Little You Talks Using Additive Manufacturing to Create Customizable Toys

We have seen time and again that the additive manufacturing market is rapidly industrializing. However, industrial applications are not the only way that we can use 3D printing. This was recognized by Canadian company, Little You, who allow children to make fully customizable, 3D printed toys right through their website. Using a variety of machines designed for material jetting, which is often used for artistic projects thanks to its beautiful final pieces and ability to mix colors and materials, the Little You allows every child to take advantage of the benefits of 3D printing to unleash their own creativity. We sat down with the founder, Christina Guo, to find out more.

3DN: Can you introduce yourself and Little You?

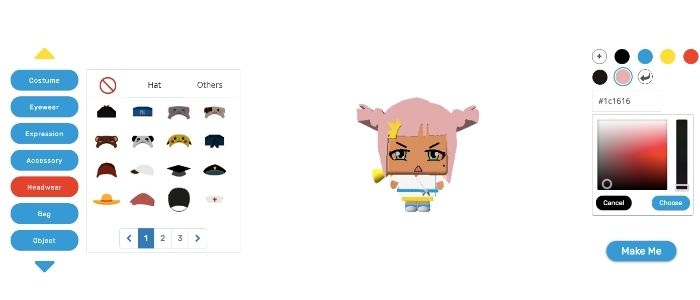

Little You is a digital platform that gives children from 6 to 18 years of age the chance to design, personalize, and create custom characters using the latest web and 3D printing technology. By allowing children to design and customize 3D characters, children can create a 3D character and customize every aspect of their appearance and identity. Users can select and add different costumes to design their 3D figures, and they also have the freedom to change color, size, and position for various add-on accessories. Little You brings the 3D model to life with 3D printing. The 3D printers are at the company’s facility in Ontario and then delivered to clients anywhere in the world. The company ensures that its products are of the highest quality by working with industrial printers. The industrial printers print quality products to company’s customers. However, the company’s website also provides clients an option on the website to purchase and download 3D models, which they can print at home.

Little You is a digital platform that gives children from 6 to 18 years of age the chance to design, personalize, and create custom characters using the latest web and 3D printing technology. By allowing children to design and customize 3D characters, children can create a 3D character and customize every aspect of their appearance and identity. Users can select and add different costumes to design their 3D figures, and they also have the freedom to change color, size, and position for various add-on accessories. Little You brings the 3D model to life with 3D printing. The 3D printers are at the company’s facility in Ontario and then delivered to clients anywhere in the world. The company ensures that its products are of the highest quality by working with industrial printers. The industrial printers print quality products to company’s customers. However, the company’s website also provides clients an option on the website to purchase and download 3D models, which they can print at home.

It was idealized and developed by me, Christina Guo, as a unique option for kids to boost their eagerness to explore and create something exclusive, offering a customizable experience, with the development and design of their avatar, from modeling and coloring to physically accessorize the characters. The idea came up while I was studying at OCAD University. As an artist and a believer of the importance of creativity and seeing the world through the eyes of a child, I strive to provide countless opportunities for children to acquire social skills while bringing families closer together. To make our toys, we work with a few different offerings including ProJet CDP 660 (full color sandstone), Mimaki Color printer and Rize3D

3DN: How does your customization software/app manage the interaction between customer inputs, and machine & material?

The customization software we use at Little You allows kids to customize the design of 3D characters like the entire look, color, size and personality along with size, position or color of accessories as per their liking. Customers have to choose the type of material for the 3D characters before making the final payment. Options of printable material are:

- Full-color sandstone, made out of Gypsum looks like plaster

- Full-color glass fiber or an industrial thermoplastic

- Full-color acrylic resins that create 3D characters using UV curable inkjet technology.

An example of how someone could customize a toy (photo credits: Little You)

After the kid submits the final design of his/her character on the website, the layering method also known as additive manufacturing is used for manufacturing 3D models from 3D printers. The 3D figures are printed on the selected material. The final result or final character will be a mirror image of the design submitted on the website. The final product is then delivered to customers across the world.

3DN: What are the advantages of using additive manufacturing for toys? Are there any challenges?

There are many advantages to using additive manufacturing in the creation of toys. For example, the cost of equipment has been drastically reduced with the use of additive manufacturing in toys, which results in an increase in profitability; toy can be easily modified and designs can be easily changed also multiple designs can be produced at the same time; the process does not require different molds for different designs; the process is faster as compared to the traditional toy-making process; material used for 3D printing is lightweight and strong; there is no need to maintain inventory if not producing in bulk; these toys use less material, which results in the use of less energy and less wastage during manufacturing. It’s more eco-friendly than the traditional method; demand for customized toys is increasing day by day; finally making changes in design is easy less time-consuming, the aritst just needs to make changes in original design with minimal cost.

That being said, there are still challenges of using the technology for toys. One of the biggest of course is that the production cost of 3D printed toys are still relatively high compare to mass produced toys. But also, general public are not aware of the potential of 3D printing.

Photo Credits: Little You

3DN: What are some of Little You’s future projects?

Little You will continue to adopt the most advanced 3D printing technology and use industrial printers to deliver products. If one-day desktop printers become popular, and everyone has a 3D printer at home, Little You will also be able to leverage, since we provide the option for people to download and print at home. We will always look to adapt to the latest advancements that are available in the 3D printing industry so as to always remain ahead of the curve.

Little You will introduce new features in the upcoming future, such as adding words and texture image to decorate their figure and provide more advanced customization experience for the customers. Moreover, Little You will consider develop Little Pet, Little Home, Little Sculpture to broader our product line. We will also consider working with licensed brand for limited edition.

3DN: Any last words for our readers?

Our goal is to accelerate the 3D printing industry and offer 3D printed green products made of recyclable materials. As consumerism turns away from mass-produced goods, and moves towards customized, and personalized goods, we will be at the forefront of this movement, through the custom products we offer. Feel free to customize a mini you on our website HERE.

Would you be interested in getting a customized, 3D printed toy? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Little You