Machine Learning: The Importance of Artificial Intelligence for Additive Manufacturing

For many companies, digitization and automation are the keys to the further development of additive manufacturing. Thus, more and more manufacturers are relying on cloud-based solutions and integrating various algorithms into their 3D printing solutions in order to exploit the full potential of the technology. As a digital process itself, 3D printing is part of Industry 4.0 and thus an important component of an era in which artificial intelligence, such as machine learning, is increasingly being used to optimize the value chain. Artificial intelligence (AI) is able to process a large amount of complex data in a very short time, which is why it is becoming increasingly important as a decision maker. We explain what machine learning is and why this form of AI is helping to shape the future of additive manufacturing.

Machine Learning is a subcategory of AI and is defined as a system or software that uses algorithms to examine data and subsequently recognize patterns or determine solutions. Contrary to a widespread belief that machine learning is a newfangled phenomenon, it can be said that its beginnings date back to the 1940s, when the first researchers started to recreate the neurons of the brain with electrical circuits. In 1957, the Mark I Perceptron was the first major success in this field: the machine was able to classify input data independently. In doing so, the device learned from mistakes made in previous attempts, which improved the classification over time. Since then, the foundation was laid and researchers became fascinated by the possibilities and potential of the technology. In the meantime, we encounter artificial intelligence every day in all areas of life. From speech recognition to intelligent chatbots to personalized treatment plans, Machine Learning is being used in a variety of applications.

The Mark I Perceptron laid the foundation for machine learning.

Supervised vs. Unsupervised Machine Learning

Within the machine learning spectrum, it is important to distinguish between different methods and models. Not all machine learning is the same. For example, a distinction must be made between supervised and unsupervised machine learning. Supervised Machine Learning requires that categorized data (input data) and the target variable (output data) are available. From these, the model is derived, which then examines (new) uncategorized data and determines the target variable for these itself. This form of machine learning is used, for example, for predictions, e.g.: for forecasting maintenance intervals.

In Unsupervised Machine Learning, the opposite is true as a starting point. The software does not have a target variable (output data), but must recognize patterns or suggest solutions based on the input data. This type of Machine Learning is used, among other things, in marketing to identify customer segments, so-called “clustering”. But there are other differences. For example, there is still semi-supervised learning, which uses only a small amount of predefined data in a large amount of raw data to train the model, and reinforcement learning, in which the system learns itself based on predefined rules. Users must therefore choose the appropriate method based on the raw data and the target variable.

How is machine learning used in additive manufacturing?

As a digital production process, additive manufacturing benefits from the capabilities of machine learning. Since countless data are collected and processed (in real time) along the additive value chain, they can be used to analyze the ACTUAL state and subsequently redefine the TARGET state. In doing so, it is first important for companies to define which data is relevant at all. This decision depends in each case on the process used. The next step is to find and integrate the appropriate measurement tool for capturing the values before defining a suitable model or algorithm for data collection and processing. In this context, it is also important to understand that all steps along the additive value chain influence each other, which is why an isolated view is not expedient in most cases. For example, the design already influences the subsequent component quality and the desired component quality influences the design. For this reason, more and more companies are trying to offer a comprehensive software solution with which the advantages of artificial intelligence can be exploited in the best possible way for the additive manufacturing process.

Intelligent design

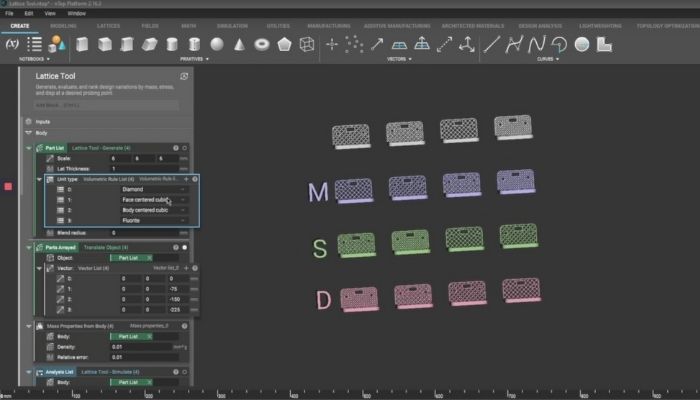

At the beginning of every 3D-printed component is a file, in most cases a CAD file. This is already where companies can benefit from artificial intelligence. For example, most software solutions on the market today already use AI to suggest intelligent design variants to users based on predefined variables. This process is known as generative design, among other things. Machine learning is also used for topology optimization. Many software solutions also make suggestions about production methods, materials and optimal use of installation space. This can save costs and produce parts not only more efficiently but also more sustainably.

