MedScan3D Talks Creating Customized Anatomical Models Using 3D Printing

Surgical planning has come a long way in recent years, thanks in particular to new technologies used in the medical sector. Practitioners can now rely on digital tools to visualize pathologies in 3D, all in a personalized way to improve surgical outcomes. In addition to these tools, additive manufacturing plays a key role in the medical sector, and more specifically in planning. In particular, it enables tailor-made anatomical models to be designed from the patient’s CT scan, so that the surgeon can visualize, touch and train. Among the companies designing these models is MedScan3D. The company offers a wide range of 3D-printed products that not only improve surgical procedures, but also educate healthcare professionals and future doctors. We caught up with founder and CEO Jacqui O’Connor to find out more about these devices and how additive manufacturing is used.

3DN: Could you introduce yourself?

My name is Jacqui O’ Connor and I am the founder and CEO of MedScan3D. I have a 1st class honors degree in Chemistry and a master’s in biomedical engineering. I am skilled in research and development of biomaterials & medical devices and extensive clinical experience in the healthcare sector. I am a member of network Ireland and involved in female STEM support. At MedScan3D we utilize additive manufacturing to create patient specific and clinically relevant anatomical models for surgical planning and medical device testing.

Jacqui O’Connor

3DN: What is MedScan3D ?

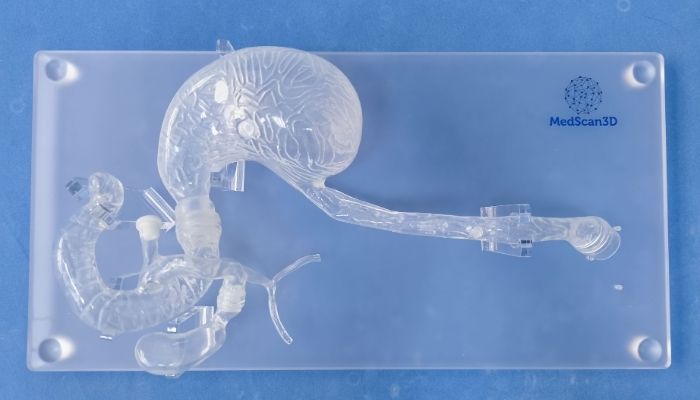

At MedScan3D, we specialize in 3D printing highly accurate patient-specific 3D anatomical models from CT, MRI and CBCT scans. Our target user is any healthcare professionals, such as cardiologists, oncologists, surgeons – placing real anatomy in the hands of healthcare professionals reduce the patient’s risk and a more successful outcome is likely, with less unexpected issues arising in the theater setting. These models can also be used for educational purposes for the team and for the patient in question.

Our models are not just for surgical planning, they are also used by research engineers to provide test models for their medical devices. These medical models can be made in a variety of materials for applications in medical device prototyping and testing. Customizable medical models to suit a specific area which will optimize their testing procedures at all stages of device development. Developing the right testing model is of the utmost importance for getting an implant to its most optimal stage. This in turn will provide the surgeon with the best device for treating the patient in question.

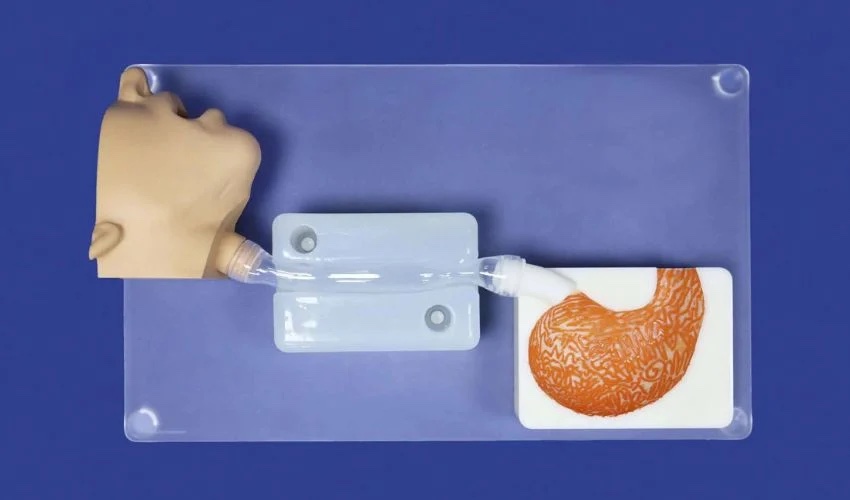

This model is designed for endoscopic retrograde cholangiopancreatography.

MedScan3D streamlines what is normally a complicated process and provides a full turnkey solution, all in house. This provides a quick turnaround of customizable models with no limitations – which meets the demands of fast-paced R&D teams. We pride ourselves on our consultancy basis and providing an extension to the R&D team.

3DN: Which 3D printing processes do you use? What about materials?

At MedScan3D, we use Material Jetting wherein droplets of liquid resin are sprayed onto a platform and cured under UV light after each layer. On the materials side, we use different types of resin:

- Tissue mimicking materials that simulate the mechanical properties of soft tissue.

- Silicone material with varying shore hardness.

- For rigid fixtures, either polycarbonate or acrylic-like materials.

3DN: What are the main benefits of using AM in the medical sector? What about specifically for MedScan3D?

I see several advantages in using additive manufacturing:

- It enables physical reconstruction of patient scans to provide an actual 3D model rather than relying solely on images.

- It offers rapid prototyping solutions to determine appropriate devices and implants before starting a procedure.

- It improves procedure planning through the use of patient-specific models.

- It facilitates communication with patients.

Different 3D-printed aortic valve models

3DN: Where do you see medical additive manufacturing in the 10 years?

I feel like the scope for AM in the medical sector is extremely large and untapped. At MedScan3D we want to be part of the bigger picture when it comes to device testing on anatomical models. Now we can bring patient specific data to bench testing which allows surgeons to get real feedback about the device they are going to use on an exact patient. The advancements in bioprinting is extremely exciting and the capability to now replaced machined aluminum parts with 3D printed parts which perform the same.

3DN: Any last words for our readers?

As a female woman in a male dominated space, I would like to encourage young women to take an interest in STEM at an early age and that it is a fulfilling sector where you can mix logical mathematics with creative design. Although the AM industry is a very male-dominated sector right now, that should only encourage women in STEM to be at the forefront and set the standards for the next generation coming behind you. Always be on the look out to connect with other females that will inspire and support you on your journey, having a group to share the ups and downs will motivate you to continue your path to success and never let anyone tell you that you cannot do anything you set your mind to. You can find out more about MedScan3D HERE.

What do you think of MedScan3D? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: MedScan3D