Meet ROBOTOR, the Robotic Sculptor of Marble Statues

3D technologies are now used in a wide variety of fields, among them 3D scanning, 3D modeling and automation are revolutionizing both subtractive and additive production methods. One example is the experience of Giacomo Massari and Filippo Tincolini, founders of the companies ROBOTOR and TorArt who have used robotics combined with 3D scanning in the service of art and culture, or rather sculpture to be precise. Their anthropomorphic robot is capable of reproducing in a short time, and guaranteeing accuracy and detail, the greatest sculptures in history: Amore e Psiche, Canova’s Tersicore, the Arch of Palmyra and the Parthenon bas-reliefs are just some of the priceless works TorArt has been able to work on. Their mission? To simplify the work of the sculptor and multiply as much as possible the enjoyment of masterpieces that are often inaccessible or stored in major museums around the world. We interviewed the team of the two companies to learn more about their work and the synergy between the two!

3DN: Hi, Can You Introduce Us to ROBOTOR and TorArt?

3DN: Hi, Can You Introduce Us to ROBOTOR and TorArt?

ROBOTOR was born from the experience of two partners in the field of marble processing and the use of robots for sculpture making – Giacomo Massari and Filippo Tincolini. It is a company specializing in the integration of multi-axis industrial robots for stone milling – the most advanced technological solution for automated production processes.

In 2004, the two partners also founded the TorArt laboratory within the Carrara marble quarries, which today uses ROBOTOR’s robots to recreate the work of artists and designers from around the world. Names like Jeff Koons, Barry x Ball, Francesco Vezzoli, Vanessa Beecroft, Giuseppe Penone, Zaha Hadid, Maurizio Cattelan, and more have turned to TorArt. Along with them, major museums and corporations have also relied on us to reproduce works of art from the past that have been featured in media around the world.

3DN: What Is Your Main Goal?

We aim to maintain and consolidate the work of TorArt, which is already globally recognized as a benchmark for sculpture, and to make ROBOTOR known as the company that produces “robots for sculpture, born by sculptors,” robots that fit naturally into the operational flow of the company. Our goal is to eliminate wear and tear work steps related to sculpture, decrease lead times, and increase productivity and quality without the need for special skills thanks to ROBOTOR and OR-OS© self-programming software.

3DN: How Does the Sculpting Process Work With a Robot?

The entire ROBOTOR project stems from a precise philosophy that is the product of 18 years of experience in stone processing, which has guided the development of the system into its various components. The heart of ROBOTOR is OR-OS, a self-programming software for CNC milling developed in-house. Through intuitive interfaces, without the need for any specific programming skills, OR-OS allows anyone to use the robot even to perform complex jobs. OR-OS starts from a 3D file and automatically converts the model into toolpaths without operator intervention. It does this by selecting the type of shape to be made and the type of machining based on the timing and quality required.

The robot sits on a base designed in-house to hold all the necessary tools and is capable of withstanding the extreme conditions typical of stone processing while the arm and head are manufactured by partner technology companies. Thanks to sensors on the machine, milling is monitored in real-time for continuous 24-hour processing, meeting the need for precise control of processing time and cost.

Marble from the Carrara Quarries is some of the finest marble in the world.

3DN: Tell Us About the Reproduction of Canova’s Tersicore With ROBOTOR?

Tersicore is a work in white Carrara marble sculpted by Canova in 1811, now kept at the Magnani Rocca Foundation in Traversetolo, in the province of Parma. It precisely depicts Tersicore, the muse of dance and choral singing. The Carrara marble reproduction was made possible by 3D scanning of the original statue by TorArt. The OR-OS software, starting from the 3D file of the work, independently generated the program that allowed ROBOTOR to work the stone “recreating” the statue.

The life-size reproduction of the work (182cm high) was lent to the Isidoro Falchi Civic Archaeological Museum in Vetulonia (GR) as a contribution to the realization of the exhibition “In Dance Time. In harmony, grace and beauty.” The Tersicore shaped by the robot summarizes all the values of the Canovan original, but it lives a life of its own and has its own function of representation and “multiplication of memory.” Indeed, it was chosen not to impose on the replica with any hand finishing so as not to create confusion between copy and original.

