The Metal 3D Printer Manufacturers From Around the World

Metal additive manufacturing encompasses a whole range of processes that are becoming increasingly popular with manufacturers. For several years now, industry giants have been equipping themselves with solutions to produce high-performance, lighter, customized parts that consume less energy. The Wohlers 2024 report showed a 24.4% increase in sales of metal 3D printers over the previous year. But what exactly are the machines available on today’s market? To make it easier for you to understand the sector, we’ve divided these metal 3D printers by manufacturing process: powder bed fusion, directed energy deposition, material extrusion, electron beam melting, binder jetting and other technologies. Click on the technology of your choice to go directly to the associated machines!

- See all the powder bed fusion printers

- See all the directed energy deposition printers

- See all the material extrusion printers

- See all the electron beam melting printers

- See all the binder jetting printers

- See all the metal printers using other technologies

Powder Bed Fusion Printers

3D4MEC, The Italian Startup Focusing on Steel and Brass

Italian company 3D4MEC, based in Bologna, specializes in the development and manufacture of metal 3D printers, specifically for steel and brass (a copper and zinc alloy). They have two product lines, both of which use laser powder bed fusion technology. On the one hand, there is the 3D4STEEL 3D printing system, specialized in non-reactive steel powders, fully customized for each manufacturer’s production requirements. On the other hand, there is the 3D4BRASS manufacturing system for the creation of prototypes and pre-series directly in brass, without the use of molds or intermediate steps, thus reducing lead times and delivery times. Thanks to 3D4MEC solutions, greater practicality and ease of industrial production are guaranteed, while maintaining a high quality for the final parts.

Photo Credits: 3D4MEC

3D Systems Offers Metal 3D Printers Among Other Solutions

3D Systems is one of the world’s pioneers and leaders in 3D printing. The company made its mark on the industry back in the 1980s, when it entered the market with its stereolithography technology. Since then, it has continually innovated, particularly in the field of 3D metal printing with its Direct Metal Printing (DMP) technology. This process uses a high-precision laser to fuse layers of metal powder, enabling complex parts to be manufactured with great precision. 3D Systems’ range of metal 3D printers comes in several formats to meet a variety of industrial needs. There’s the large-format DMP Factory 500, while the DMP Flex 350 Dual and DMP Flex 350 Triple are ideal for medium-sized production. In addition, the DMP Flex 200 offers a compact solution without sacrificing quality.

Photo Credits: 3D Systems

Aconity3D

Aconity3D offers a diverse range of standard 3D printing machines designed to meet a wide range of industrial applications. One of the brand’s key strengths lies in its modular platform, which enables equipment to be easily adapted to meet specific user requirements. Since its inception in 2014, Aconity3D has specialized in developing laser powder bed fusion systems. Its range includes machines from a single laser, such as the AconityMINI, to more advanced configurations incorporating up to six lasers, such as the AconityX. Between these extremes are other models, such as the AconityMIDI+, AconityTWO and AconityMICRO.

The AconityTWO from Aconity3D. (Photo Credits: Aconity3D)

AddUp, Metal 3D Printers From France

AddUp was born of a strategic alliance between two big names in industry: Michelin and Fives. The company quickly established itself in the field of metal additive manufacturing with the launch of its first machine, the FormUp 350. Based on laser powder bed fusion, this printer offers a printing volume of 350 x 350 x 350 mm. It is compatible with a wide range of materials, including stainless steel, nickel, titanium and aluminum alloys. It is ideal for a wide range of applications, from large production runs of medical prostheses to small series of structural parts for the aerospace industry. AddUp also offers a more advanced version of this machine: the FormUp 350 Evolution. This top-of-the-range version opens up new possibilities for large part production, thanks to a 185% increase in volume over the standard model.

Photo Credits: AddUp

Alpha Laser

The German company Alpha Laser specializes in the development of laser metal additive manufacturing systems offering powerful, precise and easy-to-use solutions for industrial applications. Among its most outstanding product ranges are mobile, open and closed systems, depending on the needs of each application. The crown jewel is the AL3D-METAL, a compact and precise metal 3D printer, ideal for jewelry and high-end applications. It uses a 200 W laser and a closed powder handling system. In addition to being compatible with metals such as gold, silver, titanium and steel, it achieves a density of 99.9% and enables fast material changes. Alpha Laser equipment combines high power, laser safety, ergonomics and durability, offering reliable and efficient tools for daily work.

