The new McLaren 720S includes 3D printed parts

One of the greatest advances we have seen in the additive manufacturing industry is the variety of applications it finds in the automotive industry. The customization of high-end vehicles is very important to many potential buyers in order to acquire a vehicle that is tailored to their needs. In the past, parts manufacturing in this area was subject to many restrictions, but with technological advancements, quality has increased and the production time of 3D printed parts has been reduced. The McLaren 720S is just one example of many cars that are related to additive manufacturing.

The McLaren 720S was unveiled this month, and it was clear that some of the parts were 3D printed. The vehicle development was made possible thanks to technology from 1016 Industries, a Miami-based company of engineers dedicated to the development of the sports car. In partnership with Abushi, the project took 4 months to design and produce the main elements. The sports car has already been launched on the market and experts now expect that it will have a lasting impact on the automotive industry and will also focus on large format 3D printing.

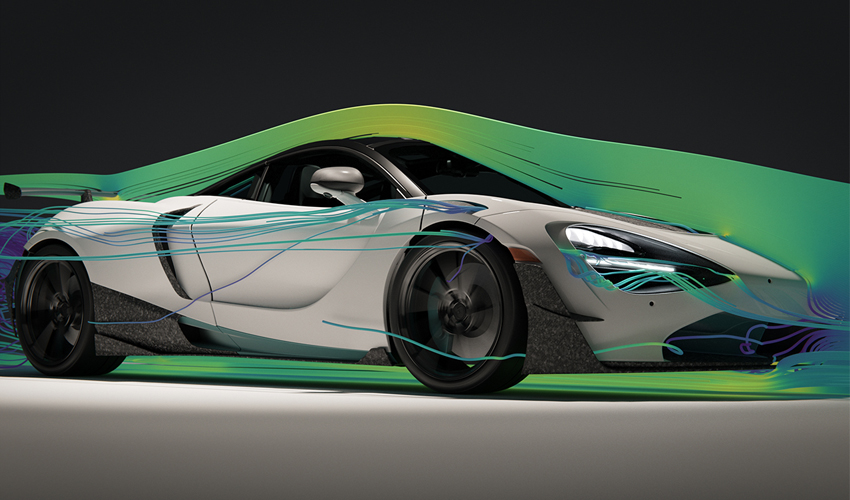

The majority of the body parts were produced using 3D printing | Credits: 1016 Industries

The 3D printed parts of the McLaren 720S

The production of body parts is often an extremely lengthy process. The researchers took this on board and used a resin 3D printer with a maximum construction volume of 1.2 x 1.5 x 1.8 meters. This made it possible to print all the individual parts within 140 hours. The parts were designed using Computational Fluid Dynamics (CFD) from 1016 Industries to achieve optimal ergonomics. This plays a particularly important role in sports cars, as it has a direct impact on the performance of the car. For the aerodynamic parts, many original parts have been replaced by 3D printed parts, including the rear wing, hood, outer door wings and bumper.

Additive manufacturing has played a key role in the development as well as the finished end part and has proven its cost efficiency, at least according to Peter Northrop, founder of 1016 Industries: “Our approach to this project was to explore how we can use 3D printing in the automotive world, and the results achieved with these McLaren 720S parts are impressive. The 3D printing process has not only allowed us to produce faster and more efficiently, but has also improved quality. 3D printing has enabled us to make every part at 1016 Industries more accurate, with every part printed at full scale to validate our CAD and CFD work.”

Credits: 1016 Industries

The American company is aiming to use 3D printing to tailor future models to the wishes and needs of customers. This would represent a major innovation for the automotive industry. You can find more information HERE.

What do you think of the new McLaren? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!