Luminous, Self-Powered 3D Skins for Underwater Communication

A team of researchers at the National University of Singapore has successfully 3D printed an elastic “photonic skin” capable of generating light without the need for batteries or cables. Thanks to an auxetic design, meaning it expands when stretched rather than contracting, this technology promises to improve communication and safety in underwater environments, from recreational diving to robotic exploration in deep waters.

Underwater exploration remains a challenge. Low visibility, salinity and extreme temperatures damage conventional electronic devices. Although LEDs and optical fibers are used in some equipment, their dependence on external power sources and limited flexibility reduces their usefulness in dynamic conditions. The new approach combines mechanoluminescence, the ability of certain materials to emit light when stretched or pressed, with 3D printing of auxetic structures. The result is a material that glows when moved and adapts to curved surfaces such as gloves, air tanks or even soft robots.

Auxetic structures adapt to curved surfaces, are elastic, shiny and have exceptional durability even in adverse conditions, enabling reliable exploration in deep waters.

3D Printing and Auxetic Materials

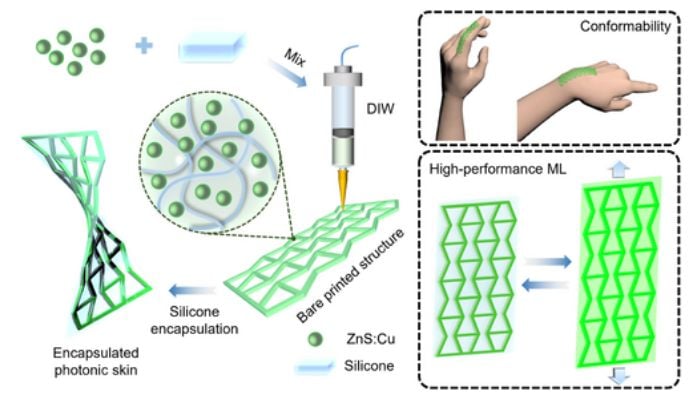

The team printed ZnS (zinc sulfide) cellular structures in a silicone matrix. This compound is stable, biocompatible, and safe for marine environments. In this way, the auxetic design improves the material’s adaptability to complex geometries. An outer layer of silicone distributes stress more evenly, ensuring uniform luminosity even under repeated stretching. According to the experiments, the photonic skin maintained its performance after more than 10,000 cycles of use, demonstrating remarkable durability for demanding applications.

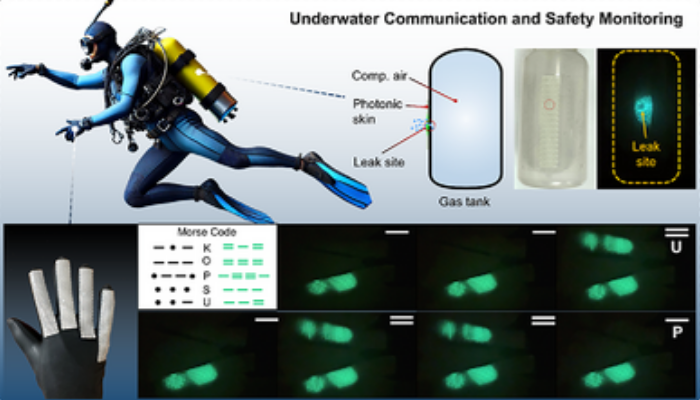

To demonstrate its potential, the researchers integrated the material into different objects. One example is a luminous glove for transmitting Morse code signals underwater. Another is a robotic fish that glows when in motion, useful for testing in underwater robotics. In addition, they applied it to a gas tank, where the photonic skin detected and communicated leaks. These tests show that the material is viable as a visual communication system or as a system for real-time safety monitoring.

Representation of the photonic skin manufacturing process. The skin adapts and shines when deformed.

The research team pointed out that 3D printing allows them to create devices with complex geometries that were previously impossible to manufacture. They claimed that in this case, it is the key to generating, distributing and maintaining stable light, even under extreme conditions. The next challenge will be to improve resistance in humid environments and expand the scale of production. If successful, this technology could become a standard for diving equipment, underwater robots and wireless communication systems, all powered by additive manufacturing. Find more information about the study here.

What do you think of this development? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Jason Edwards / Getty Images