MIT 3D Prints Water Filters Inspired by Manta Rays

Biology has long been a source of design inspiration—think of Leonardo da Vinci’s flying machine, a contraption with wings inspired by bats. Today, engineers continue the practice, often integrating models inspired by nature into 3D printed designs. In a new project, the Massachusetts Institute of Technology (MIT) 3D printed water filters inspired by manta rays. By deriving design principles from the rays, which go beyond traditional filtration systems, the team created manta ray-inspired water filtration devices.

Manta rays are filter-feeders, which means they strain their food from mouthfuls of seawater. MIT engineers realized that one family of manta rays in particular—the mobula ray—filters its food in a way that could be adopted in industrial water filters. These aquatic creatures swim with their mouths open through plankton-rich regions of the ocean, catching plankton in their gullets while water streams into their mouths and out through their gills.

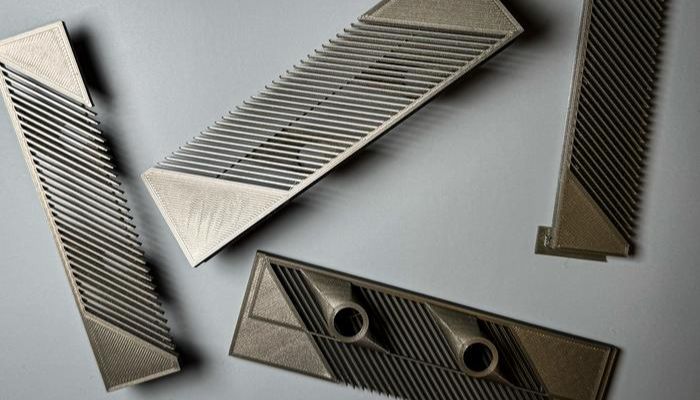

MIT’s 3D printed filtration devices inspired by mobula rays (Photo credits: Jennifer Chu, MIT)

So what stops plankton from flowing out of the manta’s mouth through the gills? The mobula ray’s mouth is lined on either side with comb-like structures called plates that draw water into the ray’s gills. The MIT team believes that due to the dimension of these plates, incoming plankton may bounce off of them, flowing deeper into the manta’s cavity. The gills also absorb oxygen from the outflowing water, allowing the ray to breathe while feeding. One of the authors of the study, Anette “Peko” Hosoi, explained, “We show that the mobula ray has evolved the geometry of these plates to be the perfect size to balance feeding and breathing.”

Similarly, industrial filters must balance permeability (how easily fluid can flow through a filter) and selectivity (how successful a filter is at keeping out particles of a certain size). The qualities are often correlated: if a membrane, for instance, has large holes that let a lot of water through, it will be more permeable and less selective. Inversely, if a membrane has small holes that let less water through, it will be less permeable and more selective.

Because industrial cross-flow filters function similarly to the mobula ray’s filtration system, industrial filters could be optimized with the manta ray’s filters in mind. “We want to expand the design space of traditional cross-flow filtration with new knowledge from the manta ray,” lead author and MIT postdoc Xinyu Mao PhD said. “People can choose a parameter regime of the mobula ray so they could potentially improve overall filter performance.”

What Makes the Mobula Ray’s Filter-Feeding System Effective?

The authors of the study called the ray’s ability to breathe and feed simultaneously “an elegant balance,” and there is one key element that makes it so: vortices. For part of their project, the team created a device for water to flow through and at one end, they placed a 3D printed structure that resembled the grooved plates on the floor of the mobula’s mouth.

Then, the researchers pumped water through the channel at various rates, along with colored dye so they could see the flow. They discovered that when they pumped the water slowly it went smoothly through the 3D printed filter. However, when they increased the pumping speed, the water did not flow through easily. Instead, it appeared to swirl at the mouth of each of the filter’s grooves, creating a vortex.

“This vortex is not blocking water, but it is blocking particles,” Hosoi explains. “Whereas in a slower flow, particles go through the filter with the water, at higher flow rates, particles try to get through the filter but are blocked by this vortex and are shot down the channel instead. The vortex is helpful because it prevents particles from flowing out.”

These vortices are critical for the mobula rays filter-feeding. By swimming at just the right speed, the rays can form vortices between the grooved plates that effectively block plankton particles from leaving their mouth—even plankton particles that are smaller than the space between plates.

Implementing the Design in Water Filters

Now, using the mobula ray model, industrial cross-flow filters can be improved. With the experiment results and dimensions of mobula ray filtering features, the MIT team created a design plan for cross-flow filtration. Mao explained, “We have provided practical guidance on how to actually filter as the mobula ray does.”

While we don’t know what type of 3D printing technology the researchers used for the project, we know that they would have benefited from the on-demand, customizable aspect of the technology. With this research, manufacturers could recreate industrial filters using these principles, perhaps with 3D printers. “Our guidelines tell you: If you want your plant to pump at a certain rate, then your filter has to have a particular pore diameter and spacing to generate vortices that will filter out particles of this size,” Hosoi said. “The mobula ray is giving us a really nice rule of thumb for rational design.” To learn more, read MIT’s press release here.

What do you think of MIT’s mobula ray-inspired, 3D printed filtration plans? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.