Mosquito Proboscis Repurposed as a Micro Nozzle for High Resolution 3D Printing

Most people think of mosquitoes as pests, not as tools for next-generation micro-fabrication. Yet researchers at McGill University have shown that the proboscis of a deceased female mosquito can serve as a biodegradable micro nozzle for high-resolution 3D printing. With an inner diameter of about 20 micrometers, it produces features that are finer than many commercial metal tips and at a much lower cost.

High precision nozzles are expensive and often single-use, which makes ultra-fine printing both costly and wasteful. The McGill team explored whether natural microfluidic structures could solve this challenge and found that the mosquito proboscis already has the ideal geometry. It is naturally straight, uniformly shaped and between 20 and 25 micrometers wide, making it well-suited for micro-scale extrusion.

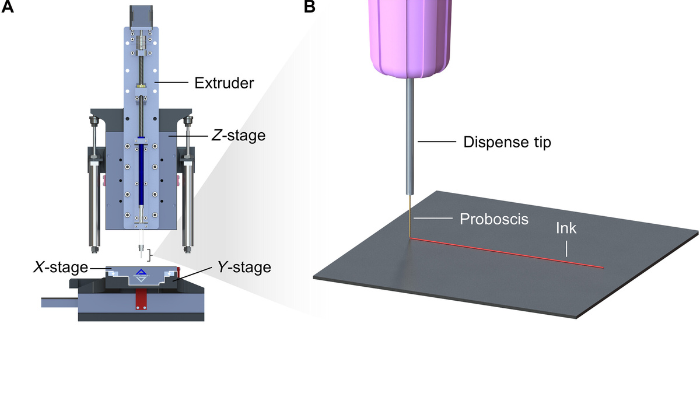

Concept and configuration of 3D necroprinting (Photo Credit: Scientific Advances)

Turning a Mosquito into a Micro Nozzle

Despite its delicate look, the proboscis is structurally strong. Tests showed it can withstand internal pressures of around 60 kilopascals, which is enough to push thick bioinks through it without rupturing. The researchers built a direct ink writing setup and attached the proboscis to a standard 30G metal tip, allowing it to connect to a syringe based extruder and move precisely over the print bed.

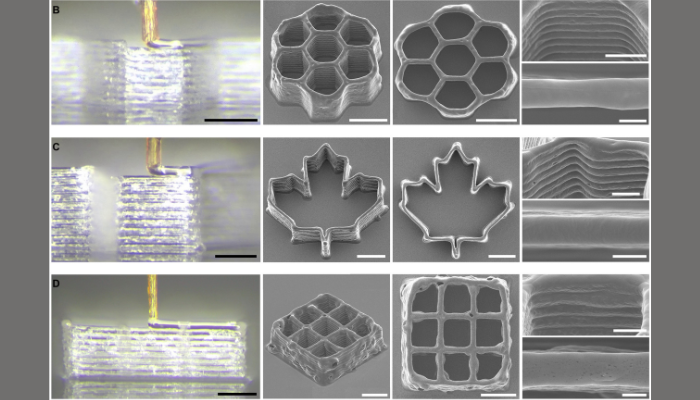

To ensure reliable printing, the team analyzed how different inks flow through the natural channel and identified the operating conditions that prevent clogging or breakage. Within these parameters, the bio nozzle performed surprisingly well. Using commercial bioinks such as Cellink Start and Pluronic F 127, the team printed honeycomb structures and three dimensional scaffolds containing B16 cancer cells. Filaments measured between 18 and 28 micrometers, and cell viability remained around 86 percent after printing.

Printed Microstructures of 3D Necroprinting. (Photo Credit: Scientific Advances)

A Sustainable Alternative for Micro-Scale Printing

Cost and sustainability are major advantages. Mosquitoes can be raised inexpensively in controlled environments and the team estimates each bio nozzle costs less than one dollar to produce. The proboscis is biodegradable and can remain functional for months when stored properly, which makes it a practical consumable for research labs. Glass pulled nozzles still achieve the very highest resolutions, but they are brittle, costly and difficult to manufacture consistently. The mosquito-based nozzle fills a different niche. It offers fine resolution, predictable performance and significantly reduced waste.

3D necroprinting is still new, but it expands how biological structures can be integrated into additive manufacturing. Instead of mimicking nature, this approach uses it directly. And in this case, a mosquito finally becomes useful.

What do you think about the mosquito proboscis being repurposed as a micro nozzle for high-resolution 3D printing? To learn more, check out the research article. Let us know in a comment below or on our LinkedIn and Facebook pages. Plus, sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel. Interested in more medical and dental 3D printing news? Visit our dedicated page HERE.

*Cover Photo Credit: Scientific Advances