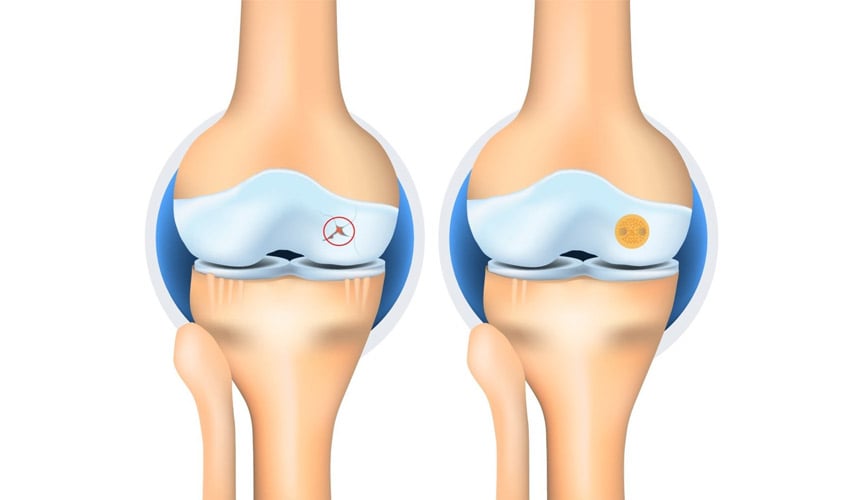

Nanochon 3D Printed Implants Repair Knee Cartilage

Founded in 2016, Nanochon aims to facilitate cartilage replacement and repair for patients suffering from knee injuries. It relies on 3D printing technology, specifically extrusion, to manufacture an implant that replaces lost or damaged cartilage. In this way, Nanochon offers an alternative to arthroplasty, a method that is often painful for patients and involves a very long convalescence. Called Chondrograft™, this 3D-printed device is made from an innovative biocompatible composite material that promotes tissue growth. We caught up with one of Nanochon’s co-founders and CTO, Nathan Castro, to find out more about this implant and the company’s prospects.

3DN: Can you introduce yourself and your connection to 3D printing?

My name is Nathan Castro and I’m co-founder and CTO of Nanochon, Inc. We’re developing a 3D-printed synthetic implant for cartilage resurfacing and repair in the patellofemoral (knee) joint. I discovered additive manufacturing and 3D printing in the mid-2000s, during my undergraduate studies at the University of Texas-El Paso, while participating in an undergraduate research program at the W. M. Keck Center for 3D Innovation. I focused on the synthesis of biocompatible resins for stereolithography. I continued my interest in stereolithography during my PhD, during which I built a table top system and extended my research to musculoskeletal tissue regeneration.

Nathan Castro, co-founder and CTO of Nanochon

3DN: How did Nanochon come into being, and what is its objective?

Nanochon is a spin-off from George Washington University, where co-founder Ben Holmes and I completed our doctoral studies in regenerative medicine. We were introduced to entrepreneurship through the local NIH I-Corps (DC), where we conducted several customer discovery interviews to test our technologies. At the end of the program, we decided to join forces and Nanochon was created. Our aim is to address the unmet need for effective and efficient cartilage repair using a materials and mechanics-based approach.

3DN: How are Nanochon implants produced?

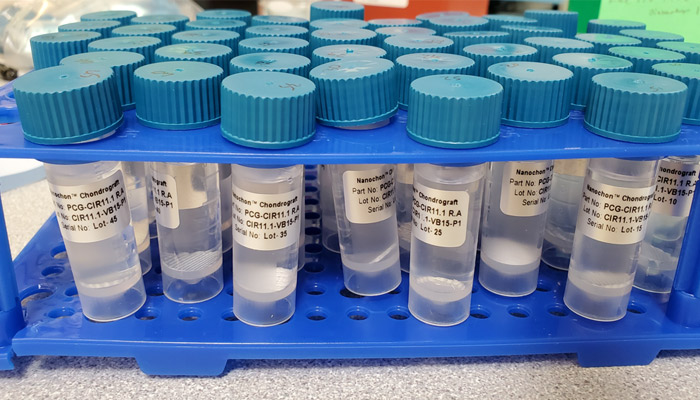

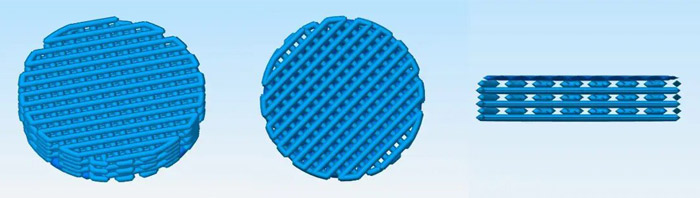

Nanochon’s ChondrograftTM is additively manufactured by fusing filament from our proprietary biocompatible composite material. The raw microstructure is created by the 3D printer path. In addition to the visible microstructure, ChondrograftTM also features submicron porosity which, after post-processing, results in a softer, more malleable device while retaining its integrity. Our aim is to address the unmet need for effective and efficient cartilage repair by applying a material and mechanical approach. What sets Nanochon apart from the rest is our unique 3D-printable material, which produces a mechanically robust and biocompatible implant.

The 3D printed implants

3DN: What are the main advantages of additive manufacturing for Nanochon?

We believe additive manufacturing offers a multitude of benefits, particularly for small start-up companies like Nanochon. Here are some of the specific advantages: 1) it enables rapid iteration and design testing; 2) it offers cost-effective small- to medium-scale manufacturing; 3) it enables capital investment to be managed thanks to the variety of FFF printers available and the robustness of these systems, enabling good levels of reproducibility and repeatability.

3DN: What should be considered when using 3D printing in the medical field?

In our experience, it’s important to speak to competent people in this field. Regulatory guidance is particularly important, as additive manufacturing is still a relatively new field for the direct manufacture of medical devices. Although guidance documents exist, they are only guides and are open to interpretation. Being in touch with people with direct experience will minimize unnecessary obstacles. Market size and product design are also important considerations. Nanochon positions ChondrograftTM as a ready-to-use implant suitable for a wide range of patient categories. The possibility of a customized or standard product should be considered and evaluated to determine the most fiduciary course of action.

The 3D printed implant promotes cell growth

3DN: How do you see the future of additive manufacturing in medicine?

I firmly believe that the future of additive manufacturing in medicine is bright, and that as the technology continues to mature, new materials become available and existing materials are reused, there are still avenues to explore.

3DN: Any final words for our readers?

From a personal point of view, additive manufacturing has awakened the inventor in me by providing me with a tool that allows me to be creative and test my ideas. A small investment can pay big dividends. Not just financially, but spiritually too. Find out more about Nanochon HERE.

What do you think about Nanochon’s work? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All image credits: Nanochon