Moodbytes Talks Integrating 3D Printing Into Restaurants

Food 3D printing is an emerging technology that enables chefs and restaurants to create unique, personalized dishes. It is already being used in some avant-garde and fine-dining restaurants to create intricately shaped, visually stunning dishes that would be difficult to achieve using traditional methods. In addition to their aesthetic value, food 3D printers can also offer practical benefits for the preparation and presentation of dishes. What’s more, this is an evolving technology that is set to become more accessible and affordable in the future. That’s why interesting companies and initiatives have sprung up to promote this manufacturing method in the food service sector; Moodbytes is one of them. We spoke to its CEO and founder to find out more about their use of food 3D printing.

3DN: Could you introduce yourself and tell us about your connection with 3D technologies?

My name is Marcio Barradas and I’m the CEO and founder of Moodbytes and FoodInk, one of the world’s first 3D printed food restaurants. 3D printing of food opens up a new way to bring FoodTech and FoodDesign together, using technology to develop the artistic and culinary creativity of chefs and artists themselves. Our customers came to the restaurant not only to eat, but also to experience different and delicious dishes created by renowned chefs from healthy and tasty ingredients. I’ve been using 3D technologies for 7 years, so I have a wealth of experience that I’ve shown to consumers and the food industry at the gastronomic events I’ve attended.

Marcio Barradas

3DN: What is Moodbytes, and how did the idea for the company come about?

Moodbytes is a company dedicated to innovation in the world of gastronomy, researching, developing and implementing the latest trends and technologies related to the world of food, striving to improve all processes, from cultivation to consumption, creating a more sustainable and intelligent future for gastronomy. We use an innovative methodology that enables us to combine modern technologies with personal care and food.

At the same time, it helps us to support and motivate improved health, pleasure and personalization. It all started with Foodink, the first company to manufacture 3D-printed meals using the latest technologies in 2015. It had a global media impact as we had over 35 million views, publications in over 75 renowned media and over 3,000 people on the waiting list for Food Ink meals. Subsequently, in 2017, Moodbytes started up as a company after all the experience of FoodInk as a representative image of innovation in gastronomy around the world.

3DN: How are you using food 3D printing, and can you tell us more about Moodbytes’ latest projects?

