Nagami, exploring the design of the future with new technologies

Nagami is a design studio based in Ávila, Spain that has become known worldwide in recent months for the presentation of Zaha Hadid Architects chairs at the Milan Design Fair or the Voxel Chair v1.0 in the Georges Pompidou Museum in Paris. The studio has made a big bet for the future: manufacture with 3D printing and robotics.

After these great developments we’ve had a growing interest in the company and we got the chance to talked with Manuel Jiménez García training architect and co-founder of Nagami. Here he talked about the main developments of the study and gave us his opinion on the evolution of design and architecture in the hand of 3D technologies.

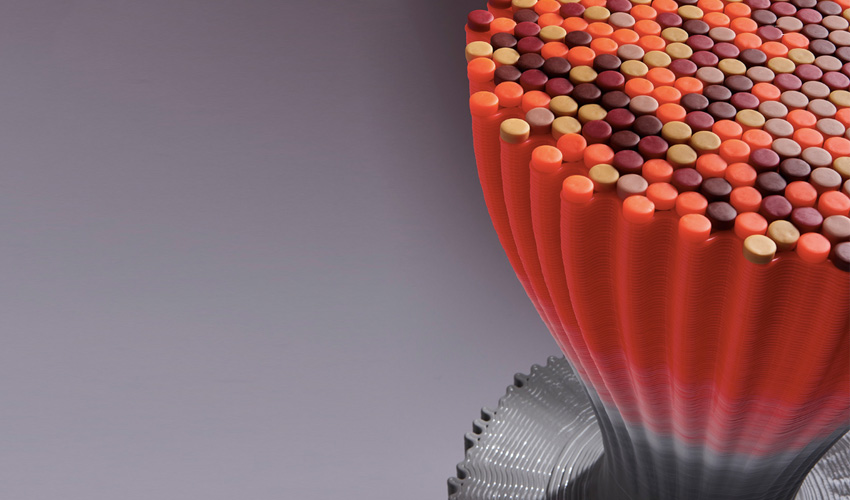

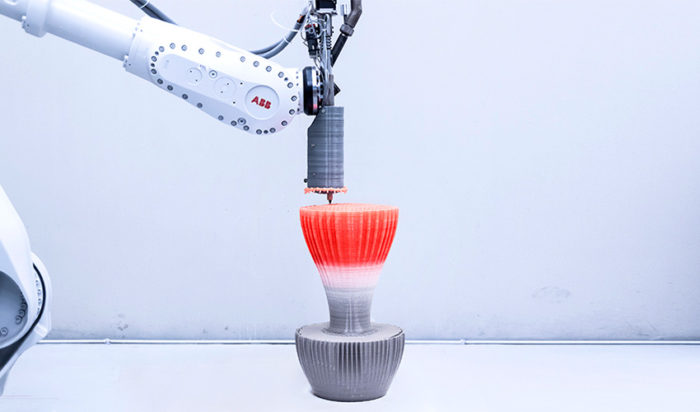

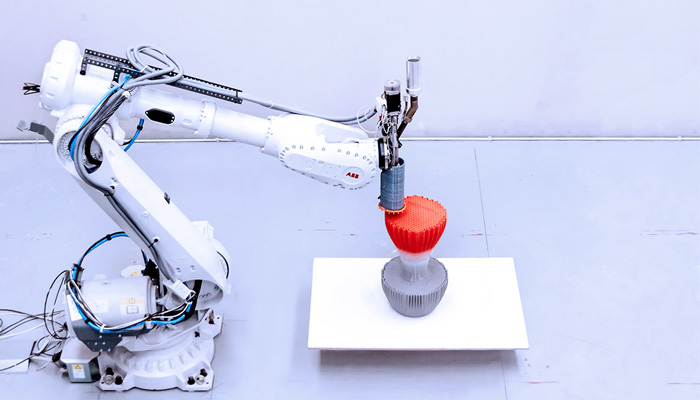

Ross Lovegrove Stool Manufacturing

3DN: Can you tell us how the idea of Nagami came about and what were its first developments?

Manuel Jiménez García co-founder of Nagami

I have been working in architecture research in London for 9 years, mainly linked to the academic field. For the last 5 years, the research laboratory that I direct at UCL The Bartlett School of Architecture, has specialised in methods of automation, one of these methods is 3D printing of large format. At the same time, Ignacio and Miki, also with a background in Architecture, were already working on the creation of a 3D printing company in Spain.

