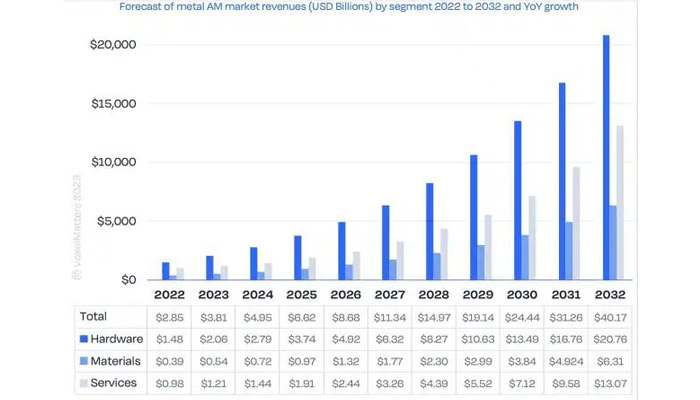

Metal Additive Manufacturing Market Expected To Have Generated $2.85 Billion in 2022

A new report on the metal 3D printing market estimates that its revenues reached $2.85 billion in 2022, corresponding to year-on-year growth of 26%. Published by VoxelMatters Research, it underlines the importance of additive manufacturing machines in this sector. Indeed, it is 3D equipment, and therefore the development of the technology, that has generated more than half the revenue, followed by the services and materials. In terms of business sectors, aerospace is the clear winner. If growth continues at this rate, the market could reach $40 billion by 2032 – a much more attractive estimate than the one made last year by IDTechEx.

This study surveyed over 400 companies working in the metal additive manufacturing sector, including 3D equipment manufacturers, materials manufacturers, and service providers. Over 170 tables and graphs within the report cover multitudes of data and analysis of verticals such as automotive, medical, aerospace, energy, and consumer goods. The report also provides a comprehensive overview of metal 3D printing technologies, focusing on lesser-known processes such as cold spraying and friction stir welding. The aim is to show that there are other possibilities besides mainstream powder-based processes.

Predicted growth in the metal 3D printing market (Image credits: VoxelMatters Research)

We haven’t got our hands on the full report yet, but it seems to highlight the verticals that use metal 3D printing, with aerospace at the forefront. This is hardly a surprise, given the sector’s rapid adoption of additive manufacturing for tooling, prototyping, and finished parts. Market giants such as Airbus and Boeing have invested in dedicated centers, with several metal solutions enabling them to meet the demands of their sector. Certain obstacles remain and need to be overcome, such as the certification of processes and materials, but progress is rapid and the market is more mature than before.

In terms of players, Germany is a pioneer of the technology, and more specifically of the laser-melting powder bed process, with historic manufacturers such as EOS, Trumpf and SLM Solutions. In Asia, Chinese companies are more focused on powder-based processes, while Japan seems to be specializing in DED technologies. Finally, the study underlines that the American market is topping the charts with the most national players generating the highest revenues. The U.S. market is therefore very active and dynamic, driven by players such as Desktop Metal, GE Additive, 3D Systems and Velo3D.

A 3D printed gearbox for a Boeing Chinook helicopter (Image credits: Boeing)

The future looks bright for metal additive manufacturing, even if it’s still a long way off from the figures for the polymer market. To access the full study, it is available for order HERE.

Do you use metal 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.