Photo Credits: Alpha Laser

BLT

Bright Laser Technologies (BLT) is a Chinese company that offers advanced metal 3D printing solutions. Its equipment stands out for its multi-laser technology, with up to 26 fiber lasers that accelerate manufacturing by up to 70% compared to conventional systems. BLT controls the entire process, from the production of metal powders (titanium, nickel, stainless steel, aluminum) to the optimization of printing parameters, ensuring consistent and repeatable results. It has two ranges of 3D printers, the S series (with 10 different machines) and the A series. Both series can manufacture complex geometries without support structures at angles of less than 30°, thus accelerating post-processing. With a focus on speed, efficiency and quality, BLT machines are used in demanding sectors such as aerospace, automotive, medical and electronics.

Photo Credits: BLT

Colibirum Additive

Perhaps not everyone is familiar with Colibirum Additive. However, this company is an old hand in a new guise. Behind Colibrium Additive is none other than GE Additive, which once also acquired Concept Laser and Arcam EBM. However, GE rebranded in spring 2024, which is why GE Additive now operates under the new name Colibrium Additive and is subordinate to GE Aerospace, although this new “packaging” has not changed the company’s activities. Colibrium Additive continues to provide high-performance solutions for 3D metal printing, offering advanced machines, materials and services. The company focuses on three powder processes: EBM (called EB-PBF at Colibrium Additive), LPBF and metal binder jetting for large parts on an industrial scale.

Photo Credits: Colibrium Additive

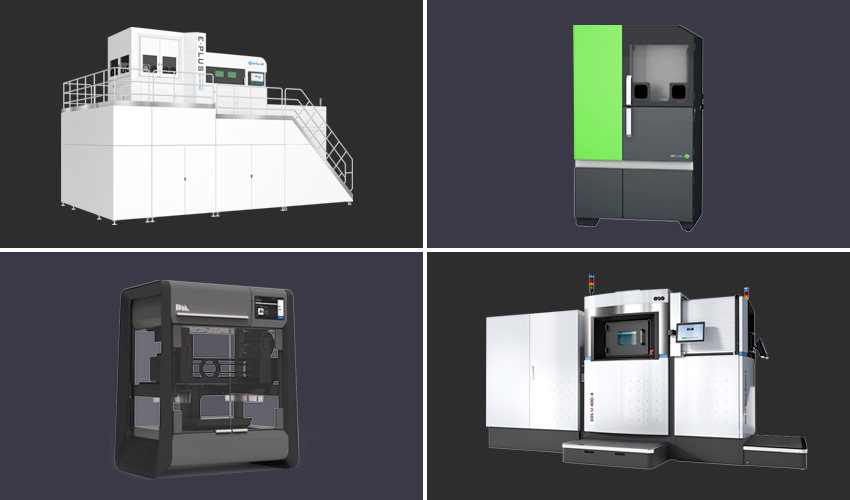

Eplus3D

Eplus3D already has over 30 years of experience in the additive manufacturing industry. The Chinese company has positioned itself internationally, as evidenced by its locations in Stuttgart and Houston. The focus of Eplus3D is on industrial 3D printing solutions. Eplus3D covers both polymers and metals, which are additively processed in a powder bed. With its industrial 3D printers, Eplus3D addresses a wide range of industries: aerospace, automotive, medical, energy and many more. In addition to printing systems, Eplus3D also focuses on software, services and the research and development of advanced materials for additive manufacturing. In the past, Eplus3D has demonstrated its expertise in numerous collaborations. For example, it presented the world’s largest 3D-printed rocket engine together with LEAP 71 at Formnext 2024. Eplus3D also worked with MÖVE and presented the first 3D-printed titanium bicycle frame with an integrated battery.

