MYCO ALGA: 3D Printed Organic Tiles for Natural Aesthetics

Tiles made from fungi, algae and waste – the first impression may evoke skepticism and disgust, but behind this is a unique sustainability concept based on innovative technologies and sophisticated algorithms. The London and New York-based research and design studio bioMATTERS specializes in the development of bio-digital products, textiles and material systems. It uses living cells, fungi, algae, bacteria and various waste products from natural resources. The aim of designers Nancy Diniz and Frank Melendez is to respond to the challenging climate situation with innovation and to manufacture new products on a sustainable basis. One such product is the MYCO-ALGA tile system. When put together, the individual tiles create a continuous pattern of cream and green tones for a nature-like indoor ambiance.

For bioMATTERS, aesthetics and design are the top priorities of a product. Nevertheless, with MYCO-ALGA the designers not only want to promote bio-aesthetics, but also ecological practices. By demonstrating the possibilities of waste and natural organisms in product development, they want to stimulate the shift towards biomaterials. With MYCO-ALGA, they have succeeded in creating a 100% biodegradable end product that incorporates many technological elements and mathematics alongside its organic materials. Computer-aided design, robot-controlled production, cultivated and dyed by microbes – that’s MYCO-ALGA in a nutshell.

bioMATTERS is experimenting with the production of biodegradable pastes based on fungi, cell cultures, bacteria and waste.

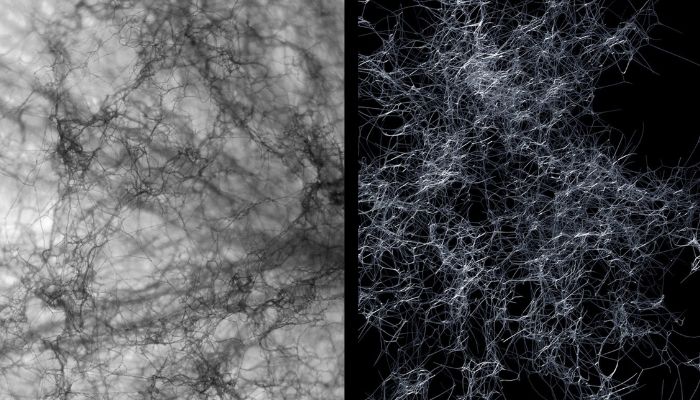

The manufacturing process is in fact a multi-layered procedure. The tiles are first digitally designed using algorithms and then 3D printed into shape. A paste based on household and industrial waste is used as the building material. This paste in turn forms the basis for the growth of a fungal network, namely mycelium. Once the tiles have been printed from this material, they are cultivated in a climate-controlled environment for around two weeks so that the mycelium grows on the tile, spreads naturally and surrounds the entire surface of the tile, holding it together. To stop the growth, the tiles are placed in an oven, where drying and dehydration begin. This makes the tile light and durable.

Following this step, comes the application of bio-pigments. These are obtained from algae biomass and are also printed onto each individual tile using a 3D printing process. This green branching on each tile provides the aesthetic finishing touch, as it is this branching shape and color that creates the complete continuous pattern of the tile system and the ultimately natural aesthetic. You can find out more about bioMATTERS, the work and MYCO-ALGA at their website HERE.

Networks of mycelial hyphae and computer simulation of network propagation.

What do you think about bioMATTERS MYCO ALGA? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

All image credits: bioMATTERS