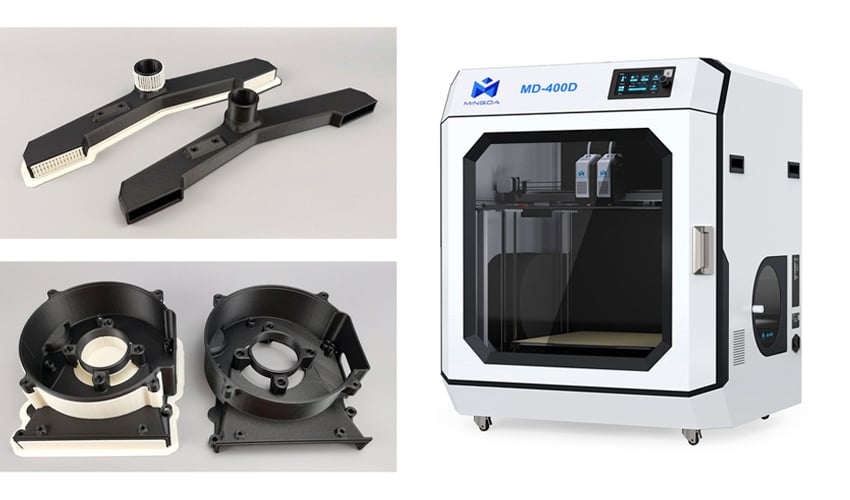

MINGDA 3D Is Paving the Way for Larger-Scale IDEX Printing With the MD-400D 3D Printer

One of the terms that we have increasingly heard in the 3D printing field is IDEX. Meaning independent dual extruders, the technique allows for two print heads to move independently of each other. Each has a nozzle and can print with either the same or different materials allowing for much faster FDM printing as well as the creation of complex geometries with overhangs or support structures that can be easily removed after printing. However, one drawback is that many IDEX solutions are not able to have a larger print volume. Luckily that does not need to be the case. MINGDA 3D has launched its latest 3D printer, the MD-400D, which is notable not just for its own IDEX system with different functions, but also for its size.

As mentioned, though IDEX printers are gaining in popularity, many have a printing volume of around 200-300 mm while the MD-400D has a build volume of 400x400x400 mm in free mode, larger than many of the other solutions on the market. But of course that is not all. MINGDA itself is a Chinese company that since 2012 has sought to provide large-scale industrial 3D printing solutions to the world. The MD-400D is a continuation of that goal. One product manager at MINGDA 3D expands, “We are thrilled to introduce the MD-400D to the 3D printing community. This printer represents our commitment to pushing the boundaries of innovation and providing our customers with the tools they need to bring their ideas to life. With its advanced features and exceptional performance, the MD-400D will set a new standard in IDEX 3D printing technology.” We took a closer look at what you can expect from the machine.

The MINGDA MD-400D 3D printer

The Features of MINGDA MD-400D 3D Printer

With the MD-400D, MINGDA 3D has created an IDEX 3D printer that can truly be considered to be industrial-grade thanks to its large-scale and high-temperature 3D printing. According to the manufacturer, this makes it the idea choice for a variety of needs notably two-color, two-material and mass production additive manufacturing. And that has been facilitated by the inclusion of a number of interesting characteristics.

First, through the IDEX system itself, MINGDA has opened up the possibility for a number of different modes. Users will have access to duplicate mode, mirror mode, support mode and dual-color mode. You may have heard of some of these before, they are abilities that are only possible through true IDEX printing, such as with the MD-400D. Duplicate mode and mirror mode especially are known for their ability to increase production. Duplicate mode allows a user to print two of the exact same part at the same time while mirror mode does the same though with the parts printed symmetrically, such as with a reflection in a mirror. Support mode meanwhile allows for users to print materials and supports simultaneously enabling the creation of complex geometries as well as hollow structures. Finally, dual-color mode allows for printing two separate colors at once in one model. These different modes allow for flexibility for the user when it comes to benefiting from the IDEX system.

The different modes available on the MINGDA MD-400D 3D printer (duplicate, mirror, dual-color and support)

Furthermore, in order to provide a solution that is industrial, MINGDA 3D also has focused on a few other notable features beyond the size. For example, the auto-leveling functionality which allows for automatic adjustment of the print bed. A necessity for those wishing to avoid print failures while saving time and effort by eliminating the need for manual calibration. The extruders are also interesting. Users have the possibility of replacing the common hot ends with high-temperature ones which reach 350℃, allowing for a wider range of materials including PET-CF, Nylon-CF, nylon glass fiber, ABS-CF and more. These are easy to swap and open up more applications with the 3D printer. Meanwhile, the common end is compatible with PLA, ABS, TPU, PETG and other common 3D printing filaments. The dual-gear direct extruder is also worthy of note as it is more conducive for printing flexible filament and feeding more smoothly.

Last but not least, the MD-400D has a fully metal enclosed structure for better printing with engineering filaments like ABS, reducing issues like shrinkage and warping. These issues are also addressed by the PEI build plate which also facilitates easier removal of parts. It also has a built-in air filtration system for safer printing as well as a touch screen that is easy to operate. All in all, the printer is an interesting one because not only is it one of the larger IDEX offerings on the market, but it is more affordable than many other industrial solutions with similar features and characteristics. You can find out more about the MD-400D as well as other solutions from MINGDA 3D HERE.

What do you think of the MINGDA MD-400D 3D printer? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: MINGDA 3D

Desde Cali, Colombia DE PLANTAS MEDICINALES CORDIAL SALUDO, REQUIERO INFORMACIÓN, GRACIAS.