The EP-M2050 3D metal printer with a build area of 2050 x 2050 x 1100 mm. (Photo Credits: Eplus3D)

EOS

Based in Krailling near Munich, EOS is one of the pioneers of additive manufacturing. With its 3D printing systems for polymers and metals, its services and materials, EOS offers a wide range of AM products. The family business was founded in 1989 and since then, sustainability, innovation and responsibility have been at the heart of EOS’ work. The company’s flagship products include its DMLS solutions: the EOS M 290 series, the EOS 300 series for high productivity and the EOS M 400 series. More than 20 alloys have been validated for all these systems to date. Customers can additively process aluminum, cobalt-chromium, copper, nickel-based alloys, stainless steels and many more. AMCM (Additive Manufacturing Customized Machines) is also part of the EOS Group. This sister company was founded to offer customers additional AM solutions that are not fulfilled by standard products.

EOS M 400 series (Photo Credits: EOS)

Farsoon Technologies

With headquarters in China, North America and Europe, Farsoon Technologies offers a range of metal printing solutions for a variety of applications. The company specializes in laser powder bed fusion. The Chinese manufacturer, which was founded in 2009, claims it is the leading supplier when it comes to industrial 3D printing in China. However, the company has also gained a foothold at the international level. For example, the CAMS FS421M 3D printer was launched on the European market in 2022. This metal 3D printer, with a machine size of 2770×3220×2350 mm, can produce parts as large as 425×425×420 mm. It uses laser powder bed fusion, and users have the option of a dual laser. As for the compatible materials, the metal printer can manufacture with copper, titanium and aluminum, among others.

Matsuura

Based in Japan, the metal 3D printer manufacturer was founded in 1935 and currently employs 300 people worldwide. It markets hybrid 3D printers that combine CNC milling and subtractive manufacturing processes with additive manufacturing such as powder bed fusion. The company sells two models, the LUMEX Avance-25 and the LUMEX Avance-60.

Photo Credits: Matsuura

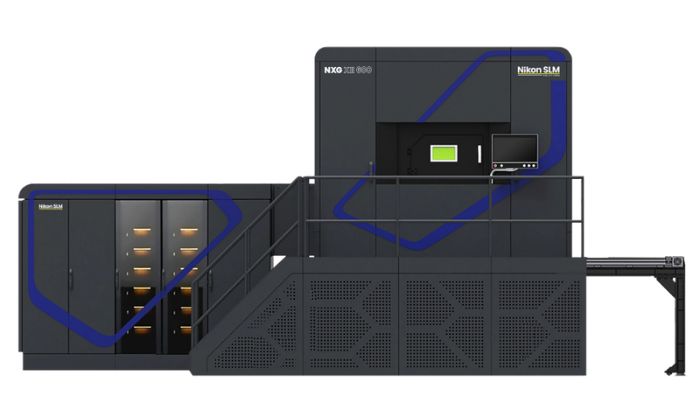

Nikon SLM Solutions

The historic metal 3D printing company SLM Solutions was acquired in January 2023 by Nikon, becoming Nikon SLM Solutions. This currently has 7 metal 3D printers on the market: the SLM 125, SLM 500, SLM 280 2.0, SLM 280 PS, SLM 800, and the newer NXG XII 600 and NXG 600E. These 3D printers are based on the patented Selective Laser Melting (SLM) technology. The latest NXG series is designed for metal additive manufacturing in series and large format for industry.

Photo Credits: Nikon SLM Solutions

One Click Metal

One Click Metal is a German company based in Tamm, near Stuttgart, which specializes in manufacturing PBF metal 3D printer solutions. Its main objective is to simplify and make metal additive manufacturing technology accessible to everyone. In addition, One Click Metal demonstrates its commitment to sustainability by using 100% electricity from renewable sources. One Click Metal offers a complete package for metal 3D printing consisting of a starter package called M PREP, M ONE software where to load designs made in CAD programs, the M PRINT 3D printer and the M PUREpro, a 2-in-1 unpacking and sieving station. The M PRINT 3D printer features a powerful 200W fiber laser, which guarantees high productivity and precision in the printing process. Its build volume is 150 mm x 150 mm x 150 mm and machine dimensions are 1.1 x 1.9 x 0.79 m, weighing 440 kg.

Photo Credits: One Click Metal

Prima Additive

Prima Additive, formerly part of the Prima Industrie Group, is now part of the Japanese Sodick Group. Based in Turin, Italy, the company offers 3D powder bed (PBF) and DED 3D printers and is active in various industries such as aerospace, automotive, medical and dental. The manufacturer currently offers several PBF metal 3D printing solutions, including the Print Sharp 150, Print Genius 150 and Print Green 150, the 300 Family series of printers, and the Print Genius 400 with a print volume of up to 430 x 430 x 1000mm and a customizable laser configuration.

