Midlands 3D Unveils UK’s Most Automated Polymer 3D Printing Facility

It was announced this month that Midlands 3D, a British company based in Stone, Staffordshire, has officially marked the opening of what is believed to be the most automated polymer 3D printing production facility currently operating in the United Kingdom. This move marks a significant milestone in the ongoing shift of additive manufacturing from prototyping to high-volume, end-use part production.

Over recent years, 3D printing has quietly evolved into a vital manufacturing technology, and Midlands 3D has been at the forefront, investing heavily in advanced tools, machines, and automation to meet rapidly growing customer demand. The company recently quadrupled its floor space and upgraded its fleet of HP Multi Jet Fusion (MJF) printers by integrating automated build unit change systems. This technology enables printers to automatically swap completed build units and begin new jobs within minutes, allowing continuous production that cuts costs and lead times.

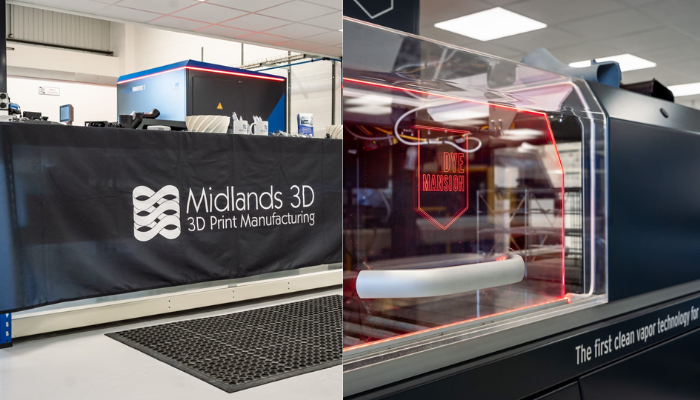

Midlands 3D showcased their new HP Multi Jet Fusion Printers.

François Minec, Vice President and Global Head of Sales at HP Additive Manufacturing Solutions, hailed Midlands 3D’s facility as a prime example of UK manufacturing innovation. “This level of automation and scale proves that additive manufacturing can deliver both lower costs and faster turnaround at volume,” Minec said. “Midlands 3D is setting a benchmark for how British industry can harness advanced technology to thrive globally.”

Beyond printing automation, Midlands 3D has invested in DyeMansion’s Powerfuse vapor smoothing system, enhancing its finishing capabilities with smoother, stronger, scratch-resistant and waterproof part surfaces. Together with deep dye coloring and Polyshot surfacing, these finishing options open doors to industries demanding both performance and aesthetics.

The facility will also house the new DyeMansion Powerfuse Vapor Smoothing System

Founder and Managing Director Paul Moloney emphasized the company’s evolution, “Last year, production manufacturing overtook prototyping as our core business. The expansion you see today reflects that tipping point and our commitment to keeping pace with this explosive market. Many industries are only beginning to explore 3D printing’s potential for volume manufacturing, and being centrally located in the Midlands places us perfectly to support the entire UK supply chain.”

The company’s recent open day invited industry partners and customers to explore the new HQ and learn about Midlands 3D’s expanded capabilities firsthand. A standout highlight was the display of two British Touring Cars outfitted with over 100 3D printed parts developed in collaboration with the WSR Racing team. These components have helped the team achieve record-breaking success, demonstrating the reliability and competitive advantage of additive manufacturing in high-stakes motorsports.

Midlands 3D also showcased their collaboration with the WSR Racing team on two new touring cars.

As Midlands 3D continues to lead the UK’s additive manufacturing revolution, the company invites businesses across automotive, healthcare, consumer goods, marine, and UAV sectors to explore how automation and advanced finishing can transform their production strategies. If you would like to learn more about this new facility, click HERE.

How do you see automation reshaping manufacturing in the UK? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*All Photo Credits: Midlands 3D