MIT Develops 3D Printing Technique for Objects with Varied Colors & Textures

Multi-material printing technology has already been discussed at 3Dnatives. This process makes it possible to manufacture 3D objects using several materials in a single continuous print. It opens up a way to create tailor-made devices in a variety of colors and textures. However, this method has its limitations. The process can be slow and costly, as current 3D printers often have to alternate between different nozzles, removing one material before applying another.

In response to this problem, researchers at MIT and the Technical University of Delft in the Netherlands have developed a more efficient method, offering both greater precision and reduced waste. The technique uses heat-reactive materials to enable objects with different colors, shades and textures to be printed in a single printing phase.

A New Approach to Customizing Textures and Colors

The researchers call their method “speed-modulated ironing.” This method can be used for FDM 3D printing and involves a 3D printer with two nozzles. The first deposits a heat-reactive filament, while the second then passes over the printed material to trigger various effects, such as changes in opacity or texture, through the targeted application of heat. By adjusting the speed of this second nozzle, they can modulate the temperature precisely, influencing the color, nuances and roughness of the filament.

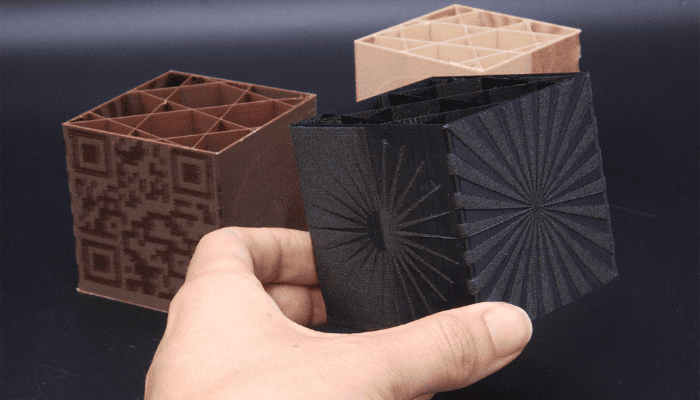

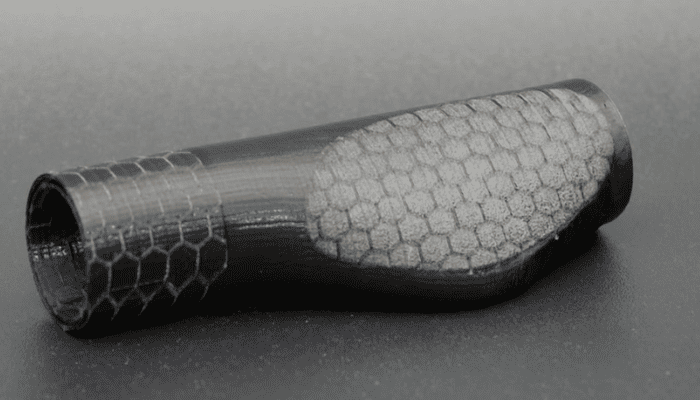

This method paves the way for the creation of artistic visual effects by varying the colors of printed objects, while at the same time making it possible to produce textured surfaces. “Today, we have desktop printers that use a smart combination of a few inks to generate a range of shades and textures. We want to be able to do the same thing with a 3D printer — use a limited set of materials to create a much more diverse set of characteristics for 3D-printed objects,” explains Mustafa Doga Dogan, co-author of an article on the “speed-modulated ironing” method.

A New 3D Printing Technique for Heat Control

Although the use of heat-sensitive filaments is promising, most current techniques rely on a single nozzle to perform both printing and heating. In this system, the 3D printer must first heat the nozzle to the desired temperature before starting to deposit the material. This heating and cooling process is time-consuming and carries the risk of filament degradation when temperatures are too high. To overcome these difficulties, the team’s approach is to print with a first nozzle, then activate a second empty nozzle whose sole role is to provide heat.

Instead of having to adjust the temperature to activate the material reaction, this method maintains a constant temperature on the second nozzle while varying its travel speed over the already-printed material. By modifying this speed, it is possible to achieve different temperatures at the printed layer. “It is similar to what happens if you move your finger over a flame. If you move it quickly, you might not be burned, but if you drag it across the flame slowly, your finger will reach a higher temperature,” explains MIT researcher Marwa AlAlwi. The model links a material’s temperature to its reaction to heat to determine the ideal nozzle speed to achieve specific colors, shades or textures for each printed object. “There are a lot of inputs that can affect the results we get. We are modeling something that is very complicated, but we also want to make sure the results are fine-grained,” says AlAlawi.

A Faster Production Than Traditional Methods

The researchers evaluated their method using three types of heat-reactive filaments. The first is a foaming polymer whose particles expand with heat, enabling the creation of various shades, transparencies and textures. They also tested a filament containing wood fibers and another with cork fibers, both of which can be carbonized to produce darker shades. The researchers demonstrated that their technique can be used to manufacture objects such as partially translucent water bottles. Using this example, they used the foaming polymer at low speed to create opaque areas, and at high speed to obtain translucent areas. Creating similar objects with conventional multi-material 3D printing methods takes much longer, sometimes even several hours, while using more energy and materials.

What do you think of MIT’s new 3D printing technique? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: MIT