Photo Credits: Prima Additive

Renishaw, the UK-Based Metal 3D Printer Provider

Renishaw is a British additive manufacturing company based in Gloucestershire, UK. The company specializes in creating industrial 3D printers that create lightweight, bespoke metal models quickly using powder bed fusion technology. Renishaw offers a unique line of 3D printers under the RenAM 500 series, designed to meet different industrial needs. This series includes the RenAM 500 Flex, RenAM 500Q, RenAM 500 Ultra and the newest model, the RenAM 500D. Each of these models offers a 3D printing solution for different needs, as well as different speeds and build sizes.

Photo Credits: Renishaw

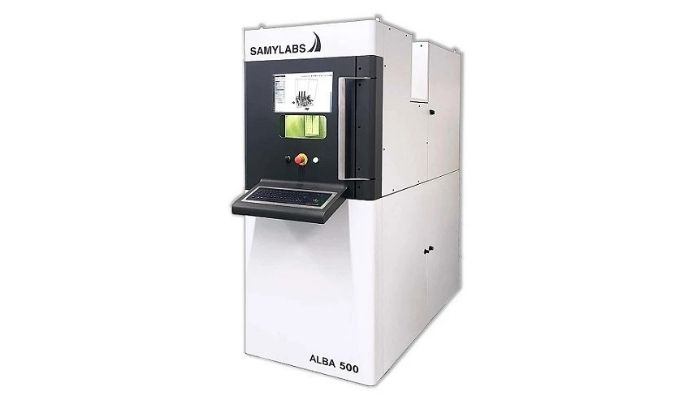

SamyLabs

SAMYLABS is a manufacturer that was founded in 2016 and is based in Vizcaya, Spain. The company specializes in the design, production and marketing of metal 3D printers. They especially focus on making metal 3D printing more accessible for small businesses, training centers and universities. The first 3D printer the manufacturer launched was the Alba 300. It was developed in conjunction with ONA, showcasing collaboration and excellence in additive manufacturing technology. It is a printer designed to operate in both industrial and office environments. Recently, the company has introduced the Alba 500, a new device similar to the previous model, but with some improvements. For example, it has a larger print volume, a double filtering system and a 500 W laser system, surpassing the 200 W of the previous machine.

Photo Credits: SAMYLABS

Sharebot

An Italian company, Sharebot, started at the end of 2013 when one of the founders read an article about Andrea Radaelli, one of the first people in Italy to create a 3D printer. They work in a number of industries. They have several printers available, though most use SLS. However, they do have one metal printer, the Sharebot metalONE. The Sharebot metalONE uses Direct Metal Laser Sintering and is aimed at the research and production of small and medium-sized metal parts. The print area is 65 x 65 x 100 mm (2.6 x 2.6 x 3.9 in) and has a layer height of 5 micron – 200 micron. The printer is compatible with 316L Steel and Cobalt Chrome (CoCrMo). Sharebot mentions that the printer could be used in the dental, jewelry, and industry sectors.

Sisma, 3D Printers for Specific Industries

Sisma is an Italian company that has been operating in different industries since the 1960s. A few years ago, the company decided to explore additive manufacturing. Currently, its 3D printer offering focuses on two models, the MYSINT100 and the MYSINT200, both based on laser metal fusion (LMF) technology. The MYSINT100 incorporates a patented Tilting Coater that reduces coating times and allows complete customization of manufacturing parameters. It is a machine primarily for applications in the jewelry and luxury industry, and the company stresses that it is designed not only for prototyping, but also for mass production. The MYSINT 200 represents the latest generation of Sisma printers. It is specially designed for industrial and medical applications, including work with reactive metals. In this way, Sisma offers customized, high-performance solutions in metal additive manufacturing.

Photo Credits: Sisma

Sodick

The Japanese company Sodick has been in business since the 1970s and has been manufacturing high-quality EDM machines since the beginning. In the course of its almost 50 years of activity, Sodick has also developed 3D metal printers based on LPMS technologies. The company offers two different printer options: The OPM series and the LPM series. The OPM technology combines industry-leading laser sintering technology with high-speed milling – allowing a final product to be produced in a single automated operation. According to the manufacturer, switching between traditional manufacturing technology and 3D printing in just one machine improves the accuracy and finish of the end product.

