Measurement In Real Time: Researchers Develop 3D-Printed Insoles

Did you know, the American Podiatric Medical Association (APMA) surveyed 1,000 US adults and found that 77% of Americans have experienced foot pain? Now, 3D-printed insoles are set to provide relief. The new development by researchers at the Swiss Federal Institute of Technology Zurich (ETH Zürich), Federal Institute of Technology in Lausanne (EPFL), and the Federal Laboratory for Materials Testing and Research (Empa) is designed to allow patients and athletes to track the progress of their therapy and training. The insole is equipped with integrated sensors that are designed to measure the sole pressure directly from the shoe, the team says in their scientific publication.

Whether in sports to optimize one’s own performance or to minimize foot-related complaints in everyday life – more and more people are benefiting from custom-made insoles. In most cases, however, the process of sole production takes a lot of time. A personal pressure profile of the feet must first be created for each customer. To do this, customers must step barefoot onto a pressure-sensitive mat so that the footprint can be recorded. The insole is then created by hand based on the individual pressure profile. This not only costs time, but is also limited to the performing facility.

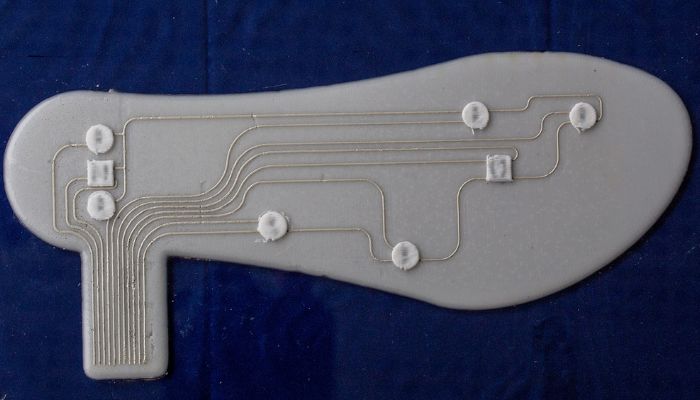

3D printed insole with conductive tracks and sensors made of piezoelectric elements

The insoles, made using additive manufacturing, record the pressure patterns in the shoe in real-time, so the activity the wearer is performing becomes apparent – whether “someone is walking, running, climbing stairs or even carrying a heavy load on their back. In which case, the pressure shifts more to the heel,” says Gilberto Siqueira, co-project leader and senior research assistant at Empa and the Laboratory for Complex Materials at ETH Zurich. The sensors, AKA piezo elements, transform mechanical pressure into electrical signals, measuring both regular and shear forces.

Printing Layers From Different Materials

3D printing the insoles is simple and can be done in just one pass in the extruder. Moreover, the research team specially developed the materials used for this purpose. The soles are manufactured according to a layering system. The base consists of a material mixture of cellulose nanoparticles and silicone. First, the conductive tracks are printed onto the base as the first layer using silver conductive ink. Then, sensors printed from soot-containing ink are integrated in exactly the places where the pressure of the sole of the foot is expected to be highest. The final layer consists of a silicone coating to prevent damage to the conductor paths and sensors. Finally, the surface of the silicon layer is treated with hot plasma – so that the different material layers adhere firmly to each other.

Once enough data has been collected; it can be read out via a cable connection using an interface in the sole. Currently, the developers are still working on establishing a wireless connection for future use. The sole is to be used in sports and physiotherapy. Users can track their progress based on their measurements and, if necessary, create perfectly adapted training plans. Customers will also be able to purchase permanent 3D-printed shoe insoles. These will be provided with hard and soft variations, using precise and individual measurement data to guarantee the wearer optimal progress in the future.

What do you think of the 3D printed insoles? Would you test them out? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Jonathan Blutinger/Columbia Engineering