3DN: What Are the Advantages of Using 3D Technologies for Your Industry Over Traditional Methods?

The use of robotic and 3D technologies fits into the traditional workflow that involves a creative ideation phase of the work to be created (sculpture, architecture, design) and leads to the creation of a sketch. The sketch can directly be a 3D file or a traditional clay sketch which is scanned to obtain the 3D file. At this point, what changes is that, instead of skilled artisans, it is the robot that performs all the steps of a job that is certainly wearisome. This means zero fatigue for the sculptor or operator, fewer hours of work, more accuracy, 24-hour operation, with the possibility for the operator to devote himself to other work.

3DN: What Are the Most Interesting Projects You Have Worked On and Those You Foresee for the Future?

Definitely, the replicas of great works of the past are the projects that have given us the most satisfaction especially because of the great international visibility we have obtained. In 2016, the scale reproduction of two-thirds of the Monumental Arch of Palmyra, a Syrian monument destroyed by ISIS in 2015, went around the world, used as a symbol of rebirth after the war. Thanks to images of the arch taken before the destruction, it was possible to create a 3D model sufficient for our robots to make a perfect replica. The result was a worldwide success! Another project was the creation of a replica of the Greek statue of Persephone Gaia of Tarentine, exhibited at the Altes Museum in Berlin. With our technology, we brought home a reproduction of the work visible today at the National Archaeological Museum in Taranto. Finally, in 2020 in just over 10 days we sculpted in marble Cupid and Psyche, one of Canova’s most famous works that the master of neoclassicism took five years to complete, in 1793.

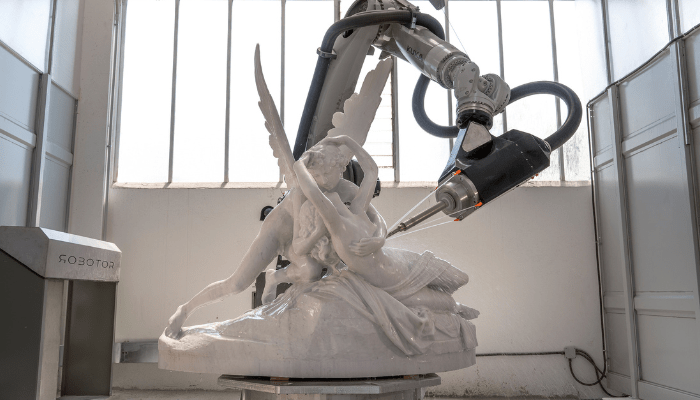

ROBOTOR sculpts a replica of Canova’s ‘Amore e Psciche’

Again, we started with the 3D file of the scan of the work on display at the Louvre in Paris, which ROBOTOR’s software used to program the robot. The replica of the original was created from a block of white Carrara marble weighing 10 tons and was on display in Rome as part of the “Eternal Beauty” exhibition, along with 170 other works from museums around the world.

We are also currently involved in solving one of the cultural controversies that has been raging for more than a century. We are talking about the sculptures and bas-reliefs from the Parthenon and other classical Greek temples on the Acropolis in Athens that were brought to England in the early 1800s. Greece claims ownership, while England responds that they were legitimately acquired. Pending a solution, it was decided to make replicas, which will meanwhile allow the enjoyment of an artistic heritage dating back to 447 BC. In general, we can say that working with world-class artists, such as Jeff Koons, confirms to us on a daily basis the high level of quality and reliability of our system, which is capable of producing works that were previously impossible, especially because of the timeframes required in modern society.

3DN: Any Final Words for Our Readers?

The design philosophy of the ROBOTOR project does not involve violent actions on the material but favors a “gentle” approach by milling the material with diamond bits of progressively finer size. We also use composite materials obtained by recycling processing waste, thus espousing sustainable solutions and ushering in a new era of stone processing. For more information on TorArt and ROBOTOR projects please visit our website HERE.

What do you think of ROBOTOR and TorArt’s many projects? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

All photo credits: Laura Veschi/ROBOTOR/TorArt