The OPM250L and OPM350L are currently available from Sodick. The OPM250L is the smaller printer with dimensions of 260x260x260mm, while the OPM350L has larger dimensions (360x360x344mm) with the same high quality. Both offer impressive reliability and accuracy and feature a powerful 500W laser and a 45,000 rpm milling spindle. In the LPM series, Sodick currently only offers the LPM325S, which, in contrast to the OPM series, is particularly impressive with its speed and high-performance 500W laser.

The Sodick LPM325S. (Photo Credits: Sodick)

Trumpf, Metal 3D Printing for Tooling

Trumpf is another German company that is active in many different industries, including 3D printing. Within the 3D printing industry, Trumpf Laser GmbH sells 3D printers of two different technologies. Of interest for this ranking is the so-called “Laser Metal Fusion,” which is similar to laser melting. Trumpf offers several 3D printers in the Truprint series: The TruPrint 1000, Truprint 2000, TruPrint 3000 and the TruPrint 5000, which differ in size and performance (and price). The 1000 series uses two 200W lasers and is designed to fit into any laboratory, whether in the dental sector or in universities. The Truprint 2000 is primarily aimed at applications in the tool industry, as well as in the dental, medical or general industry and uses a 500W laser. The Truprint 3000 is a flexible solution for all areas of industry and, thanks to its universal features, can be fully adapted to individual customer requirements. With two 700W lasers, this option offers simultaneous exposure of the entire build area. The Truprint 5000 features a highly productive, semi-automated 3D printing system that, thanks to three 500W full-field multilasers, promises optimum surface quality of the end product as well as a fast processing time.

Velo3D, Metal Technologies Without the Need for DfAM

Velo3D is an American manufacturer whose founder, Benny Buller, wanted to introduce metal technologies to other companies by developing the 3D software Flow™. The goal was to accelerate the design process in additive manufacturing, as well as collaborate with engineers in the design and preparation of parts for 3D printing. In 2018, they developed their 3D printer Sapphire™ with the patented technology called Intelligent Fusion™, which is part of the powder bed fusion family. This system specializes in the development of parts with complex geometry – high-quality, repeatable results for the most demanding metal components are possible thanks to Sapphire technology. With two 1kW lasers, the production of highly detailed products without support structures and with highly complex designs is no longer a problem. The Sapphire XC model has eight 1kW lasers and a larger printing plate, which makes it easier to print large-format components. Or, as Velo3D itself describes the Sapphire series: “Designed to print the impossible.”

The Sapphire XC (Photo Credits: Velo3D)

Xact Metal

Founded in 2017, Xact Metal is located in Pennsylvania and has always aimed to make metal 3D printing more affordable. The manufacturer currently offers two machines: the XM200G and the XM300G, both based on the laser fusion process. The former is currently on the market and offers a print volume of 125 x 125 x 125 mm, as well as a single or dual laser, depending on requirements, up to 400W. In terms of applications, Xact Metal targets the aerospace, dental, manufacturing and automotive sectors. Its other machine, currently under development, is larger and faster, designed for larger production runs and larger parts.

To the left, the XM200G; to the right, the XM300G. (Photo Credits: Xact Metal)

ZRapid’s iSLM Range Is Taking the World by Storm

Another major player coming from China is ZRapid. The powder-bed solutions providers, which work with technologies like SLM and LPBF in metal, as well as SLA for polymers, have seen rapid expansion in recent years. Indeed, the company has more than 5,500 industrial 3D printers installed in China, along with even more in over 40 other countries. This includes an increased presence in Europe, thanks especially to its collaboration with ANiMA, based in Greece, with the iSLM range of metal 3D printers. This line includes four machines that differ in print volume, going from 160 mm x 160 mm x 210 mm with the iSLM160 up to the iSLM600QN, which boasts a build volume of 600 mm x 600 mm x (600 – 1300 mm) and which has been optimized for automated industrial production of large parts. The company is also notable for its growing focus on innovative design, including robotics and artificial intelligence for next-generation additive manufacturing.

