MIT researchers create 3D printed soft brain implants

At MIT, a team of researchers is currently working on 3D printing neural implants as soft and flexible as rubber. Traditionally, brain implants are made of metal – this new method would allow for the brain implant to better adapt to the contours of our brain, thus avoiding inflammation and the accumulation of scar tissue. At the moment, the team is still in the testing phase. It has already implanted the 3D printed neural device made from a conductive polymer in a mouse, and has been able to obtain a precise image of the brain’s activity.

More generally, in the medical sector, and more particularly in dentistry, additive manufacturing is helping to design tailor-made implants that are better adapted to the morphology of each patient. But it can also be used throughout the research and development phase, to understand complex structures and facilitate the deployment of solutions. When it comes to the study of the brain, for example, one of the most complex vital organs, 3D printing can help design devices for study, testing, monitoring, etc. The team of Xuanhe Zhao, a professor of mechanical engineering and of civil and environmental engineering at MIT, has therefore used 3D printing technologies to develop flexible brain implants capable of monitoring the organ’s activity over long periods of time without aggravating the surrounding tissue.

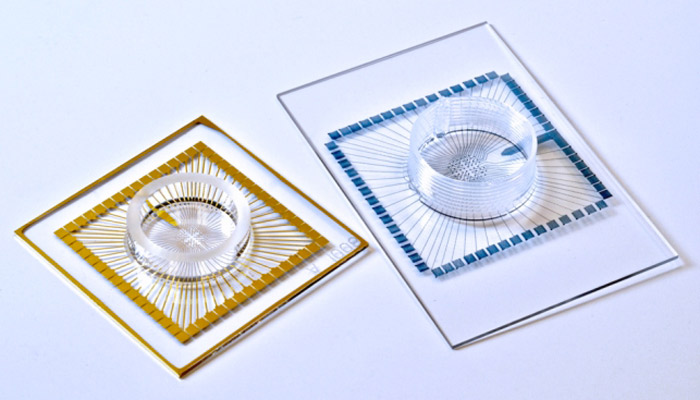

3D printing of the electrode | Credits: MIT

The use of polymer 3D printing

Based on the finding that metal electrodes and implants were not suitable in the long run, the researchers opted for a polymer that had to be conductive. Today, most of the conductive polymer solutions available on the market are used as antistatic coatings, i.e. in liquid form. Hyunwoo Yuk, a graduate student in the Zhao group at MIT, adds: “The liquid form is mostly for homogenous coatings, and it’s difficult to use this for any two-dimensional, high-resolution patterning. In 3D, it’s impossible.” Researchers therefore had to develop another form, a kind of hydrogel.

The polymer used is a PEDOT:PSS which is a conductive material usually supplied in the form of a dark blue liquid ink. The team explains that they freeze-dried this material, removing the liquid to obtain a dry matrix of conductive nanofibres. These break on their own, so have been mixed with a hydrogel made of water and organic solvent. According to the team, 5-8% nanofibres were added to make a paste similar to toothpaste. This thickness made it possible to extrude and create the desired 3D printed devices.

A 3D printed neural device

To test their material, the MIT team 3D printed a small rubbery electrode, no larger than a piece of confetti. It consists of a layer of flexible, transparent polymer on which the researchers extruded the conductive polymer in thin parallel lines. They all converge at a single point, small enough to capture the electrical signals of a single neuron (about 10 microns wide). This electrode was then implanted in the brain of a mouse: the team was able to successfully capture one of its neurons and thus monitor its brain activity. Professor Zhao explains: “Traditionally, electrodes are rigid metal wires, and once vibrations occur, these metal electrodes could damage tissue. We’ve shown that you can now insert a gel probe instead of a needle. In addition, the sensitivity of this electrode is higher.“

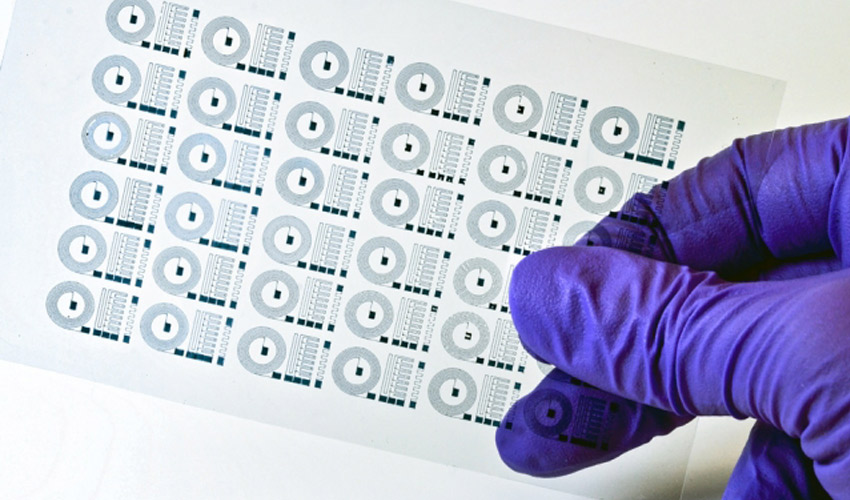

Researchers also designed a multi-electrode array | Credits: MIT

In addition to the neural probe, the team also made a multi-electrode array – a small plastic square the size of a post-it, printed with very thin electrodes. All of these tests could be useful in tailoring long-term brain therapies and implants for a variety of neurological disorders. In any case, this is a promising application case for the study of the brain! You can find more information HERE.

What do you think of this team’s research? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!