MIT Uses Artificial Intelligence To Automate 3D Printing Materials Discovery Process

Artificial Intelligence, and more specifically, machine learning, is finding its way through various applications in the additive manufacturing industry. This time, researchers from MIT have applied the data-driven nature of machine learning to automate the process of discovering new 3D printing materials. With machine learning, material performance factors such as toughness and compression strength were optimized using an algorithm that quickly outperformed conventional methods of 3D printing material formulation. As a result of this study, the researchers created a free, open-source materials optimization platform called AutoOED, allowing other researchers to conduct their own material optimization.

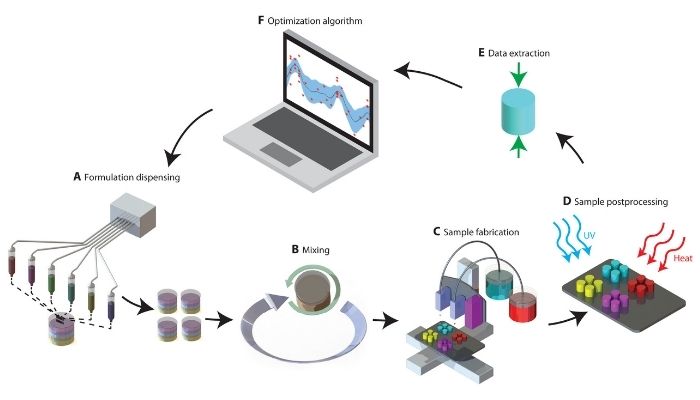

The algorithm was able to suggest novel chemical formulations that a human likely may not have considered. “Materials development is still very much a manual process. A chemist goes into a lab, mixes ingredients by hand, makes samples, tests them, and comes to a final formulation. But rather than having a chemist who can only do a couple of iterations over a span of days, our system can do hundreds of iterations over the same time span,” explained Mike Foshey, co-lead author of the paper and mechanical engineer and project manager in the Computational Design and Fabrication Group (CDFG) of the Computer Science and Artificial Intelligence Laboratory (CSAIL).

3D Printing Materials

Six chemicals were identified to use in the formulations then the algorithm’s objective was set to uncover the best-performing material, controlled for toughness, stiffness, and strength. In terms of automating the materials discovery process, using this methodology from MIT, the dispensing, mixing, 3D printing, post-processing, and testing steps can be completed without human input. However, manual labor would be needed to transfer materials between the different steps in the sample fabrication pipeline — though, Foshey believes robots could be incorporated to eliminate human labor in future versions of this system. After testing 120 formulations, the study resulted in 12 optimized formulations — with the researchers concluding that their research methodology could be generalized for application to other material design systems, enabling automated discovery in other materialssciences.

The aforementioned AutoOED platform incorporates the optimization algorithm from this study and is currently available as a software package. This study was supported by the German company BASF, the largest chemical producer in the world. You can learn more about this 3D printing materials study HERE.

Photo Credit: ThisisEngineering / Unsplash

What do you think of this MIT’s use of artificial intelligence? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.