Some of ZRapid’s solutions in a factory (photo credits: ZRapid)

Directed Energy Deposition Printers

Directed Energy Deposition (DED) is a technique based on a metal wire or powder, depending on the machine used, which is melted using a focused energy source, be it a laser, plasma arc or electron beam. DED offers several advantages, such as the ability to design large metal parts, but also the possibility of repairing existing components. For a list of DED 3D printers, please see our dedicated article HERE.

Material Extrusion Printers

Desktop Metal

Desktop Metal is an American company that, since its founding in 2015, has focused on lowering the cost of 3D printing complex metal objects and accelerating the production of those metal parts. Desktop Metal’s big goal is to take additive manufacturing to the next level and permanently change mass production. The company defines this vision as “AM 2.0.” Although Desktop Metal focused more on extrusion with metal in its early days, the company is increasingly expanding into metal binder jetting. Desktop Metal currently carries four series of systems with printers in its range, which mainly work with binder jetting technology. However, one of the four printers, the Studio System 2, uses Bound Metal Deposition, a type of extrusion technology. The two-step system is comprised of a printer and furnace. With a fully re-engineered materials library, printed parts can be placed directly into the furnace, without the need for the typical solvent debinding phase. In 2024, the company was acquired by Nano Dimension.

The Studio System’s printer (left) and furnace (right). (Photo Credits: Desktop Metal)

Markforged

Markforged was founded in 2013 by Greg Mark and first focused on carbon fiber 3D printing. Since then, the company has started manufacturing metal additive manufacturing systems. In addition to its desktop and industrial composite 3D printers, the company offers three metal 3D printers: the FX10 and Metal X Sytem employs FFF technology, and the PX100 uses binder jetting. What’s more, the FX10 boasts the ability to print metal and composite parts. In 2022, Markforged acquired Digital Metal and its technology, integrating its design and printing platform, Digital Forge. Digital Forge is AI-based, connecting software, 3D printers and materials to improve efficiency. Markforged’s goal is to eventually produce high-precision metal end parts in large production runs, and to do so in a distributed manner through its global presence. Most recently, the company was acquired by Nano Dimension in 2024.

The FX10 (left) and Metal X System (right). (Photo Credits: Markforged)

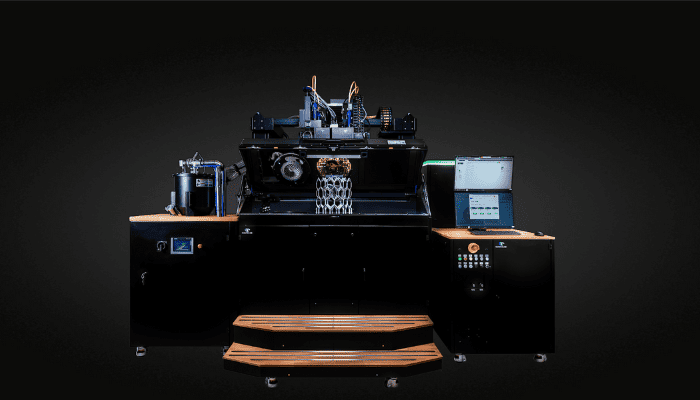

Pollen AM, Creator of the Pam o2 MC

The pam o2 MC 3D printer from French manufacturer Pollen AM is a pellet extrusion solution, compatible with both metal and ceramics. It offers a print volume of 300 x 300 and 2 to 4 extruders, depending on the desired configuration. Extrusion temperature rises to 450°C, while the platen heats to 150°C. On the metal side, the machine can design parts in several steel alloys – stainless steel 136L or 304L – as well as Cu999 copper. After printing, the user must go through a debinding and sintering stage to obtain the part’s final properties and consolidate the metal powder particles.

Photo Credits: Pollen AM

Triditive

Triditive is a Spanish company founded in 2013 that initially focused on training in FDM technologies and the development of 3D printer kits. Today, the startup is best known for its metal additive manufacturing solution called AMCELL. The AMCELL 8300 is an industrial 3D printer compatible with metals, polymers and composites, even at the same time. This is achieved through automated modules based on AMD (Automated Multimaterial Deposition) technology, and it also allows for the production of metal parts by metal extrusion. This is followed by a sintering process to obtain a 100% metal part with improved surface quality. Triditive’s solution has undoubtedly demonstrated the potential of additive manufacturing, and specifically, the manufacture of metal parts with more optimal and flexible processes.

