LulzBot unveils its first open-source bioprinter

Last June, Aleph Objects announced its collaboration with FluidForm, the two companies were setting out to create a new bioprinting hardware with the long-term goal of creating real functional tissues. Aleph Objects, the manufacturer of LulzBot 3D printers decided to partner with FluidForm because of its innovative technique in bioprinting. FluidForm’s proprietary technology is called FRESH (Freeform Reversible Embedding of Suspended Hydrogels) and enables the creation of bioinks and other soft materials. At the beginning of August, researchers from Carnegie Mellon University were coming one step closer to the creation of functional 3D printed organs by using this exact technology from FluidForm.

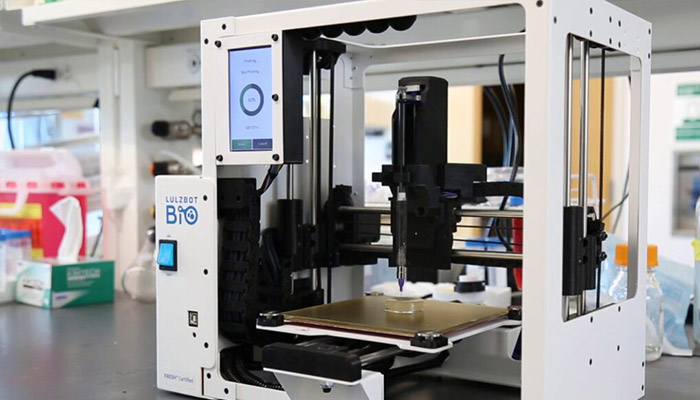

The new bioprinting hardware from LulzBot and FluidForm is finally available for pre-order. The open-source Fluid Deposition Fabrication (FDF) bioprinter is called LulzBot Bio, and should start being shipped out in November. It will enable bioprinting of unmodified collagen, bioinks and other soft materials.

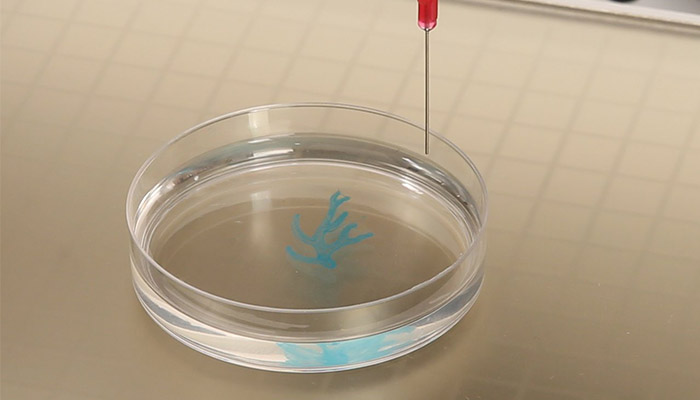

A 3D printed artery structure on the new LulzBot Bio, optimized for FRESH printing | Credits: LulzBot

During the summer, researchers at Carnegie Mellon explained the benefits of the FRESH process after successfully bioprinting heart valves from unmodified collagen. In fact, they were able to create complex scaffolding with unmodified collagen right from the start of the printing process by using a temporary support gel. The gel acted as a printing medium as it allowed to maintain the extruded biomaterials in place, minimising the risk of deformation. This gel was then heated to easily remove the bioprinted part.

Unmodified collagen is usually very difficult to work with due to its fluid nature, therefore this technique can allow new applications in the bioprinting field. The aim of Aleph Objects is to expand beyond unmodified collagen to include other soft materials such as alginate, fibrin, and hyaluronic acid. Grant Flaharty, CEO and President of Aleph Objects commented on the open-source property of the LuzBot Bio: “For researchers, you don’t know what materials or processes you’ll be using in six months, let alone one year from now, so you need hardware that can be adjusted quickly and easily, without proprietary restrictions.”

The Lulzbot Bio

According to the company, LulzBot Bio will satisfy the needs of many sectors, including biotechnology, pharmaceuticals, cosmetics, medical devices, and life sciences. It could be used for producing bioprinted tissue for preclinical testing or to study diseases.

What do you think of this new open-source bioprinting hardware? Let us know what you think in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!