The simulation tool of nTop software proposes several variants of a lattice structure and ranks them based on weight and mechanical performance (photo credits: nTopology)

Quality assurance

If the 3D printable file is already optimized, the focus might instead be on the 3D printing process used, the material quality and the component quality. Today, many manufacturers have already integrated cameras and sensors into their machines, which can track the print and sound an alarm or stop the print if necessary. In this step, it is important to know how the quality of the part is defined during printing in order to be able to define the required measurement values. It is also important to define which action should be performed by the machine at which threshold value. Today, some algorithms are already able to define these parameters independently and to further develop the model on the basis of data already collected. How this can look is best explained with a practical example.

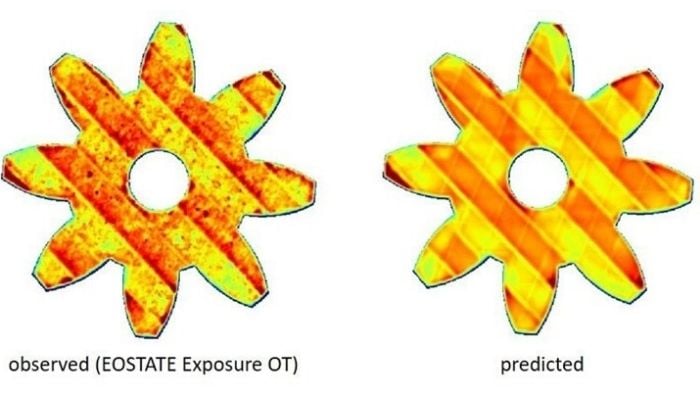

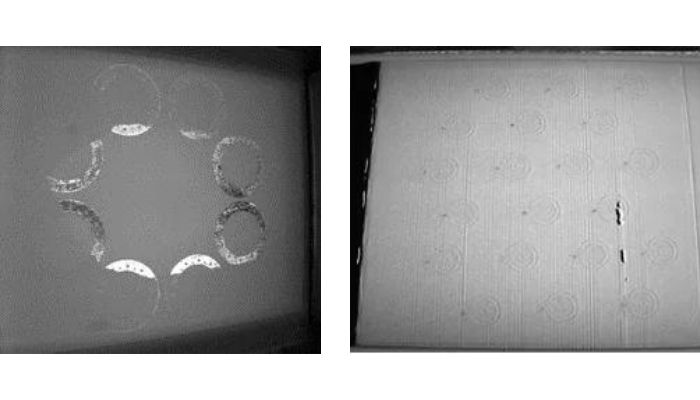

EOS has teamed up with NNAISENSE, a Swiss software provider, to develop a digital twin for the DMLS process. In the printing process, thermal images are captured from each printed layer using optical tomography (OT) and compared with the image predicted by the AI. This allows anomalies to be detected immediately and the printing process to be halted if necessary, resulting in material and cost savings. The model developed by NNAISENSE is a self-supervised deep learning strategy. Siemens highlights that quality assurance in additive manufacturing (AM) using artificial intelligence and machine learning can result in shortening the time from prototype to finished part and accelerating the efficiency of high-volume production. The company appreciates the camera integrated by EOS to monitor the individual print layers, because it can identify missing powder on the parts to be printed (left) or powder drops during recoating (right) in real time.

Left: Anomaly due to missing powder; Right: Error during recoating (photo credits: Siemens)

The quality of each coating is recorded as a numerical value and automatically evaluated. When this so-called severity score reaches a certain threshold, it can indicate a serious problem with the coating (as in the example above). The company says this simplifies optical inspections, as only critical layers need to be evaluated by an expert.

Further applications

AUTOMAT3D, PostProcess’s post-processing software, monitors key process factors in real time and responds autonomously to achieve the best possible finish on 3D-printed parts. To do this, the company uses data from hundreds of thousands of benchmark parts. In addition, AI is increasingly being used to automate and optimize workflows. Smart sensors are found in critical components, which are the measuring instrument of intelligent and preventive maintenance, or “predictive maintenance.” It is foreseeable that the use of machine learning for manufacturers’ production processes will continue to increase in the coming years. The global market for artificial intelligence and advanced machine learning is forecast to reach $471.39 billion by 2028 at a growth rate (CAGR) of 35.2%.

In your opinion, what potential does machine learning have for use in additive manufacturing? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Siemens

Awesome article on the basics of machine learning! But where is the machine learning for FFF/FDM failure detection? Failures such as layer shifts, warping, and nozzle blobs can cause damage to the printer increasing cost, delaying production, and requiring significant operator time to repair. So why don’t we have failure detection beyond basic spaghetti? This article provides the answer: DATA. to learn, the machine needs to see a lot of failures and figure out exactly why people think that is a failure. We are putting together a beta on the Automated Printing Community Discord to develop AI-driven failure detection for everything from nozzle blobs to zits, from stringing to warping.

Machine Learning is being used in a variety of applications?