#3Dstartup: Marklix produces spare parts thanks to 3D printing

While additive manufacturing allows for faster production of end use parts, it is also very popular for the design of spare parts. These are sometimes very expensive to get due to their scarcity – the automotive sector and vintage cars come to mind in particular – it’s also rather time-consuming to find these parts, manufacture and ship them. Many consumers are therefore discouraged and will tend to throw away their device when it no longer works: this is where Marklix comes in, the online platform allows you to find your spare part and receive it quickly thanks to 3D printing. Thanks to this production method, the young startup can produce small batches at lower costs, offer local production and imagine many spare parts, whether for household appliances or cars for example. We were able to meet Pierre-Jacques Lyon, one of the co-founders of Marklix, to find out more about how the platform works and his ambitions.

3DN: Can you introduce yourself and your link with 3D printing?

My name is Pierre-Jacques Lyon and I am the co-founder of Marklix. I have an engineering background in applied physics. I trained in Canada at the École Polytechnique de Montréal, and in Switzerland at the École Polytechnique Fédérale de Lausanne. I then had the chance to do my final year internship at the CEA in Cadarache and to work as an R&D engineer on the superconductor coils of the ITER fusion reactor project.

My first contact with a 3D printer dates back to my studies at Polytechnique Montréal. We had a lot of design projects to carry out as a group. 3D printing was then an essential tool to facilitate our design and prototyping work. Whether it was to design measuring tools or test benches. In parallel with my studies, entrepreneur at heart, we created with friends a company called D4print. Initially, our goal was to offer printing services in FDM, which led us to the manufacture of our machine and finally the desire to market this beautiful machine. The project was eventually aborted when it was brought to market, due to a lack of capital and the demotivation of some of us to become full-time entrepreneurs. This adventure taught me a lot about additive manufacturing: Its market, its players and its technologies.

3DN: Why did you create Marklix?

Marklix stems from an awareness we had during the development of D4Print. The lack of public awareness of 3D printing makes this technology difficult to access. Our initial desire was to create, using our knowledge of modeling, a library of 3D files linking manufacturer brands and individuals. Marklix is revolutionising the system by bringing quality 3D printing to the widest possible audience. We then realised that 3D printing of spare parts, on demand, could have a positive impact on the repair of many devices. We then decided to focus solely on the repair part and make our contribution in the fight against obsolescence. It is these successive ideas that will bring Marklix to life.

3DN: Can you explain how the platform works?

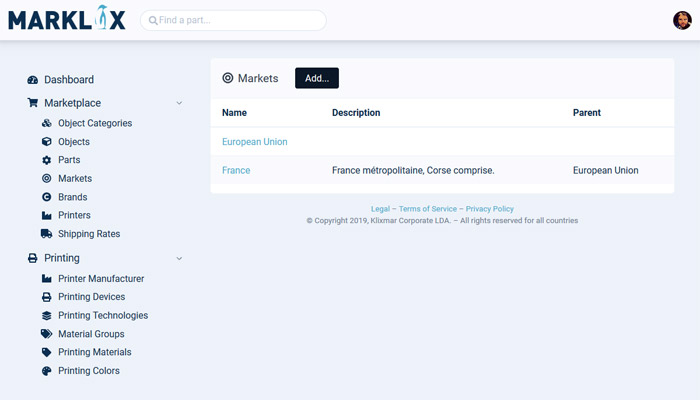

Marklix is the union of 3 words: “Market”, “Library” and “Exchange”. In other words, Marklix.com is a Marketplace that connects any 3D file designer (Markers, manufacturers and industrials), 3D printing providers with consumers and repairers with a need for spare parts. For the consumer, Marklix is a classic Marketplace with similar functionality to Amazon. All you have to do is search for the part number of your part and order it. We have also set up a program called “Ask for a part” that allows you to request a part when it is not yet in our catalogue. All you have to do is fill out a questionnaire and send the broken part, when it is in your possession, so that we can have it reproduced.

In order to satisfy our customers, we have set ourselves a few requirements: In a local production process, the part is automatically entrusted to a service provider located in the country where the order comes from. Furthermore, we only work with industrial service providers to produce Marklix parts and our makers are professionals. We have also created a series of tools and a “DashBoard” administration area so that our service providers, 3D printers and makers, can automatically interact with the Marketplace and our management systems. Today we are still developing new tools to check the feasibility of a part by additive manufacturing.

3DN: What 3D technologies are used?

In France, our production is carried out by Silex3D in the Rhône-Alpes region. This company benefits from a solid experience and meets the most stringent industrial standards. The vast majority of our parts will be produced by selective laser sintering (SLS) in PA12 on EOS or HP Multi-Jet printers. Some of our references will also be manufactured by material extrusion (FDM) and exceptionally by stereolithography (SLA). We associate to each reference the technology and the most suitable material for its use, taking into account its environment and its mode of use. Again in a concern of simplicity and quality for the consumer.

Marklix uses EOS’ technology

3DN: What kind of spare parts do you offer?

Our catalogue today includes a wide variety of types of parts with a high concentration for small and large household appliances. There are also a few parts dedicated to the automotive or furniture industry. We want Marklix to be a means of repair for every Marklix consumer. That’s why we need to cover a wide range of product categories while focusing on frequently breaking parts. Via the “Ask for a part” programme we offer the possibility of sending spare parts: our customers can then directly decide on their needs for spare parts.

3DN: Why rely on 3D printing to produce spare parts?

3D printing allows on-demand manufacturing at a substantially constant and predictable cost. It is an excellent means of production for small production runs that also remains agile and quickly deployable in different countries. Additive manufacturing also offers a wide variety of materials and technologies allowing the manufacture of a wide range of parts for different uses.

3DN: A last word for our readers?

We look forward to hearing from you at Marklix.com and to your feedback! If you are a professional in the additive manufacturing industry, please feel free to contact us directly from our site.

What do you think of Marklix? You can read about our last #3Dstartup HERE. Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!