The main highlights of In3Dustry 2018

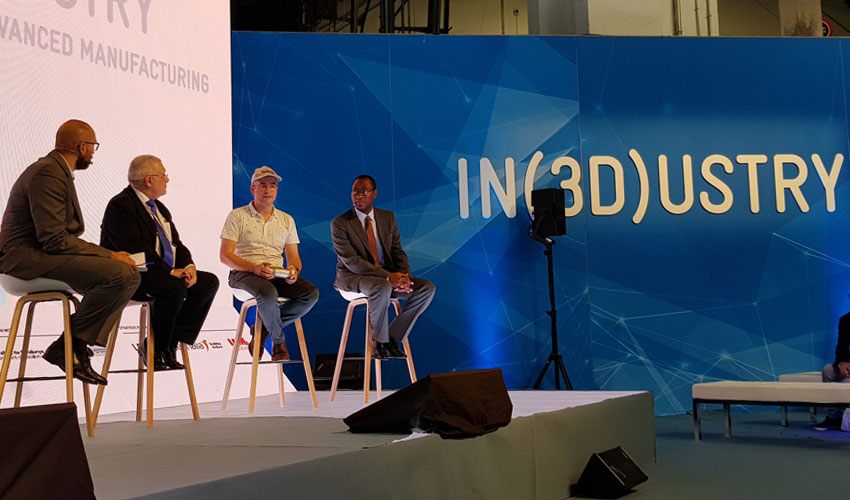

In3Dustry 2018 finished up last Thursday. It was its third edition and reaffirmed its position as one of the main events specialised in additive manufacturing in Europe. This year, as in 2017, it was part of the Barcelona Industry Week, with more than 550 companies, 700 speakers and 25,000 professionals. The goal? To continuously invite more actors, brands and professionals to discover what additive manufacturing technologies can bring to the different sectors, so they have not missed the innovations at In3Dustry; From Needs to Solutions.

After the event Salvador Tasqué, Director of Own Business of Fira Barcelona, commented: “This edition has been marked by a high level of interaction and great activity, showing that the digital transformation is no longer just an idea of the future but a reality“.

For this reason, multiple companies took advantage of the opportunity to meet some of the most important players in 3D printing and present their technological innovations and projects being developed. To keep ahead of what will come in the coming months we have made a brief summary with the main developments.

The main highlights of In3Dustry 2018

HP University

This year for the first time the American giant HP approached the subject of training in 3D printing. They presented their “HP University”, undoubtedly one of the main novelties of In3Dustry. An informative space in which presentations of experts from the brand’s developments and the benefits of the digital transformation of the industry were explained.

“We want to present real cases and practical guides so that companies can take advantage of the potential of this new way of manufacturing“, assured the sales director of HP’s 3D Printing department in Spain and Portugal, Jaume Homs.

The first edition of this project included presentations on the possibilities of additive manufacturing, analysis on the new printing materials that are currently on the market, 3D technologies in robotics, and what is most interesting for young people, learning to design within the 3D printing sector.

3D Factory Incubator and DFactory of the CZFB

During In3Dustry 2018 the Consorci de la Zona Franca de Barcelona (CZFB) has presented two major projects for the additive manufacturing industry. On the one hand, there is the 3DFactory Incubator, a European incubator for additive manufacturing projects. More than 600m2 in which will be areas of co-working, training and laboratories equipped with 3D printers. This is expected to boost the transformation of small and medium enterprises to industry 4.0. Its goal is to benefit more than 100 companies over a period of five years.

The other project presented by the CZFB has been DFactory 4.0, a hub area in which the goal is to create an ecosystem of industrial companies with advanced digital technology. The development with these advancements with the Zona Franca expects to have 71,000 m 2 of space for the economy 4.0.

It is expected that one of the projects will be developed in the Free Zone of Barcelona

Eurecat and its three new 3D printing technologies

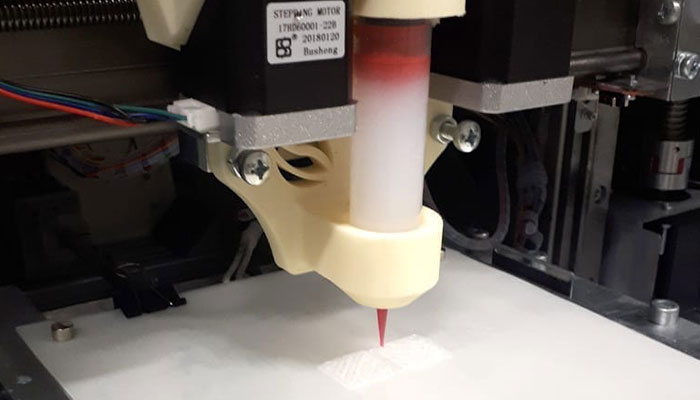

Eurecat is the Technological Center of Catalonia. During the fair they presented three new 3D printing technologies. The first one is specially designed for the biomedical sector. It will help the realisation of customised prosthesis, with it’s based of silicone as a raw material for manufacturing. The other two allow the development of models thanks to sheet metal deformation layer by layer with the calculation of the structural behaviour of the piece. This helps determine what will be the best material and manufacturing process for each of the pieces.

“The three technologies are registered in the so-called Industry 4.0 , because they allow the control of production and quality and the viewing of the pieces during production, as well as the production of small and customized series, with materials as different as silicone, the steel sheet and the polymers “, stated Myriam García-Berro, Eurecat’s Director of Technology and Transfer.

The 3D printer developed for the printing of silicone is a pioneer in the printing of monocomponents or biocomponents, where the material can be adapted to the needs of each project.

3D printing technology based on silicone

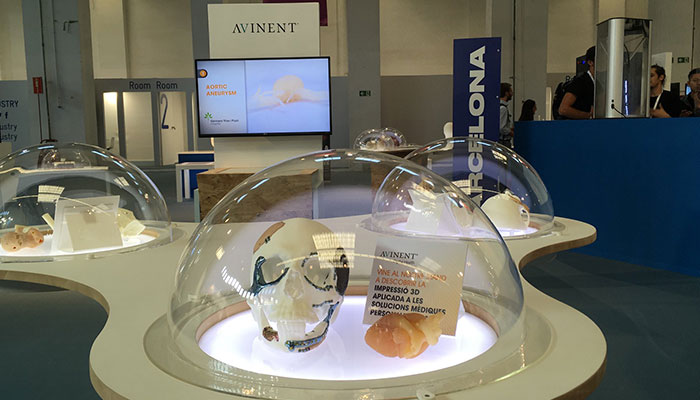

Avinent and the evolution of implantology

Avinent was one of the main protagonists of the fair, and without a doubt one of the ones that showed the most outstanding novelties at In3Dustry. The company specialising in implantology has turned a corner by adding additive manufacturing technologies to its production. For them the arrival of 3D printing has marked the difference between before and after. In this latest edition of the fair they presented their new multi-material system together with Stratasys for the development of anatomical medical models, which will allow the planning of the surgeries before their realisation.

Among the different talks given by Albert Giralt, CEO of Avinent, special emphasis was placed on the importance of incorporating additive manufacturing in hospitals and clinical centers. To give greater weight to their statements, they presented, together with the Althaia Foundation, 12 success stories on the use of 3D printing in the medical sector.

Avinent showed the importance of the use of 3D printing in the medical sector

What do you think about the innovations of In3Dustry 2018? Let us know your thoughts on the in3dustry 2018 in a comment below or on our Facebook and Twitter pages! And remember to sign up for our free weekly Newsletter, to get all the latest news in 3D printing send straight to your inbox!