Mycelium as a Material for 3D Printing

As plastic remains one of the most widespread materials on earth, there has been much discussion on to its impact on the climate. However, anyone who believes that plastic is the only culprit among environmentally harmful materials is mistaken. The cement industry ranks third in terms of its CO2 emissions (according to the UN Environment Program 2020) and you only have to look around to see how ubiquitous cement and concrete are in our lives. Thankfully, intensive research is being carried out into new materials that can be used as alternatives. One of these materials is mycelium or mycelium/mycelium, which is based on fungi. In combination with 3D printing, this bio-based material has great potential as an environmentally friendly construction industry and numerous applications.

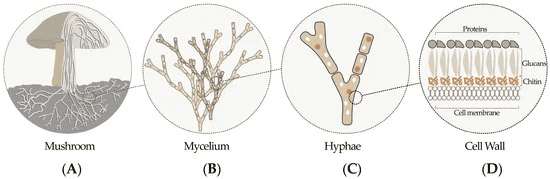

Mushroom mycelium has actually been researched as a building material for many years. To be precise, it is not the fungus itself that is used as a building material, but its root system. This is where its hyphae, the fungal filaments, are found, which fuse together and form a network, namely the mycelium. This can spread to other materials and penetrate wood or straw, for example, in order to utilize their nutrients. If the fungus also gets water, it grows. This parasitic existence is actively used to enrich the mycelium with nutrients from other materials. The mycelium then acts as an adhesive so that the mixture of materials becomes solid and can be molded – or printed.

Schematic of the root system (photo credits: Biomimicry)

Fungi are also known for their carbon-absorbing abilities. This means they can help to slow down climate change. In addition, many fungi are not particularly picky about their “feed”, so they also draw nutrients for growth from waste or residual materials, which further favors the circular economy. In this sense, mycelium-based materials can be actively cultivated.

Properties of Mycelium

Mushrooms are abundant in nature and mycelium is a renewable raw material. The processing of mycelium-based materials is cost-effective and requires little energy. The materials are also easy to dispose of at the end of their service life and are naturally recyclable. This makes mycelium an attractive, sustainable building material.

Due to its organic origin, it adapts easily to the environment and is similar to other biological materials, such as animal bones or plants. Mycelium is therefore able to regenerate and heal. For us humans, mycelium-based substances are harmless to health and are not allergenic or toxic. If it is an edible mushroom, mycelium can even be used as food.

Mycelium is considered a sustainable material for various applications (photo credits: Shape Lab – Institute of Architecture and Media, TU Graz)

Mycelium also has a wide range of physical properties. It is heat-insulating, flame-resistant and hydrophobic, but at the same time very strong and stable. For this reason, it is used for insulation and furniture. In fact, mushroom mycelium can replace a large number of materials, for example leather, wood, cardboard, polystyrene or insulating wool, and can therefore be used in a wide variety of fields.

Mycelium is already being used as a building material in architecture and for noise protection, where its self-growing properties, flame resistance and insulation are highly valued. As it can withstand heavy loads, it is also used in interior design or for furniture. It is also increasingly being used as an alternative, sustainable material in design, fashion, art and consumer goods. Its regenerative properties even allow it to be used in medicine! All these areas of application are made possible by the targeted cultivation of the mushroom mycelium and how it is processed.

3D Printing With Mycelium

3D characterized by its freedom of design and its ability to create geometrically complex structures. As it is an additive process, there is hardly any waste (depending on the process), which makes 3D printing a sustainable production method in this respect. In combination with biological materials – such as mycelium – additive manufacturing offers an opportunity to produce ecologically.

Extrusion-based processes are most commonly used in connection with mycelium, in which a mycelium composite is printed into shape as a paste. Depending on the composition of the composite material, different properties of the building material can be achieved. The mushroom material allows a great deal of creative freedom, it can have different colors, textures and patterns. However, a few steps need to be taken into account for the print to succeed.

3D printing with mycelium (photo credits: Shape Lab – Institute of Architecture and Media, TU Graz)

Overall, the printing process is very complex, as many parameters have to be adhered to. First, the mycelium is “fed” with additional raw materials, which allows it to thrive. Various materials such as wood, sawdust, paper, cardboard or even materials that are considered non-recyclable and no longer usable come into question. This mixing creates a new substrate, which is referred to as a mycocomposite, myco-material, fungus-based material or similar. Subsequently, the growth of the fungus must be controlled and the material cultivated in such a way that it has the properties required for printing. In other words, it must be flowable, elastic and malleable. Only then can 3D printing take place.

At this stage of the process, it is essential that a sterile environment is guaranteed. The mycelium is very susceptible to bacterial infestation and contamination. As it comes into contact with many components in the 3D printer, the risk of contamination increases. After printing, the second colonization takes place, in which the living mycelium printed into shape expands its growth and solidifies the composite material.

As soon as the desired size and shape is achieved, drying begins. Heating stops the growth process of the living mycelium in the mushroom-based composite material. This is essential so that the fungus does not change the material properties of the composite in its subsequent application and does not spread to other materials.

