Lino3D facilitates the integration of 3D printing technologies for industry professionals

Expert in 2D printing for more than 30 years, the Greek Lino Group recently opened an entity fully dedicated to additive manufacturing. Named Lino3D, this unit aims to support manufacturers in their manufacturing process, to help them choose the right process, the right materials and acquire the necessary skills to understand the stakes and functioning of 3D printing technologies. For example, the company masters Material Jetting processes, in particular the one developed by XJet. According to the company, this is the most efficient method available on the market, combining precision and speed, material availability and fine detail. Lino3D is able to support companies interested in polymers, metals but also ceramics. We met this Greek player who intends to put its expertise in manufacturing technologies at the service of professionals and industrialists worldwide.

3DN: Can you introduce yourself and your relationship with additive manufacturing?

Lino Group is a group of companies founded by engineering specialists and system integrators in 1997. We specialize in 2D and 3D digital printing technologies and software development for the communication industries. Our printing expertise dates back nearly 35 years, giving us enough experience to carry out our mission. Over the years, and of course throughout the expansion and development of 2D technologies, we have seen a rapid growth in 3D technologies, and we recognize that it was both our own instincts and the pulse of the global industry that led us to move into additive manufacturing in 2016. At that time, 3D printing was an established technology, but the newer direction of Material Jetting technology offers the opportunity to move from functional prototyping to full production. Our expertise in 2D printing in inkjet technology gives Lino3D a definite advantage and we fully intend to exploit it for further development.

- Christos Anastasiou

- Lefteris Havouzis

3DN: Why did the Lino Group decide to create a business dedicated to 3D printing?

As engineers, know-how is the most important factor in acquiring the necessary knowledge and of course in facing new challenges. On the 3D printing market, this know-how is unique. By creating a laboratory dedicated to 3D printing, we are able to push our limits, learn more and share the results directly with our customers. When you are able to demonstrate the procedures and processes of 3D printing in situ, I firmly believe that you succeed in creating the interest and, most of the time, the confidence to go further.

3DN: What is Lino3D’s main mission today?

Lino3D has already laid down the basic knowledge of 3D printing and is moving forward to develop new applications and new materials. We really want to introduce this pioneering technology into new and conventional industries and show the world that additive manufacturing is there to facilitate our operations. It’s quite fascinating to think that it is now easy to print what you need instead of anticipating a solution, which is often complicated.

3DN: Can you tell us more about the 3D printing technologies Lino3D masters today?

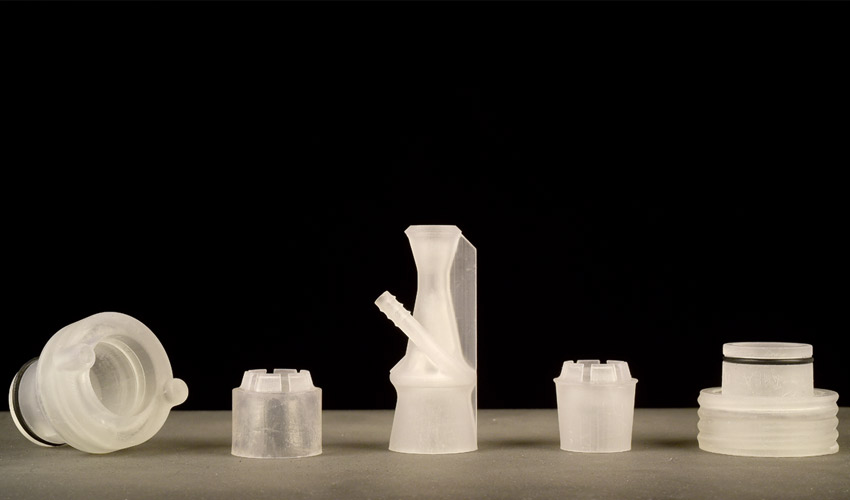

Lino3D is equipped with a variety of additive manufacturing technologies and materials. We are currently mastering SLA, DLP, FDM and Binder Jetting technologies. However, the added value of our laboratory is the fact that we supply a wide variety of materials for the above-mentioned technologies, from plastics (resins and filaments), to metals (stainless steels and alloys), to ceramics (zirconia and alumina).

3DN: Which one do you believe has the greatest potential?

From our point of view, the technology that currently has the greatest added value is Material Jetting technology. This is a process that is based on the technology used in 3D printing, which gives us a valuable advantage due to our experience. In additive manufacturing, it is a method with a speed that can certainly meet the challenges of high-volume production. Its precision provides the best results for the end user with little post-processing and in a fraction of the time. Today, Lino3D is equipped with XJet’s Nanoparticle Jetting system and is expected to receive its Desktop Metal Binder Jetting system in the fourth quarter of 2020.

3DN: Who are your customers today? Which sectors are you targeting?

Lino3D has been on the 3D market since September 2016, and throughout these years we have managed to acquire customers from a wide range of industries. In the beginning, we specialised in dental, orthodontic and medical applications and materials, as the majority of our customers were in the medical sector. However, in the last two years we have broadened our spectrum to include industrial and automotive applications as well as jewelry. We closely follow developments in 3D printing technologies because the market sectors they address are endless.

3DN: How do you see the additive manufacturing market evolving in the next few years?

Since the beginnings of 3D printing technology, we have witnessed its rapid development and constant evolution. The various additive manufacturing processes have succeeded in creating a wave of brainstorming to constantly bring improvements and ways to simplify procedures. We believe Material Jetting technology is the most revolutionary method. It is a well-known technology developed by the 2D industry and has been modified for the needs of the 3D printing industry, offering the best results in terms of speed, precision and variety of materials. It can be applied to metals and ceramics as well as plastics, giving industries the possibility to produce functional parts at an extremely low cost. In the near future, we are more than confident that this technology will replace, to a large extent, conventional manufacturing methods in sectors such as aerospace, automotive and, of course, MIM.

3DN: A final word to our readers?

We are available and ready to support any customer in any market segment to explore with them other applications and reach the full potential of the technology. You can find more information on our official website HERE.

What do you think of Lino3D? Let us know in a comment below or on our Facebook and Twitter pages! You can also check out our Youtube channel for videos on AM!

Hello. Excuse me, perhaps for an incorrect question, since I am not an expert in this area. Is it possible to make products using 3D-printing from durable and non-combustible materials?