MorphSensor, 3D design environment developed by MIT

Today, it is possible to 3D print a wide variety of objects from the comfort of your home: owning a desktop 3D printer allows virtually anyone to manufacture a robot dog or an anti-Covid necklace, for example. However, oftentimes, the tricky part is to add electronics to your 3D printed pieces. Researchers from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) have developed a unique 3D design environment: called MorphSensor, it enables users to digitally model not only the physical form of an object, but also its electronic function.

Embedding electronics such as sensors, chips, and tags typically means that you need to design them separately, making it difficult to create items where the added functions are integrated with the form. Can that change with the invention of MorphSensor? Lead author on a paper about the project, MIT PhD student Junyi Zhu, says: “MorphSensor fits into my long-term vision of something called ‘rapid function prototyping’, with the objective to create interactive objects where the functions are directly integrated with the form and fabricated in one go, even for non-expert users. This offers the promise that, when prototyping, the object form could follow its designated function, and the function could adapt to its physical form.”

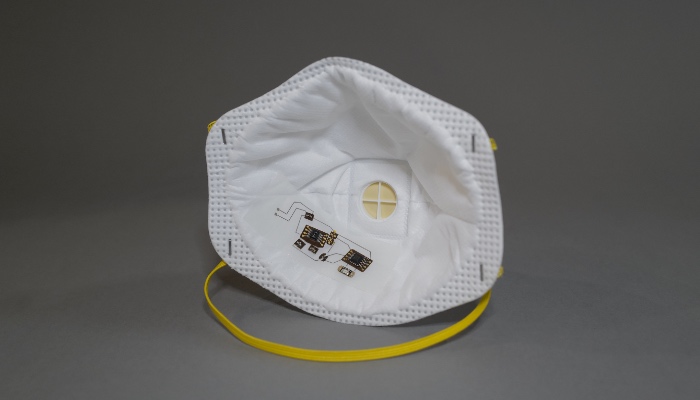

An N95 mask embedded with an electronic circuit designed in MorphSensor. (Image credits: MIT)

How does MorphSensor work?

First of all, the users of MorphSensor would need to design or import a model and sensor modules from MorphSensor’s own database or online open-sourced files. Then, the system would generate a 3D model with individual electronic components and color-coding to highlight the active components. In the next step designers can simply drag and drop the electronic components directly onto the object model, and rotate them based on design needs. Finally, users draw physical wires onto the design where they want them to appear, using the system’s guidance to connect the circuit. The designed model can be easily fabricated using an inkjet printer and conductive tape to adhere to the object.

To test the system, MIT researchers modeled a temperature-sensing ring, glasses that monitor light absorption to protect eye health, and in the context of the on-going pandemic they manipulated a N95 mask to monitor its substrate contamination, enabling it to alert its user when the mask needs to be replaced.

MorphSensor helps designers maintain connectivity of the circuit, by highlighting which components contribute to the actual sensing. However, the team hopes to expand this set of support tools even further, where future versions could potentially “merge electrical logic of multiple sensor modules together to eliminate redundant components and circuits and save space, or preserve the object’s form.”

What do you think MorphSensor? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

very much impressive all that you exposed. I wanna made an n-95 mask either you may make it on my behalf or You may give me the technique and procedure including details know how to make it by me in bulk for commercial production and purpose including materials needed for that.