Flight Center in Huntsville, Alabama. Numbers show order of occurrence. (Photo Credits: NASA)

According to Aerojet Rocketdyne Senior Engineer Bryan Webb “The RDT ALPACA effort between NASA and Aerojet Rocketdyne is another example of our collaboration and partnership in advancing additive manufacturing technologies”. These advancements in additive manufacturing technologies enable the provision of more lightweight and cost-efficient liquid rocket engine parts rather than the typically heavy and more complex traditional hardware. This in turn functions to benefit both NASA and commercial space missions in the future.

If you want to find out more information you can read the full press release HERE. What do you think about NASA’s ALPACA project? Let us know in a comment below or on our Facebook, Twitter and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!