3D printed metamaterials to control sounds and vibrations

A team of researchers from Viterbi University in Los Angeles has found a new way to control sound and vibrations through 3D printing. The team has developed 3D printed metamaterials that are able to block sound waves and mechanical vibrations at a distance using the magnetic field.

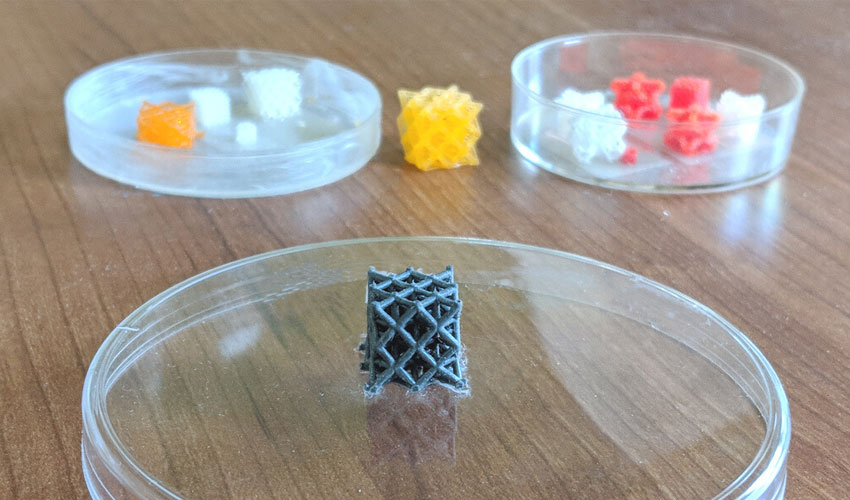

Research on 3D printing materials is accelerating with specific goals: to create something lightweight, create a solid structure or increase the speed of the printing process. This time, we are interested in metamaterials, an artificial composite material that has electromagnetic properties that are not found in any natural material. They are usually built in fixed geometries, which means that their properties are always stopped. A point that has been exceeded by this team of American researchers using 3D printing.

Metamaterials controlled by the magnetic field

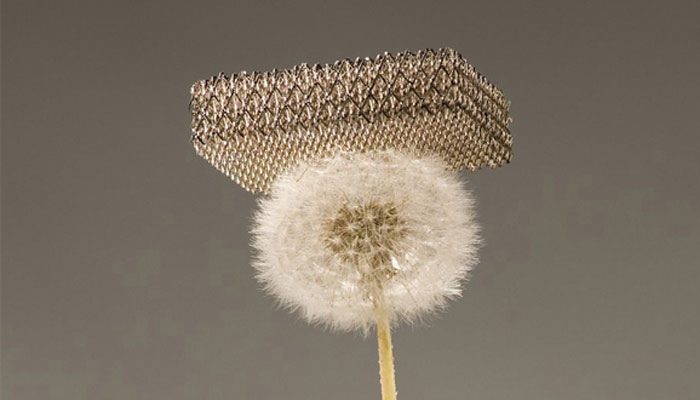

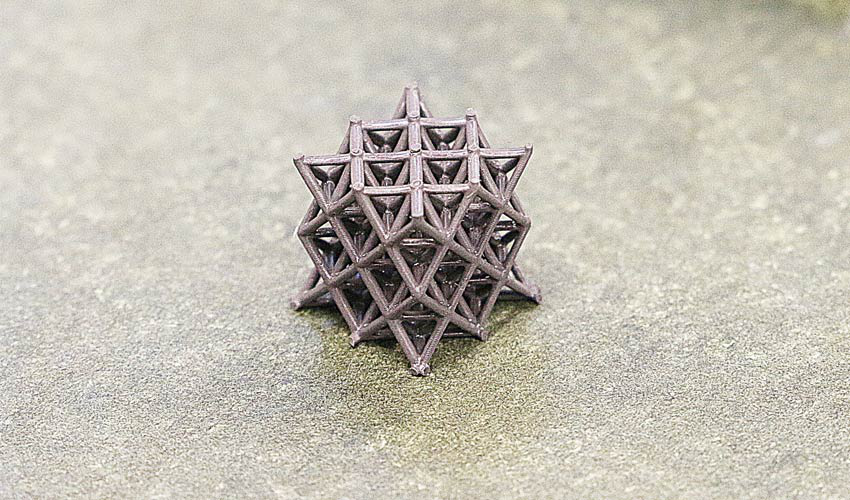

Led by Professor Qiming Wang, the team explains that their metamaterials have the ability to block sound waves and mechanical vibrations due to their reticular structure. It is also loaded with iron particles, which means that a magnetic field could be used to deform it, changing its properties. The magnetic field compresses the material, but unlike a physical contact force such as a metal plate, the material is not constrained. As such, when an acoustic or mechanical wave comes into contact with the material, it disturbs it, generating the unique properties that block the sound waves and the mechanical vibrations of certain frequencies. This can be useful for various applications such as noise suppression or vibration control, but also to create camouflage devices and more efficient communication systems.

“When you fabricate a structure, the geometry cannot be changed, which means the property is fixed,” explained Qiming Wang, USC Viterbi Assistant Professor of Civil and Environmental Engineering. “The idea here is, we can design something very flexible so that you can change it using external controls. You can apply an external magnetic force to deform the structure and change the architecture and the geometry inside it. Once you change the architecture, you change the property. We wanted to achieve this kind of freedom to switch between states. Using magnetic fields, the switch is reversible and very rapid.”

Little is known about the additive manufacturing process used, but Professor Wang explains that today they can print their materials with a diameter of between one micron and one millimeter. A smaller diameter would control the higher frequency waves while a larger one would affect the low-frequency waves. Find more information on the University’s official website.

What do you think of these metamaterials? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!