Medical Application of the Month: Discovering Micro 3D Printing

How can micro 3D printing technology revolutionize the medical sector and advance research? Can it be used to create medical devices, treatments for various forms of disease, or even functional tissues and organs? Boston Micro Fabrication is asking itself all these questions and has joined a program led by the University of Nottingham, specifically its Center for Additive Manufacturing. The “Dial Up” project is funded by an EPSRC grant and aims to “standardize 3D printing in medical technology and life science applications.” BMF’s micro-printing technology is currently being used to develop various medical applications: intestinal patches to combat certain chronic diseases, microstructures to control cell phenotype, etc.

The benefits of additive manufacturing for the medical sector need no further introduction. Healthcare professionals are increasingly interested in this technology, which enables them to develop tailor-made devices and improve their tools or even their surgical training aids, for example. Depending on the technology used, it also enables high levels of precision and resolution, mimicking a micro-injection molded part. This is one of the added values of Boston Micro Fabrication’s micro-stereolithography technology. It offers microprinting solutions that are repeatable, precise and accurate – resolution can reach 2 microns. By relying on its 3D printers, it is possible to achieve very fine features and complex geometries, often sought-after in a sector as demanding as healthcare.

Professors Ricky Wildman and Felicity Rose from the University of Nottingham’s Biodiscovery Institute with BMF’s CEO John Kawola

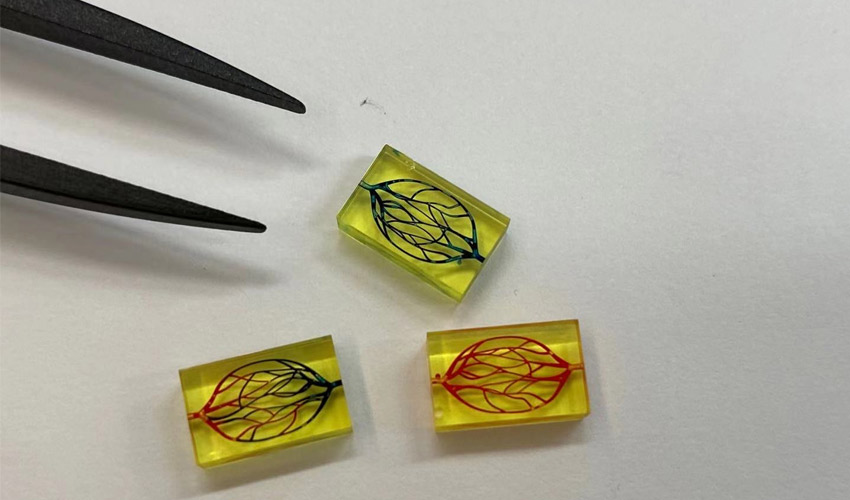

In this context, the Dial Up project tests BMF’s micro-printing process and develops several concrete applications for the medical sector. The first concern is intestinal diseases: the aim is to create a patch capable of regenerating inflamed intestinal tissue. The patch is to be placed inside the patient’s body and must, therefore, be non-intrusive. In addition, the materials used must have suitable characteristics for the body’s own cells. These constraints cannot be overcome by all printing technologies.

In addition to this project, the researchers are developing micro-architectures that could be able to control and direct the phenotype of the cells, i.e. “the set of anatomical, physiological and antigenic characters that enable each type of bacterium or virus to be identified and classified.” This would promote the creation of microparticles that could lead stem cells to the desired area.

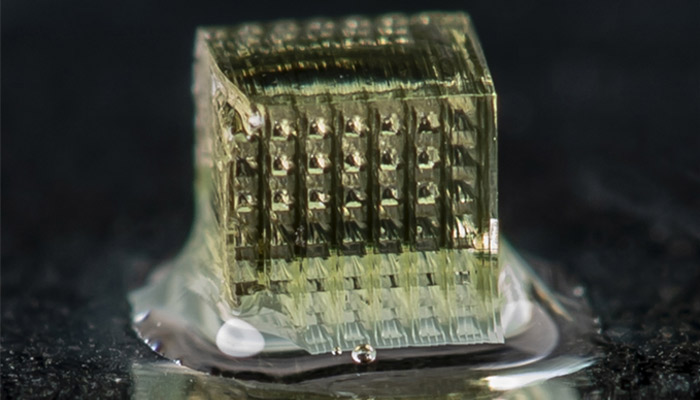

3D printed reactor core for synthesizing small organic molecules. Reactants flow into the structure, where entrapped enzymes catalyze their reaction into useful product molecules. BMF’s micro 3D printing technology was used to create the functional hydrogel (credits: University of Nottingham’s Biodiscovery Institute)

Finally, the research team is looking into the problem of rejecting medical devices from the body. Today, too many medical devices are not properly integrated into the human body, with potentially serious consequences for the patient. During their research, the team realized that the materials of these implantable devices, as well as the physical surface patterns – or topographies – exerted a major influence on how the device was accepted. BMF technology is used to scale up the results obtained and enable the creation of implantable medical devices for which the materials and topographies have been tested and validated.

The research project carried out by the English university is in fact an approach to finding new methods of manufacturing tailor-made medical devices to improve healthcare. Ultimately, the researchers hope to draw on artificial intelligence and machine learning to gather as much data as possible and devise more efficient models for their manufacturing processes.

Want to find out more about Boston Micro Fabrication’s micro 3D printing technology? Click HERE. What do you think of the use of micro 3D printing in the treatment of chronic diseases? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Credits cover picture: Boston Micro Fabrication