Fast or Slow? LLNL Studies How Laser Speed Controls Microstructure in High-Entropy Alloys

Imagine being able to tune the properties of metal, making it either resistant to force but brittle, like a ceramic tile, or yielding yet bendable, like a paperclip. Achieving this level of control requires precise manipulation of a material’s internal structure as it forms. Scientists have now demonstrated a way to do just that by tailoring high-entropy alloys through additive manufacturing. Researchers from Lawrence Livermore National Laboratory (LLNL) in the United States, along with collaborators, investigated how processing conditions can be used to customize next-generation high-entropy alloys (HEAs).

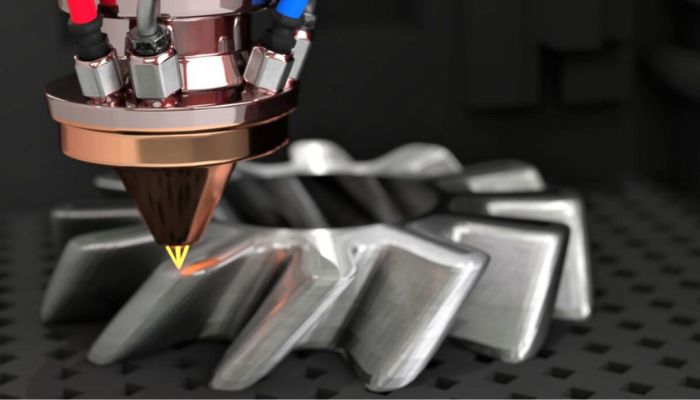

Specifically, the study aimed to understand how solidification rate influences microstructure evolution and phase transformation pathways in laser additively manufactured HEAs (in this case, AlCrFe₂Ni₂ eutectic HEAs). They controlled the solidification rate by adjusting laser scanning speeds, which affected how the metal cooled and, in turn, its internal structure. The team combined thermodynamic modeling and molecular dynamics to simulate 3D printing these HEAs.

The researchers leveraged rapid cooling during the AM process to dictate how the atoms settle as the metal solidifies. (Photo: Needpix.com)

The research, published in Advanced Materials, demonstrated that when the laser moves slowly, the molten metal cools at a low rate. This gives atoms in the liquid sufficient time to move through diffusion and naturally separate into distinct components, or “phases.” By contrast, when the laser scan speed is increased, the metal cools extremely rapidly. This rapid cooling suppresses diffusion, meaning atoms do not have enough time to move or separate. As a result, the material effectively “freezes” as a single, uniform solid phase, rather than separating into the complex mixture it would typically form.

“By increasing the laser speed, the cooling rate increases,” explained Deputy Group Lead Thomas Voisin, “and as the material cools down faster, it has less time to rearrange to a low energy configuration. This freezes the material in a non-equilibrium state, which can be used to tune atomic structures and resulting mechanical properties.”

With this knowledge, the scientists could harness the versatility of high-entropy alloys, tailoring their properties to meet specific needs. It’s like unlocking multiple materials within one by just adjusting the laser speed: with the AlCrFe₂Ni₂ eutectic HEA, the researchers were able to create an entire spectrum of properties. Ultimately, this study shows that manufacturing techniques can be precisely tuned to customize the mechanical strength and durability of advanced metal components.

What Could This Mean for AM?

Researchers have long recognized that additive manufacturing’s fast cooling rates lead to unique microstructures in HEAs, often resulting in finer grains, altered phase distributions, and enhanced mechanical properties. The knowledge unlocked by LLNL sits within an active and expanding research area where scientists are systematically investigating how laser AM processing parameters can be used to tune microstructures and thus customize mechanical behavior in high-entropy and other advanced alloys.

Could this approach mean that additive manufacturing is not just a production tool, but a platform for discoveries? Rather than going through multiple trial recipes, additive manufacturing could be used for engineering materials with properties programmed into them. “We are now at a place where we can effectively design new materials that take full advantage of the additive manufacturing features like the very rapid cooling rate,” Voisin said. If you want to learn more about the project, read the study HERE.

What do you think of LLNL’s metal 3D printing project? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*Cover Image: Artist rendering of LLNL’s new additively manufactured high-entropy alloys. (Graphic: Daniel Herchek/LLNL)