MakerBot expands technical materials compatible with its machines

The American manufacturer MakerBot made its comeback last year by presenting a new 3D printer called METHOD, it is a desktop machine, yet a professional solution. During Formnext 2019, the company launched an experimental extruder designed by MakerBot LABS and a METHOD materials development program. The manufacturer’s objective is to expand the technical materials compatible with its machines today so that the user can go further in applications, especially industrial ones. The 3D printer manufacturer has already chosen material manufacturers to partner with: KIMYA, Jabil, Polymaker and Mitsubishi Chemical.

When we talk about FDM 3D printing, it is often the material that makes the difference, especially on more professional machines. In recent years, there has been a real growth of polymers available on the additive manufacturing market, with more companies seeking solutions that are adapted to their requirements. This is why high-performance thermoplastics have exploded, but also composite materials (carbon fibre, glass fibre, etc.), which are lighter but very resistant. We also notice that machine manufacturers are more attentive to creating partnerships with material manufacturers in order to certify several filaments on their 3D printers, thus offering the user a guarantee of quality and a better experience, such as Ultimaker, Raise3D and more recently MakerBot.

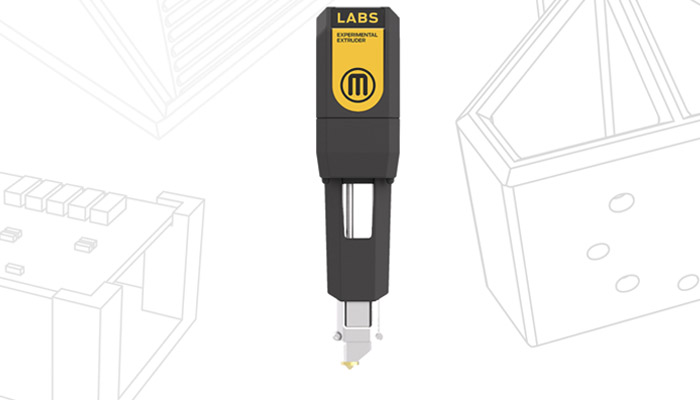

MakerBot’s experimental extruder | Credits: MakerBot Labs

An experimental extruder for the METHOD and METHOD X

MakerBot LABS has developed a new extruder with a new hot end to easily change the nozzles, allowing a wider range of compatible materials. In the future, the solution should be fully customizable, with extensive printing settings supported by MakerBot Print software. Several nozzle models are therefore available: a standard 0.4 mm, a brass 0.6 mm for flexible materials, and a stainless steel 0.6 mm for abrasive materials.

Nadav Goshen, CEO of MakerBot adds: “We know that many of our customers want to experiment with different materials to explore new 3D printing applications. With the MakerBot LABS experimental extruder, we are adding more advanced customization settings, which allow users and our development partners to print and certify a wider range of technical materials for the METHOD platform.” This new experimental extruder is expected to be available in December 2019 as part of a beta program open to MakerBot customers and its few new users.

Credits: MakerBot Labs

Strategic partnerships for MakerBot

In order to offer its customers certified solutions, MakerBot has created its METHOD materials development program by partnering with several materials manufacturers including KIMYA, Polymaker, Jabil and Mitsubishi Chemicals – others will be announced in the coming months. 7 filaments have so far been certified for use on METHOD and METHOD X.

The new MakerBot partners all agree that technical materials are the future of additive manufacturing, which is more production-oriented than rapid prototyping. Dick C. Hoogerdijk, Director of Marketing and Business Development at Mitsubishi Chemical, continues: “Mitsubishi Chemical is constantly working to create new technical material solutions for industrial 3D printing and is very proud to cooperate with MakerBot, one of the leading manufacturers of high-end printers.” We hope to see these partnerships grow and test the new extruder in our 3Dnatives Lab!

What do you think of these partnerships? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter to receive all of the latest news about 3D printing straight to your inbox!