An intelligent production module to 3D print parts on site

Can you imagine a parts factory inside a container? The so-called Mobile Smart Factory is a practical solution to bring the production process with 3D printing closer to anyone, anywhere. It is a factory inside modular containers equipped with devices that provide flexible and secure production capabilities on site. Essentially, it allows a fast and cost-effective supply of metal and plastic parts where needed. In addition, it covers all steps of additive manufacturing, including pre- and post-processing.

As we know, additive manufacturing is seen as a promising way to optimize the production of end-use and spare parts. It allows reducing inventory levels and production costs by printing on demand. Despite the many benefits of 3D printing, the adoption of the technology is still limited, as it is often not easy to handle and can represent a costly investment. With this idea in mind, the Mobile Smart Factory could provide a solution to these challenges. The company behind the idea, which bears the same name as the module itself, aims to pave the way towards 3D printing of independent, cost-effective and reliable parts.

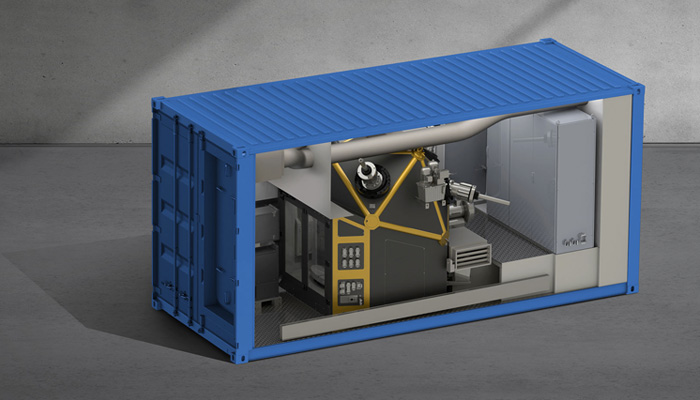

The 3D printing module for spare parts | Credits: Mobile Smart Factory

Mobile Smart Factory: standard containers to produce unique solutions

For companies working on the high seas, this transportable factory can speed up production and manage supply chain problems more effectively by adding flexibility. But what does the Mobile Smart Factory consist of? The technology needed to manufacture the spare parts is inside two containers. The control unit is housed in the first one, which is 6 meters long and weighs about 12 tons. It is used for pre-processing and consists of a workstation with a computer, an industrial 3D printer for polymers, a 3D scanning system and a storage area.

In the second container, 12 meters long and 15 tons in weight, is the parts production unit. It integrates a multi-optional 6-axis machining center from the company METROM, which comments: “Based on a patented parallel kinematics concept, the machine combines an additive arc-wire manufacturing module (WAAM) with a milling and drilling unit“. The welding and machining process runs as an NC program based on pre-qualified parameters. The main spindle of the machine is centrally positioned, allowing the machining of large workpieces.

Parts manufacturing is a critical and challenging process for a profitable business operation. In fact, it can lead to various problems, such as uncertain and volatile demand, or high customer expectations. The Mobile Smart Factory 3D printing module could be an effective solution to this issue. You can find more information HERE. What do you think of this production module? Let us know in a comment below or on our Facebook and Twitter pages! And remember to sign up for our free weekly Newsletter, to get all the latest news on progress, research and more entrepreneurs in 3D printing send straight to your inbox!