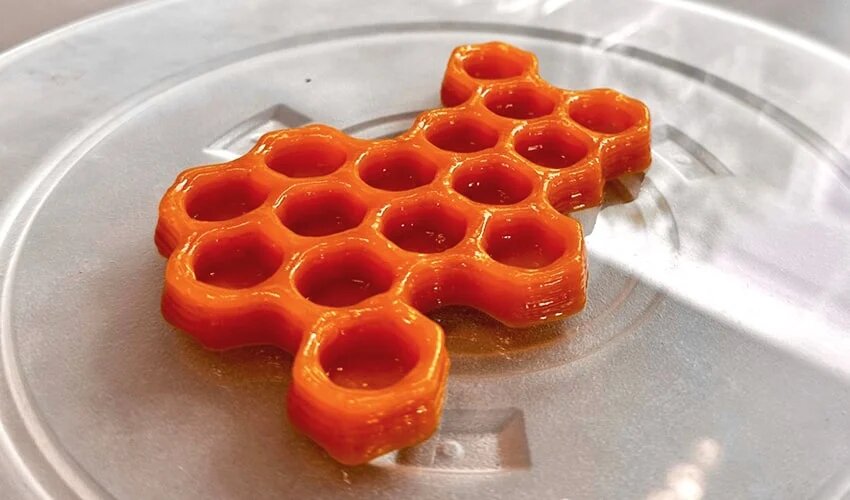

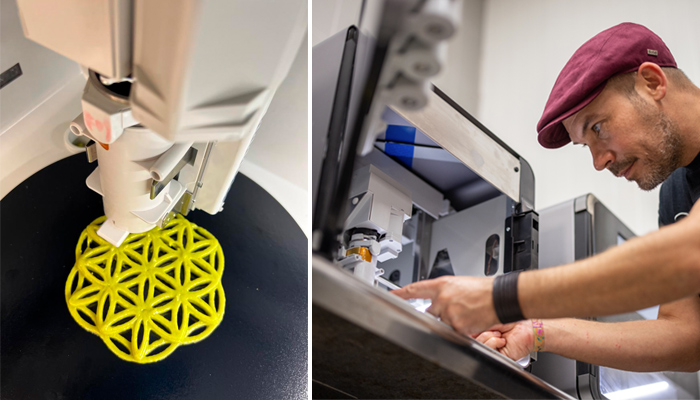

We use Foodini, a food 3D printer that promotes cooking with fresh, real ingredients. Foodini is the first 3D printer that prints all kinds of food, from savory to sweet, using real, fresh ingredients. Foodini comes complete with empty stainless steel food capsules, and expands the creative possibilities for chefs by quickly transforming new ideas into unique, surprising and delicious dishes that are then easy to repeat for multiple guests. Thanks to a food DNA test, we are able to obtain the consumers’ genetic map, enabling us to know which foods suit them best, and thus to design the modern meal. It also allows us to tailor food to what is most beneficial for us.

3D printers simplify all the difficult processes that require more time and investment in the chocolate-making process, design, trial and error and so on. We can imagine any type of chocolate (90-75-45% cocoa, milk, white, etc.) and print it at home or in the office. Today, we can offer you automated repetition processes in the kitchen, so that you can copy the same recipe as many times as you like, and even prepare the same dish with different ingredients. Our partner in this process is Natural Machines, a company that makes 3D printers and has enabled us to create some amazing meals with our freeze-dried powders. We took part in a few food events during this year, 2023, including WEP in KAUST and Dare2Change in Porto, where we showed all participants how using 3D printing technology can be a recycling option for food waste.

Moodbytes is working to further spread food 3D printing

3DN: What are the advantages of this method over traditional cooking? Are there any limitations?

The benefits of food 3D printing are quickly becoming apparent for haute cuisine, as it enables experimentation with shapes and flavors and differentiation from the competition. The food customization offered by 3D printing can prove invaluable to all sectors. Chefs such as Paco Pérez, Paco Morales, Davide Oldani, Sergi and David Torres have already implemented these technologies in their Michelin-starred restaurants. Thanks to 3D printing, we can tailor food to our tastes. We can also know what we’re eating and make sure it’s balanced and has no side effects.

Thanks to 3D printers, we can also choose exactly what we want to ingest into our bodies, using the ingredients we like. We now have the ability to store, concentrate and preserve food in a new, safer, more sustainable and personalized way. We can deliver essential nutrients to every person, in the healthiest way possible. Moodbytes offers a new experience in the way people relate to food. When it comes to babies, we can offer parents the ability to print purées of any flavor, creating the textures their children prefer. In this way, you can enjoy a personalized, healthy diet.

This method has two limitations: economics and energy. For the 3D printing machine to work, it has to be permanently plugged in. That’s why we’re still working on environmentally-friendly energy solutions. What’s more, it’s an expensive technology.

3DN: How do you see the future of additive manufacturing in the culinary field?

Right now, we’re striving to find products that are somehow natural rather than processed, so that we can replace what has been created so far with something natural that has at least the same properties, the end result being more or less the same in terms of texture, technological characteristics. And this has advantages, or at least no negative impact on our health.

A closer look at food 3D printing

3DN: Any last words for our readers?

At Moodbytes, we believe that by using 3D printing technology, we can create a more sustainable and personalized approach to food production and consumption. We are committed to continuing our research and development work in this area, and hope to inspire others to join us on this journey towards a healthier, more sustainable and more delicious future. We thank you for your interest in our work and hope to see you soon at one of our events. To find out more, click HERE.

What do you think of Moodbytes and its use of food 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Moodbytes