Preparation of the mycelium substrate (photo credits: Stavebni sporitelna Ceske sporitelny)

Applications

In order to understand the full potential of mycelium as an environmentally friendly material of the future, it is worth taking a closer look at some specific projects in the various fields of application.

Architecture

The Shape Lab of the Institute of Architecture and Media at Graz University of Technology has developed a new material, MyCera, in a research project from 2020 to 2024 by combining clay, sawdust and mycelium. “The overarching research goal is to find a practicable, long-term solution to the global problem of waste management and CO² emissions, which also affects the construction industry and the disposal of construction waste,” the research paper states. If mycelium is aligned intelligently, it could act as a fiber reinforcement for 3D-printed clay structures, according to the scientists’ approach.

They relied on the properties of mycelium to be used as a biological binder and processed the material with the Delta WASP 40100 Clay. This printer is often used for processing mycelium, as it has an open material system and can process material pastes with different compositions.

In the end, the MyCera research project was extremely successful. Although tests are still needed on the durability of the material, it has already been shown that MyCera is a promising composite material that could be used for the sustainable construction of buildings in the future. “After conducting sufficient research [we can confirm that] the proposed material composition could replace cement-based binders,” the paper concludes.

Another example of the use of mycelium in architecture is The Tree Column by London-based Blast Studio. This column structure is based on a material mixture of mycelium and waste. In fact, it consists of used cardboard, namely coffee cups and pizza boxes from the streets of London, which were shredded and mixed with water before being blended with mushroom mycelium. A robotic arm printed the paste layer by layer, creating ten modules that, when put together, form a two-meter-high column. After printing, the column continued to grow, was overgrown with edible mushrooms and only then dried to form a load-bearing architectural element.

ETH Zurich also took up the biomimetics of mycelium in a similar tree project. Together with the KIT in Karlsruhe and the ETH Center in Singapore, the institutes worked on MycoTree, a branched structure made of mycelium and bamboo that was 3D printed. The aim was to demonstrate the potential of new organic resources for the construction industry, which were manufactured using 3D printing and the calculated geometry in such a way that they achieved maximum stability.

The projects in which mycelium is used in the construction sector are numerous. These include not only buildings and walls, but also structures for underwater use. Urban Reef is a company that 3D prints reefs using ceramics on the one hand and materials such as coffee grounds and mycelium on the other.

The Tree Column (photo credits: Blast Studio)

Interior Design

The previous examples from architecture underline the fact that this vertical is experimenting with mycelium-based building materials in a variety of ways. This also applies to interior architecture and the design sector. In the furniture sector, there are already numerous projects in which mycelium is being used.

The Czech company Buřinka has a collection of sustainable designer furniture made of wood and mycelium under the name SAMOROST, the design of which is reminiscent of the natural origin of the materials. The Myco Chair by Dutch artist Eric Klarenbeek is not made of wood, but of mycelium and straw, which makes it possible to produce particularly lightweight pieces of furniture. Numerous other artists and designers also play with mycelium and natural forms. The German-Iranian architect Yasmine Mahmoudieh presented a collection of mycelium furniture as part of the Architecture Biennale 2023 in Venice.

But it’s not just furniture that is made from mushrooms in the interior design sector. MYCO ALGA are tiles for interiors that combine two biological materials in an experimental way. The bioMATTERS design studio processed algae and mushroom mycelium to produce these sustainable tiles.

Mycelium-based designer furniture from SAMOROST (photo credits: Stavebni sporitelna Ceske sporitelny)

Consumer Goods and Healthcare

However, not all projects focus on aesthetics and design. As part of the FungiFacturing project, the Fraunhofer Institutes UMSICHT and IBP investigated the insulating properties of mycelium and set themselves the goal of using this material for sound absorbers. This approach was continued in a similar research project at Fraunhofer IWU. The researchers were able to cultivate mycelium in a targeted manner, process it successfully in 3D printing and thus produce high-performance acoustic loudspeakers.

Although the projects in design, architecture and consumer goods are diverse, the use of mycelium has already proven its worth. What is more astonishing, however, is that mycelium-based materials are also used in medicine. This is mainly due to the fact that fungal mycelium has regenerative properties.

ETH Zurich and TU Delft have taken advantage of this and developed a hydrogel based in part on the shiny lacquer fungus, a local tree fungus. This gel was 3D printed into a grid and formed a robust, self-healing skin after around 20 days. The research project provided interesting findings for medical technology. However, in order to maintain the regenerative capabilities of the robotic skin, ways had to be found to feed the fungal skin.

All these projects contribute to further research into the application of mushroom mycelium and provide results on how mycelium can be processed in 3D printing in such a way that it represents a sustainable alternative for proven materials and conventional processes.

Renewable, biodegradable building blocks made from fungal mycelium (photo credits: PLP Labs)

What do you think of the 3D printing of mycelium? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Shape Lab – Institute of Architecture and Media, TU Graz