Photo Credits: Triditive

ValCUN

ValCUN is a young Belgian company that has developed a metal 3D printing solution using Molten Metal Deposition technology. Their Minerva solution produces parts by melting a metal filament, just as is done in the polymer 3D printing (FFF) process. The 3D printer is designed specifically for additive manufacturing of aluminum parts, but it comes with open parameters and an open material system. The data acquisition and nozzle architecture are also open, leaving the user free to modify the parameters for their own needs.

Photo Credits: ValCUN

Rapidia

Based in Vancouver, Canada, Rapidia has developed an innovative metal 3D printing technology. Called Metal Paste Deposition, this powder-free technique simplifies and streamlines the manufacture of complex metal parts. Its Conflux 1 printer makes it possible to produce components without the need for additional equipment for powder handling, stress relief or support removal. One of its outstanding innovations is the use of an evaporative support material, which disappears during final baking, enabling impossible geometries without mechanical post-treatment. This facilitates free design and accelerates the production of functional parts, from prototypes to short runs. Compatible with various metals, Rapidia offers a compact, efficient and scalable additive manufacturing solution, ideal for educational environments, laboratories and small industrial productions.

Photo Credits: Rapidia

Binder Jetting Printers

Powder bonding is a process compatible with certain metals. As its name suggests, it is a technology based on powder and a binder. The particularity of powder bonding is that it requires a debinding and sintering step after printing, which lengthens the manufacturing process. You can find out more about metal 3D printers based on binder jetting in our dedicated article HERE.

Electron Beam Melting Printers

EBM (Electron Beam Melting) 3D metal printing technology is very similar to the laser bed fusion process. One of the main differences is the heat source used: here, an electron beam is used to melt the metal powder, layer by layer. This process is only compatible with conductive metals and will enable the rapid design of dense parts. We invite you to consult our dedicated article HERE to find out more about all the EBM 3D printers on the market.

Metal 3D Printing: Other Technologies

ADMATEC, 3D Printing with Ceramics and Metal

ADMATEC is a Dutch 3D printing company founded in November 2013 after a successful research project for developing a ceramic technology. The company currently offers three printers under its ADMAFLEX series that run on resin technology based on direct light processing (DLP). The Admaflex 130 Entry is a printer for advanced ceramics that can be upgraded to the Admaflex 130 Evolution. The latter is an upgraded version that can print both ceramics and metal and incorporates an automatic mixing system that prevents material settling. Finally, the Admaflex 300 is a larger model designed for industrial applications. Its modular design allows customized configurations of printing volume and resolution.

Photo Credits: ADMATEC

Exaddon and its CERES Print System

Exaddon’s 3D metal printer, the CERES Print System, can print metal with sub-micrometer resolution, offering a very high level of detail. It has a chamber volume of 100 x 70 x 60 mm and prints at room temperature, with no post-processing necessary. Additionally, it can also print overhanging parts without any need for support structures, a rarity among metal AM technologies.

Grob

The GMP300 is the first additive manufacturing machine developed by GROB, a leading German manufacturer of industrial automation machines and systems. This innovative 3D printer utilizes Liquid Metal Printing (LMP) technology, also known as Molten Metal Printing (MMP). Thanks to its powder-free process, the GMP300 enables the safe and efficient production of near-net-shape components at high speed. According to GROB, the GMP300 offers customers reliable, efficient, and cost-effective plant technology with maximum production flexibility. The solution was specifically developed to enhance aluminum parts production. To learn more about The GMP300, HERE.

