MIT & ETH Zurich Demonstrate Soft Robotics Potential With 3D Printed Robotic Hand

The research and development of robotics is growing in line with its respective areas of application and requirements. In particular, soft robotics is on the rise as robots made of soft materials enable elastic deformations and minimize hazards that often exist with conventional robots made of rigid materials such as steel or aluminum. The advantages of soft robotics are in demand in a wide variety of fields such as healthcare, where human-machine interactions and gripping fragile or complex objects is being tested.

Growth driven by new applications is also a parameter that applies to the development of 3D printing. Robotics and additive manufacturing share this commonality so it is no wonder that the technologies are merging and robots are increasingly being manufactured using 3D printing. Until now, additive manufacturing has been limited to processing only quick-curing plastics. However, an advanced, expanding portfolio of compatible materials is also bringing new developments and new application potential. In this context, a study by the Massachusets Institute of Technology (MIT) and ETH Zurich in Switzerland, focused on a special role for a 3D-printed robotic hand.

For the first time, researchers across the Atlantic have succeeded in processing slow-curing plastics in 3D printing. These plastics are elastic, more durable, and enable a handheld robot to print them in a single pass. This was made possible by the cooperation with the US start-up Inkbit and its technology. They worked together on the study “Vision-controlled jetting for composite systems and robots” with the aim of producing high-resolution, complex structures with different material properties and recreating the functions of natural organisms in a synthetic form. They combined 3D printing with laser scanners and a feedback mechanism.

This approach made it possible to 3D print low-viscosity, slow-curing polymers with excellent elasticity. In this way, complex, resistant materials used for robots can now be produced, which consist of different, high-quality materials and have a combination of elastic and rigid structures. The successful continuous printing of filigree parts and human-like structures with cavities also opens up new possibilities in soft robotics. The results of the study were published earlier this month in Nature.

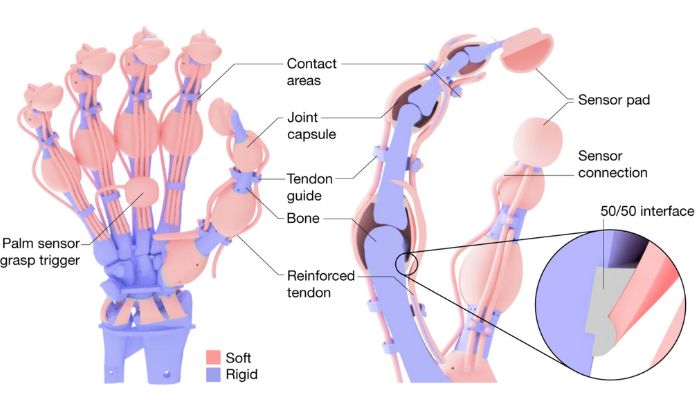

The study shows new possibilities for soft robotics and 3D printing. (Image: Thomas Buchner et al.; Nature)

As part of the study, ETH Zurich and Inkbit tested their approach in various application examples. They produced a wide range of high-resolution composites and various robots, including robotic hands, pneumatically operated walking manipulators, heart pumps and other metamaterial structures. One example of a robotic hand with artificial bones and ligaments stands out, as the hand is made of different polymers and has cavities to house the sensors. It was printed in a single session and no further assembly was required. One of the reasons for this was the polymers used.

“We would not have been able to produce this hand with the fast-curing polyacrylates that we used to use in 3D printing,” explains Thomas Buchner, PhD student in the group of ETH robotics and first author of the study. “We are now using slow-curing thiol-ene polymers. These have very good elastic properties and return to their original state much faster than polyacrylates after bending.”

These properties also make thiol-ene polymers ideal for producing the elastic bands of the robotic hand. In addition, the stiffness of thiols can be very finely adjusted and thus adapted to the requirements of soft robots. “Robots made of soft materials such as the hand we have developed have advantages over conventional robots made of metal: because they are soft, the risk of injury is reduced when they work together with humans, and they are better suited to handling fragile goods,” explains ETH Professor Robert Katzschmann.

A New Technological Approach for 3D Printing

The approach that MIT, ETH and Inkbit took with the robotic hand also offers high throughput and an automated multi-material printing process with high scalability. The aforementioned slow-curing polymers (thiolenes and epoxides) played a key role in the creation of the robotic hand. However, being able to process these using 3D printing also depends on the technology used. Until now, only fast-curing polymers could be processed in 3D printing, as a device scrapes off unevenness after curing and thus ensures parts of the appropriate quality. However, slow-curing polymers would cause such a scraping device to stick, so it is worth taking a closer look at the technology used by ETH Zurich in its research.

The 3D-printed robotic hand consists of artificial bones, tendons and ligaments made of different materials, including soft, elastic plastics. (Image: Thomas Buchner et al; Nature)

This is the benefit of Vision Controlled Jetting technology from the US start-up Inkbit, a spin-off from MIT. With this printing technology, an inkjet process, nozzles apply the desired viscous material at each point, which is cured layer by layer by a UV lamp. What is special about the technology, however, is that a 3D laser scanner then checks the printed layer for unevenness, which is then taken into account when the next layer is applied.

“A feedback mechanism compensates for these irregularities when printing the next layer by calculating the precise adjustments to the amount of material to be printed in real time,” explains Wojciech Matusik, professor at MIT and co-author of the study. This means that the scanning system captures the 3D structure and enables immediate adaptation via a digital feedback loop. This eliminates the need for additional mechanical solutions and facilitates a non-contact process in which continuously curing plastics with different elasticities can be printed. Wax is used as a support structure, which is then melted away at 60 degrees celsius.

One challenge faced by the team in this research project was that some printed parts were deformed in the open air. In addition, the interfaces (surface layers) of the multi-material prints did not always adhere well, although the researchers hope this can be improved in the future. The overall high resolution, fast printing process and wide range of materials with different properties can already enable a variety of hybrid, soft/rigid robots and other applications. MIT and ETH Zurich have been able to optimize Inkbit’s printing technology for the use of slow-curing polymers through testing various applications and will now focus on exploring further possibilities and trying out printing and testing even more complex structures. Inkbit’s eventual goal is to develop and bring the technology to the market. You can find out more about the study HERE.

What do you think of the 3D-printed robotic hand and the research work between MIT and ETH Zurich? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover photo credits: ETH Zürich, Thomas Buchner