Microfluidic channels 3D printed for the first time by UMN

Researchers at the University of Minnesota partnered with the U.S. Army Combat Capabilities Development Command Soldier Center to 3D print unique fluid channels at the micron scale. The ability to additively manufacture such microfluidic channels can potentially automate the production of diagnostics, sensors, and assays used for a variety of medical tests. Notably, the UMN team is the first to 3D print these structures on a curved surface, which is the first step towards printing directly on the skin for real-time sensing of bodily fluids.

What is microfluidics? It is a rapidly growing field involving the control of fluid flows at the micron scale. Microfluidics are used in a wide range of application areas including environmental sensing, medical diagnostics, such as COVID-19 and cancer, pregnancy testing, drug screening, and more. Globally, the microfluidics market is worth billions of dollars.

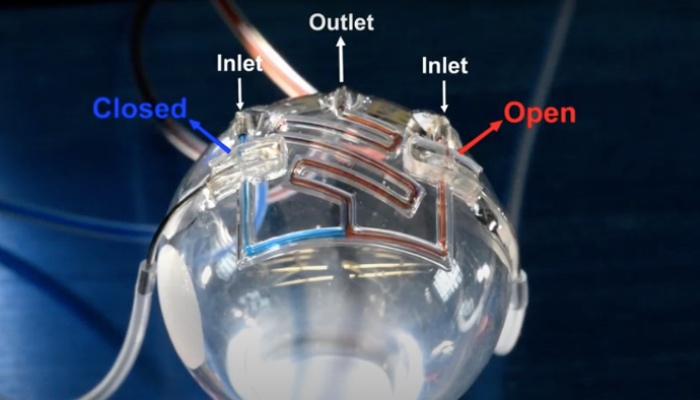

The 3D printed microfluidic channels. (All image credits: University of Minnesota)

Typically, microfluidic devices are fabricated in a controlled-environment cleanroom using a complex, multi-step technique called photolithography. But in this new study, the researchers were able to create microfluidic channels in a single step thanks to 3D printing. The team used a custom-built 3D printer to directly print the channels onto a surface in an open lab environment. The channels are about 300 microns in diameter – about three times the size of a human hair (one one-hundredth of an inch!). The team showed that the fluid flow through the channels could be controlled, pumped, and re-directed using a series of valves.

Why is this advancement considered to be groundbreaking? 3D printing these microfluidic channels outside of a cleanroom setting could provide for robotic-based automation and portability in producing these devices. In fact, 3D printing these devices without a cleanroom means that diagnostic tools could be printed by a doctor right in their office or printed remotely by soldiers in the field.

Michael McAlpine, a University of Minnesota mechanical engineering professor and senior researcher on the study explained, “This new effort opens up numerous future possibilities for microfluidic devices. Being able to print on a curved surface also opens up many new possibilities and uses for the devices, including printing microfluidics directly on the skin for real-time sensing of bodily fluids and functions”. The research paper was published in Science Advances, a scientific journal published by the American Association for the Advancement of Science (AAAS). You can read the research paper HERE.

The channels in the process of being 3D printed onto a sphere.

What do you think about the unique 3D printed microfluidic channels? Let us know in a comment down below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!