Photo Credits: Grob

SPEE3D, Producing the World’s Fastest Metal 3D Printer

SPEE3D was founded by Byron Kennedy and Steven Camilleri with the goal of making metal part manufacturing easier. So it’s hardly surprising that their SPEE3D printers enable a low-cost manufacturing process for metal additives worldwide. That’s because the power of kinetic energy is used for the process, rather than expensive, high-powered lasers or gases. The company offers four products, ACTIVAT3D Copper, LightSPEE3D, WarpSPEE3D and SPEE3Dcell, with the latter three each being metal printers. The LightSPEE3D and WarpSPEE3D 3D printers can print metal parts with diameters of 350 mm x 300 mm and 1000 mm x 700 mm, respectively, and are the world’s first metal 3D printers with patented SPEE3D technology. The manufacturer particularly emphasizes the excellent speed and low price. The SPEE3Dcell is integrated with a heat treatment furnace and a CNC 3-axis milling machine and is perfect for prototyping. The company has grown rapidly in recent years thanks to its work in defense and aerospace.

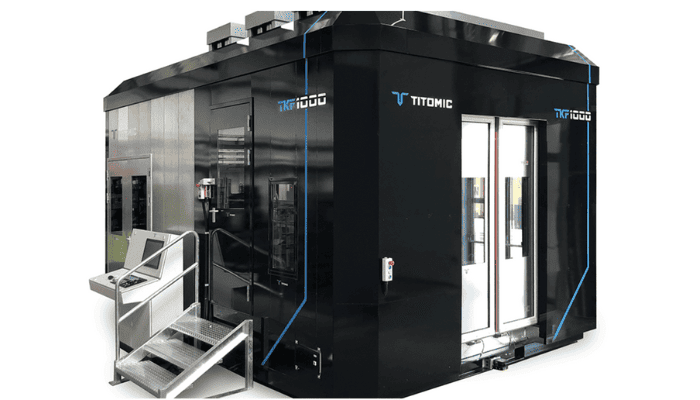

Titomic

Titomic is a company that transforms manufacturing methods in the aerospace, automotive and defense sectors to optimize the performance and durability of the parts produced. It stands out for its use of cold spray additive manufacturing technology, also known as cold spray. Among its flagship solutions, Titomic offers the TKF 1000 system, a 3D metal printing machine designed for large-scale production. This system incorporates advanced robotization with synchronized control over 6 axes, an intuitive touch interface for simplified operation, and a soundproof protective cabin, guaranteeing safety and comfort of use.

The TKF1000 System from Titomic (Photo Credits: Titomic)

Tritone

Tritone is an Israel-based manufacturer of metal and ceramic 3D printing solutions. Founded in 2017, the company supplies metal and ceramic parts to the automotive, medical, electronics and aerospace sectors. Tritone offers two solutions: the Dominant and the Dim. Both printers use so-called MoldJet technology, which can produce metal and ceramic parts on an industrial scale at particularly high speeds. It is ideally suited to complex, high-density structures. Tritone also supplies software for real-time on-site and remote control of the entire production cycle. According to the manufacturer, this should make the production of metal parts easier and more accessible.

XJet: 3D Metal Printing with NanoParticle Jetting Technology

XJet is an Israeli manufacturer of 3D metal printers and ceramic materials. The company was founded by 3D veteran Hanan Gothait, who is one of the co-founders of Objet. The company is primarily known for its groundbreaking NanoParticle Jetting™ technology, which has redefined additive manufacturing in the fields of metal and ceramics. XJet currently has two 3D printers on offer, the X Carmel 1400 and the X Carmel 5000. While the X 1400 is a high-specification model, the new generation of the X Carmel 5000 boasts four times higher productivity and no material waste, according to the manufacturer. Products can be produced within two to three days, while the printing process itself is highly automated.

The X Carmel 5000 (Photo Credits: Xjet)

What do you think of these metal 3D printer manufacturers? Which is your favorite? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

Do all sand and metal digital printers use a high temperature abrasive resistant gasket arounf the piston?

Found this article very interesting. All the product you mentioned in the post are looks cool. Thanks for sharing here.

Are you sure Sciaky is the oldest company on the list you say they were founded in 1939 but not when in 1939, if it’s after 1st of January 1939 they are the second oldest company on the list behind HP.

why 3d Micromac Gmbh are not a part of the long list you have here

Thank you. This article really helped me in my homework

Where’s Additive Industries?

Here are a few more for your list.

Open Additive’s Panda is a production-ready laser powder bed fusion system. https://openadditive.com/

Mitsubishi makes a laser wire metal DED system called the AZ600. Available in Japan and soon around the globe. bit.ly/435GUwG

Unfortunately this list NOT comprehensive:

https://www.meldmanufacturing.com/