How will the health crisis impact the metal AM market in the next decade?

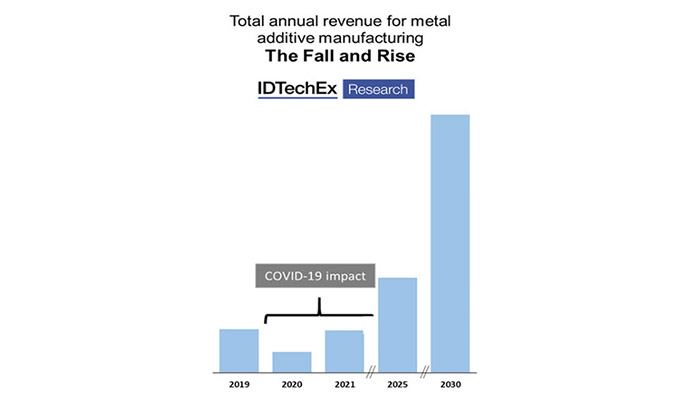

Over recent years, metal additive manufacturing experienced greater growth than other plastic 3D printing processes such as FDM or SLS. Mainly used for prototypes, tooling, and replacement parts, the industry also witnessed this technology being used for production runs of end-use parts. The initial success of this technology was found in highly industrial segments such as aerospace and defense, but also within the medical and dental sector. It was expected, according to industry experts, and further supported by market studies, that the metal AM market would continue to experience strong growth during the next few years. However, the health crisis brought on by the COVID-19 pandemic shows a strong impact on growth for the next two years.

In a recent study, “Metal Additive Manufacturing 2020-2030”, published by IDTechEx, the market research firm evaluates the effects of the COVID-19 global pandemic on the additive manufacturing industry, and more precisely on metal. It explains that this segment is experiencing a strong decline in the second half of 2020, with “multiple years needed for recovery”. IDTechEx’s study explains that there is good evidence that pre-arranged investments, certifications, and orders have all carried on. Furthermore, there is also the view point that AM gained importance during the pandemic. Whilst this might hold true in some cases, media coverage of the capabilities of 3D printing to address vulnerabilities in our current supply chains could make us think that the market impact was absorbed. However, this doesn’t seem to be the case in reality.

A 3D printed valve. AM manufacturers addressed vulnerabilities in their supply chain and capabilities were demonstrated in essential circumstances during the pandemic.

As the report highlights, the market impact has been profound and the recovery will not be immediate. More precisely, Dr Richard Collins, Principal Analyst at IDTechEx writes: “The market has fallen in the immediate timeframe, as both internal and client operations ground to a halt for large parts of Q1 and Q2 2020. The short-to-mid-term recovery will differ for each sector with the longest recovery to be for civil aviation. The material demand is forecast to “spring back” faster, but the printer sales will take longer to recover, temporarily stagnating the total installed base.”

The report doesn’t solely focus on the next few years but on the next decade. Therefore, after this first setback, a mid to long-term growth is still anticipated for the AM industry. Part of the reason for this will be due to end users gaining back confidence in the process and the value of investing in metal additive manufacturing again. However, this industry is still in a stage of innovation, which means that the next generation of technologies will gain more traction and within the next decade, a more diverse installation base will be observed.

Additionally to providing market analysis, in this report IDTechEx is cutting through the marketing strategies employed by companies to differentiate their technologies. Therefore, the report provides critical benchmarking studies of these processes; an essential process for identifying gaps in the market and end-use applications. You can find more information on material opportunities and metal end-use applications HERE. How do you think the health pandemic has and will affect the metal AM market? Let us know in a comment below or on our Facebook and Twitter pages your comments. Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!