The opportunity to join forces arose when the Center Pompidou in Paris commissioned my laboratory (Design Computation Lab) for a work for their exhibition “Printing the world”. Nagami was created to develop a robotic extrusion system that facilitated the creation of this piece, with the idea of continuing towards the development of large-scale furniture, once the exhibition is over. VoxelChair v1.0 (the product developed for this event) became part of the permanent collection of the museum, and from that moment the company began its adventure in product development, which was when our first productions, such as the Nobu chairs and Estrat , and the Nital vase , came alive.

Silla Estrat – Nagami

3DN: Why have you decided to introduce additive manufacturing technologies and what techniques do you use so far?

Additive manufacturing technologies allow for formal freedoms that would be unattainable with other methods. The type of geometry that our brand promotes would have little viability if we used more traditional technologies, such as injection or blow molding, or even other numerical control technologies.

At the same time, additive manufacturing is incredibly efficient in terms of the use of materials; By only printing the material that will eventually form part of the object, the production of waste material is really minimal, and often non-existent.

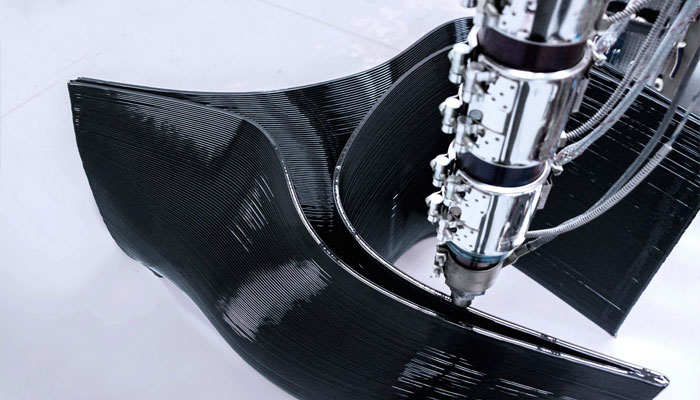

Development of the Peeler chair by Daniel Widrig

So far we are concentrating our efforts on PLA plastic extrusion. We use plastic in pellets, this reduces the cost of production considerably compared to traditional methods of 3D printing with filament. We have developed new techniques within 3D printing such as pigment gradation and variable thickness printing, which have become trademarks of the brand.

3DN: Could you tell us about Nagami’s most outstanding projects and what are the ones you have in mind for the near future?

VoxelChair v1.0 is still a very important project for us, not only because it is our first project developed at a professional level, but also because of the learning that we obtained when developing it.

Video of the the development of the VoxelChair v1.0 for the Pompidou:

Nital and Estrat also have a great significance for the brand, as they are the first accessible products using large scale printing, which is a big step in a still emerging market.

The four chairs that we have just shown in Milan have been a great laboratory of ideas for us. Each designer has introduced technical challenges that will undoubtedly facilitate the development of new products that are nurtured by these innovations.

Nital – Nagami

In the future we would like to expand our range of products, not only reaching different scales – from small objects to elements linked to architecture and interior design – but also incorporating products that make us imagine new uses, objects that are not easily categorisable, but generate new typologies in the world of design and architecture.

3DN: How important do you think the relationship between 3D printing and design is today?

3D printing gains more importance every day for design professionals. Technology is causing a change in our production models, opening the way to more horizontal and democratic design and manufacturing methods. Thanks to 3D printing and other digital manufacturing technologies, we are slowly transforming not only our way of generating products, but also how to design companies and new research and development models. A large number of startups that are revolutionising our industry, base their principles on goals only achievable thanks to the use of 3D printing technology. We are without a doubt observing one of the biggest changes in our discipline since the industrial revolution,

Use of a robotic arm for the manufacture of Ross Lovegrove stool

3DN: Do you have any last words for our readers?

Think Big and work hard! Truly nothing is impossible if someone can imagine it.

Milan Design Fair with the chairs manufactured by the studio

For more information you can visit the official website of Nagami here.

What do you think about the 3D printed furniture? Let us know in a comment below or on our Facebook and Twitter pages! And remember to sign up for our free weekly Newsletter, to get all the latest news in 3D printing send straight to your inbox!