NASA Is Looking to Advance the Use of Metal 3D Printing for Spaceflight

It is common knowledge that additive manufacturing is extremely useful right here on Earth, but what about in outer space? For some time now, 3D printing has been considered to be one of the leading technologies for applications related to space exploration. And that has been reconfirmed recently. NASA has announced that out of its two new Space Technology Research Institutes (STRIs), one will be dedicated entirely to the understanding and rapid certification of metal parts made using additive manufacturing technologies.

NASA is certainly no stranger to the use of 3D printing technologies. The agency has been a long-time adopter of AM, testing its capabilities for a variety of applications including the creation of rocket parts, 3D printed foods on the ISS and even the possibility of construction on extraterrestrial bodies. But this announcement shows even more clearly its commitment to the integration of new and innovative technologies like 3D printing as a way to advance its long-term exploration goals. Each institute will be led by teams at U.S. universities to create “multidisciplinary research and technology development programs critical to NASA’s future.” For this work, they will each receive up to $15 million over five years.

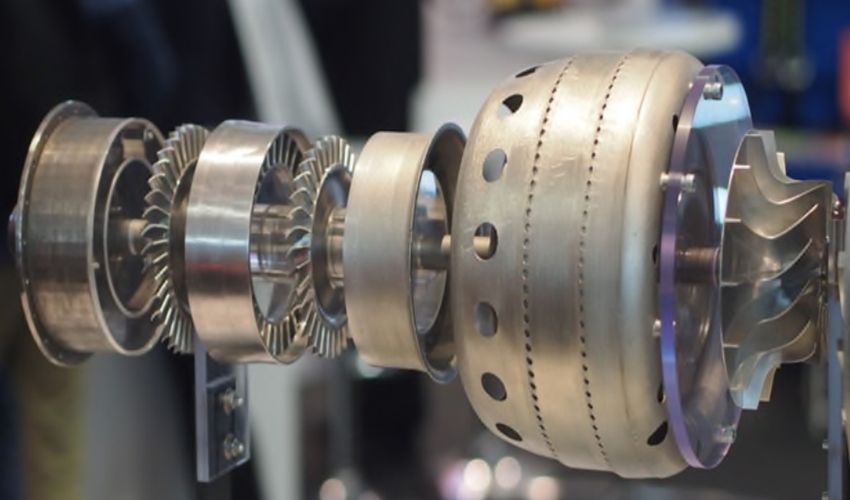

One of the STRIs will be dedicated to understanding and certifying metal 3D printed parts for spaceflight (photo credits: NASA)

Jim Reuter, associate administrator for the agency’s Space Technology Mission Directorate at NASA Headquarters in Washington, further explained, “We’re thrilled to draw on the expertise of these multi-university teams to create technology for some of our most pressing needs. Their work will enable next-generation science for studying our home planet and broaden the use of 3D-printed metal parts for spaceflight with state-of-the-art modeling.”

What Can We Expect From the Institute for Model-Based Qualification & Certification of Additive Manufacturing?

But how exactly will AM be studied? Well, the institute in question will be the Institute for Model-Based Qualification & Certification of Additive Manufacturing (IMQCAM), co-led by the Carnegie Mellon University in Pittsburgh and Johns Hopkins University in Baltimore. As its name suggests, its purpose is to improve the computer models of 3D printed metal parts in order to expand spaceflight applications and improve qualification and certification of parts. This will be done by using digital twins to help engineers understand the parts’ capabilities and limitations, including how much stress the parts can take before breaking.

These high-accuracy predictions of characteristics of metal 3D printed parts will be critical for learning about part properties before they are even made, thus making it a key part of certification later on. Additionally, these digital twins will be made from spaceflight materials that are already commonly used for 3D printing, such as the NASA-developed copper-chromium-niobium alloy GRCop-42. Scientists will also be able to use these models to evaluate and model new materials for space applications.

Tony Rollett from Carnegie Mellon will serve as one of the co-directors of the project (photo credits: Carnegie Mellon University)

“The internal structure of this type of part is much different than what’s produced by any other method,” expands Tony Rollett, principal investigator for the institute and US Steel professor of metallurgical engineering and materials science at Carnegie Mellon University. “The institute will focus on creating the models NASA and others in industry would need to use these parts on a daily basis.” Considering that certification and qualification is often mentioned as one of the biggest obstacles for the use of additive manufacturing for end-use parts in safety critical sectors like aerospace, this could go a long way to furthering its use for a variety of applications. You can learn more about the IMQCAM in the press release from NASA HERE.

What do you think of this move by NASA? Do you think additive manufacturing will continue to be important for the future of space exploration? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: NASA