MIT Researchers Use 3D Printing to Create a Self-Heating Microfluidic Device

You don’t have to be an engineer with extensive technical knowledge to come into contact with microfluidics and their applications. The aim of microfluidic systems is to control small quantities of liquids in tiny networks and channels, and to discuss and analyze their effects. Furthermore, microfluidic components are used in a wide range of applications, for example in medical technology, biotechnology, process and sensor technology and also in consumer goods. For example, microfluidics are used to detect diseases in blood and fluid samples. A prominent example from the recent past, which we have probably all experienced at one time or another, is do-it-yourself Covid-19 tests.

However, the challenge with microfluidic applications is that some chemical reactions only take place at certain temperatures and thus require more complex microfluidic devices. These are often manufactured in clean rooms and contain heating elements made of gold and platinum. The manufacturing process is therefore expensive, complicated and difficult to scale up. This is where a research project at MIT (Massachusetts Institute for Technology) comes in, where scientists have been working on the development of a 3D-printed, self-heating microfluidic device, as announced in a press release yesterday.

Covid self-tests are a prominent example of microfluidic applications (photo credits: Pixabay)

The research group, led by principal scientist in MIT’s Microsystems Technology Laboratories (MTL) Luis Fernando Velásquez-García, used 3D printing to produce a self-heating microfluidic device that can transport liquids and trigger chemical reactions. The mini-reactor can analyze substances and detect diseases. As the device was produced in a single print run, it offers forward-looking prospects for the cost-effective production of precise measuring instruments for the early detection of diseases. This is particularly interesting for developing countries, where there is often no optimal laboratory environment.

“Clean rooms in particular, where you would usually make these devices, are incredibly expensive to build and to run. But we can make very capable self-heating microfluidic devices using additive manufacturing, and they can be made a lot faster and cheaper than with these traditional methods. This is really a way to democratize this technology,” emphasized Velásquez-García, because the microfluidic mini device produced costs only about 2 US dollars thanks to 3D printing.

Making Microfluidic Devices With Multi-Material 3D Printing

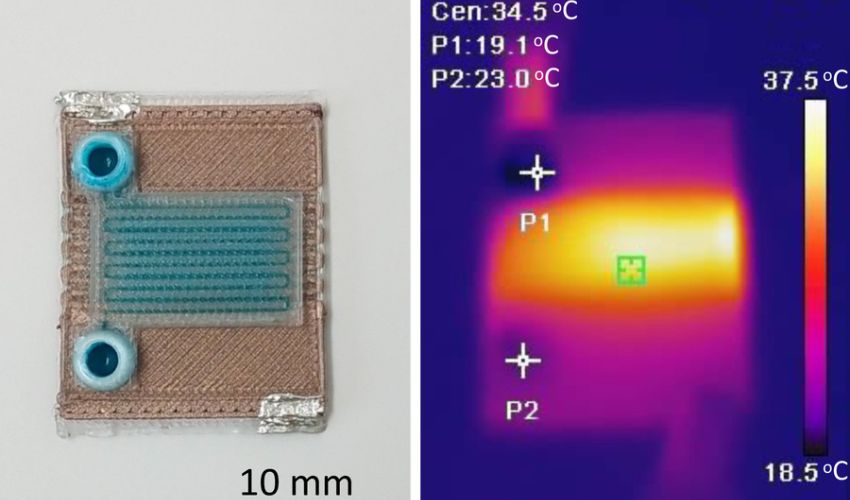

The microfluidic device was manufactured in what the research team deems a monolithic process, i.e. it was done in one step on the printer without the need for any post-assembly. Using multi-material printing, the researchers produced the device with the built-in heating elements in a single manufacturing process. Different materials were extruded through different nozzles to create the complete mini-reactor layer by layer. This is able to heat the liquid in the channels to a specific temperature as it flows through the channels. Heating can also be restricted to a specific area of the device. The technology allows for various customization options so that preset heating profiles can also be implemented.

For example, in the first created prototype, it was possible to heat the liquid by 4°C as it flowed through the channels from the inlet to the outlet. This application test shows the further possibilities of device production, where liquids can flow in certain patterns or along predefined lines and enable chemical reactions. The first device produced by the researchers has microfluidic channels that are only about 500 micrometers wide and 400 micrometers high.

As the device contains integrated heating elements, it was necessary to use a conductive material. For this reason, several materials with different properties were required, which is where multi-material printing came into play. The researchers used biodegradable PLA and a modified version of PLA, namely a PLA enriched with copper nanoparticles. The otherwise insulating material was thus used as an electrical conductor and for the pressure of the heating resistor. “You can use these two materials to create chemical reactors that do exactly what you want. We can set up a particular heating profile while still having all the capabilities of the microfluidic,” said Vlásquez-García on the use of the PLA variants.

By adding electricity to the heating resistor, the energy was converted into heat. This then heats the liquid that flows through the channels of the microfluidic device, which was also set up in the same printing process. However, in order for the heat to be transferred from the heating resistor to the liquid, it was necessary to print a thin PLA wall. This had to be thin enough not to retain the heat, but thick enough to repel the liquid. In order to be able to observe the chemical reactions and draw conclusions about the processes, it was therefore necessary for the researchers to use transparent PLA so that they could observe the liquids in the device.

PLA is obtained from corn starch and is actually insulating. By enriching it with copper nanoparticles, it becomes electrically conductive.

What Were the Challenges?

By using similar materials, the researchers were able to maintain almost the same printing temperature during 3D printing, which was a clear advantage during the printing process itself. But, there are also some limitations when using PLA, because although PLA can withstand temperatures of up to 50 degrees, it gradually decomposes at higher temperatures. However, some chemical reactions only occur at higher temperatures. In a PCR test, this is around 90°C. In order to precisely control the temperature in the microfluidic device and enable accurate measurement, an additional material would therefore have to be used to counteract the limits of PLA.

Velázquez-García’s research group had magnets in mind, as these enable chemical reactions and simultaneously sort and arrange the particles. The researchers are also experimenting with other materials and want to explore the electrical conductivity of PLA in more detail and analyze the material in greater depth. “It is amazing when you think about it because the PLA material is a dielectric, but when you put in these nanoparticle impurities, it completely changes the physical properties. This is something we don’t fully understand yet, but it happens and it is repeatable,” commented Velázquez-García, before adding, “If we can understand the mechanism that is related to the electrical conductivity of PLA, that would greatly enhance the capability of these devices, but it is going to be a lot harder to solve than some other engineering problems.

Although the team still faces some challenges, the results of the study are very promising. There are exciting potential applications for biological samples, the mixing of liquids and implants such as chips that dissolve. As mentioned at the beginning, developing countries in particular could benefit from low-cost chips with microfluidic channels and electrical features, as the one-step process reduces costs and the need for laboratory equipment.

Internationally, the MIT project has been well received and there has already been positive feedback from the Royal Institute of Technology in Sweden and Keio University in Tokyo, both emphasizing the future potential of 3D printed microfluidic devices and discussing possible new applications. You can find more information HERE.

What do you think of this 3D-printed, self-heating microfluidic device from MIT? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: MIT