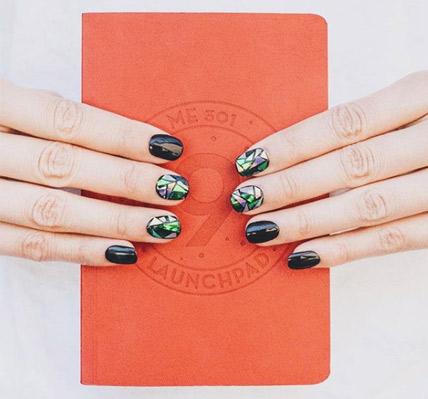

Mani.me and their 3D printed Nails; the future of manicures?

The technologies of additive manufacturing’s impacts is constantly brought to different sectors from food to vehicles, through fashion and reaching consumer products. However, believe it or not, 3D printing technologies have gone into manicures… Or at least that is the proposal of Mani.me, a company dedicated to the manufacturing of fully 3D printed nails. Bringing the custom made and customised aspect to a new level in nail art.

The operation of personalised manicures is simple. You only have to send photographs of your hands through your application. With this information the team of Mani.me is able to develop the solution with 3D printed nails. It’s the fastest way and quit a lot simpler than any other traditional technique. To learn more about this innovative project we have spoken with Jooyeon Song, co-founder of Mani.me, and one of our selected as entrepreneurs in 3D printing under 30 years.

3DN: Can you introduce yourself and your link with 3D printing?

Hello, my name is Jooyeon Song and I am the Co-founder of Mani.me. I first discovered 3D printing when I was 19, while working for Hyundai Engineering Center in India during my gap year at University. When I worked as an IT assistant in the center, and I was often mesmerised by how designers bring their project to life, from their head to a real object particularly thanks to 3D printing. And I started to learn about CAD modeling and studied 3D printing tech since then.

Founders of Mani.me: Jooyeon & David Miro Llopis

My business partner David Miro Llopis studied industrial engineering at CentraleSupelec in Paris. His graduation thesis was on the generation of plasma: he designed and 3D printed a plasma reactor. On top of that, he’s passionate about creating products especially with new technologies.

3DN: How did the idea of creating Mani.me come about?

As you can imagine, I love manicures. However, when I worked as a management consultant, I always felt frustrated because it was very difficult for me to find time to go to the nail salon. I didn’t like committing 2-3 hours of my time from an already busy schedule. I tried getting it done by myself at home, I bought a bunch of manicure polish bottles. However, painting my own nails by myself resulted in terrible looking nails (especially on my dominant hand), many unused polish bottles, as well as a messy room.

When I was working in Finland, my sister sent me a fake nail set that was popular in Korea. But as they were mass produced for the “average size”, they did not look good, and most importantly I felt really uncomfortable. It didn’t give me a feeling of being well “put together”. Then I thought, ready-to-use manicures should be tailor-fitted and soon after found out that I can connect the dots with my 3D printing passion.

3DN: What are the different steps to create 3D printed nails?

It starts with getting a pictures of customer’s hands. We’ve developed our photogrammetry software, which can transfer 2D image information into a 3D model, generating a unique model for each nail.

Our customers takes a few pictures on our app, and we build a nail model in our software. With the 3D model as a base, we can generate a 3D pattern file for each design our customer selects on our gallery and then 3D print it!

From a customer perspective:

- Browse our gallery to find the trendiest colors and the best designers from all over the world.

- Get fitted (only the first time) by taking 5 pictures form your phone camera.

- Check-out a single set of nails or join a subscription plan where you can get additional sets for many occasions.

We are still finalizing our patent for the technology we have developed. We’ll tell you more about the materials, the software and every step of the process once everything is settled!

3DN: How do you see the future of additive manufacturing in the cosmetic market?

When I first discovered 3D printing in 2011, 3D printers were only for rapid prototyping as they had limited printing speed and material availability. Let’s say, at least for me, it was hard to imagine printing “shoes” from a 3D printer. But now, we see that 3D printers keep evolving, offering scale production capabilities in several industries: Aerospace, Automotive, Health and Fashion.

We believe that this constantly evolving 3D printing tech will reshape custom manufacturing. And guess which industry needs custom manufacturing? The cosmetics market for sure! Every woman and every man is special. Their skin color, preference, occasion, skin condition, and nail size. We now have millions of choices in terms of cosmetic product availability, but nobody is sure if she/he has chosen the right product for themselves. This issue very much applies to the cosmetics manufacturers. Along with typical supply chain issues of sustainability and quality, the cosmetics industry has to keep up with the quickly changing demands of customers, stock a wide range of products to suit all consumers, and still avoid wastage from unsold inventory.

Cosmetics manufacturing as we know it will never be the same. And it will be very exciting to be part of this transformation – how additive manufacturing can innovate this industry.

3DN: Do you have some final words for our readers?

Your nail fashion can be as changeable as your shoes with Mani.me & 3D printing! I hope to see many other interesting applications of this technology. For more information about Mani.me’s 3D printed nails, you can visit the official website here.

What do you think of the the 3D printed nails from Mani.me? Let us know in a comment below or on our Facebook and Twitter pages! And remember to sign up for our free weekly Newsletter, to get all the latest news in 3D printing send straight to your inbox!