The Mass Spectrometer Filter 3D Printed in Just a Few Hours

At MIT, a team of researchers led by Fernando Velásquez-García has developed a 3D printed filter for a mass spectrometer. This device, designed to detect molecular structures by measuring their mass, has traditionally been bulky, fragile and, because of its size, difficult to deploy in certain areas. Using photopolymerization and a heat-resistant glass-ceramic resin, they succeeded in producing the device’s filter, more commonly known as a quadrupole. Thanks to additive manufacturing, the team were able to considerably reduce the filter’s production time, cost and weight.

Mass spectrometry was developed in the 1900s and was originally used to identify and separate the isotopes of a chemical element. Since then, the technique has been perfected and is now used in many scientific fields, including chemistry, physics, biology and geology. A spectrometer is made up of four parts, including the analyzer capable of separating the ions, either with a high-resolution or low-resolution analyzer. In the latter case, a quadrupole is used, i.e. a component that enables energy transfer. This is the component designed by additive manufacturing in just a few hours and for just a few dollars, compared with the traditional weeks and thousands of dollars.

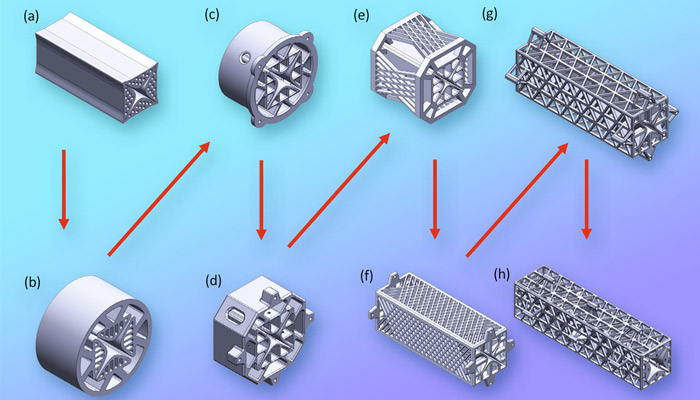

Additive manufacturing makes it possible to imagine a wide range of shapes and iterations

A 3D Printed Spectrometer Filter

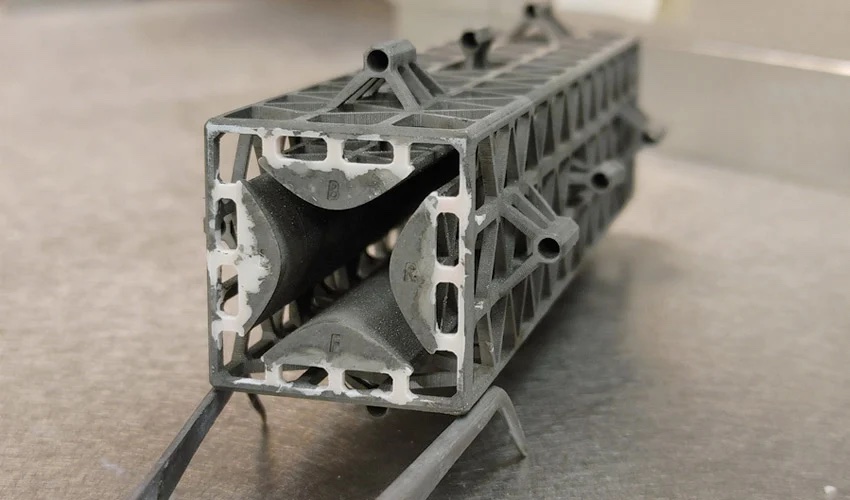

The component is said to have been 3D printed using a resin machine: the team explains that they used a glass-ceramic resin cured layer by layer by several LEDs. The 3D printer produces the miniaturized quadrupole in a single operation, eliminating the assembly steps that can lead to defects and thus reduce the quality of the component.

Fernando Velásquez-García noted: “We are not the first ones to try to do this. But we are the first ones who succeeded at doing this. There are other miniaturized quadrupole filters, but they are not comparable with professional-grade mass filters. There are a lot of possibilities for this hardware if the size and cost could be smaller without adversely affecting the performance.”

Using additive manufacturing offered many advantages to the MIT team, as explained above. It has also made it possible to reduce the size of the mass spectrometer, thus widening the field of possibilities. The team explains that they will be able to use it in more remote areas and carry out analyses more quickly and efficiently. Examples include the rainforest or space, where the device could be used to analyze atmospheric chemicals.

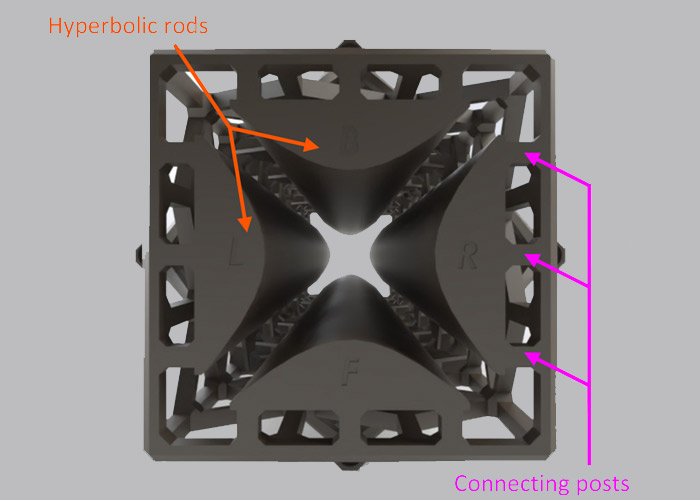

What’s more, with 3D printing offering more possibilities in terms of shapes and geometries, the team came up with another design for their quadrupoles. They designed a device with hyperbolic rods, ideal for mass filtering. Traditionally, these rods are rounded, which can affect spectrometer performance. Next, the researchers placed lattice structures around the rods to maximize their strength and durability. Finally, a post-treatment step made the rods conductive: thanks to electroplating, a thin film of metal was safely applied. The result? Quadrupoles around 12 cm long, four times less dense than stainless steel filters.

Researchers design a quadrupole with hyperbolic rods

In the future, the team would like to extend the filters to enable more precise analyses. Fernando Velásquez-García concludes: “Our vision is to make a mass spectrometer where all the key components can be 3D printed, contributing to a device with much less weight and cost without sacrificing performance. There is still a lot of work to do, but this is a great start.” You can find more information in MIT’s official press release HERE.

What do you think of this 3D printed spectrometer? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Photo Credits: MIT