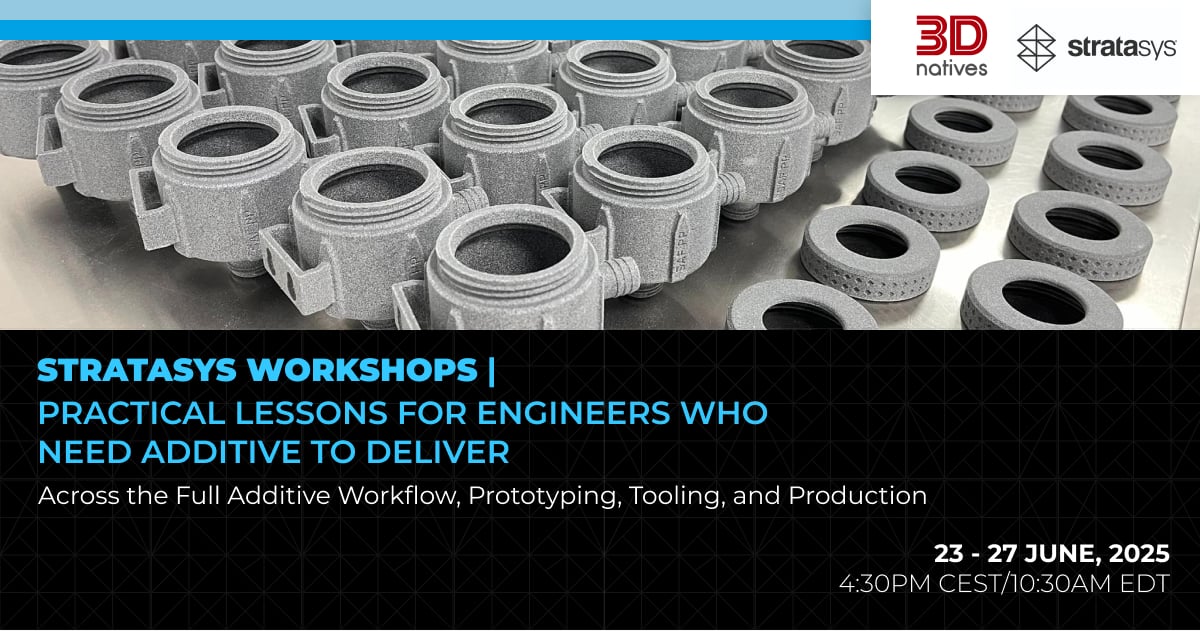

Workshops | Practical Lessons for Engineers Who Need Additive to Deliver

From June 23rd to 27th, 2025, the 3Dnatives team, in collaboration with Stratasys, invites you to join the free “Practical Lessons for Engineers Who Need Additive to Deliver” workshop series. These five expert-led sessions are designed to support engineers and manufacturers throughout the entire additive workflow: prototyping, tooling, and production. Each day from 16:30 CEST / 10:30 EDT (30 minutes per session), a different expert will guide you through real-world insights into additive technologies.

Attend all sessions to receive a Certificate of Attendance, recognizing your participation in cutting-edge additive manufacturing strategies. Mark your calendar—you won’t want to miss it!

Workshop #1 – Stop Compromising on Prototypes: 3D Print Across All Product Development Stages

Why choose between function and aesthetics? Engineers require performance, designers need realism. Learn how PolyJet, FDM, and SLA let you achieve both.

- Functional vs. aesthetic: why not both?

- Technologies for high-fidelity prototypes

- Impress clients, reveal design flaws earlier

Workshop #2 – Smarter Tooling with 3D Printing: What Works, What Doesn’t, and How to Start

Join Dave Hayden, a Mechanical and Global Application Engineer with 11 years of experience in additive manufacturing (AM), as he walks you through the do’s and don’ts of 3D printed tooling—and how to spot opportunities in your own factory.

- Tight-tolerance tooling with less weight

- Faster print times without sacrificing quality

- Spot tooling opportunities in your operations

Workshop #3 – Unlocking Production Potential: Materials, Systems, and Certification Advances

Discover how FDM is evolving to support production-grade parts. Explore how new materials, open systems, and certifications unlock new possibilities.

- Produce with certified materials

- Expand capabilities with open systems

- Meet industry-specific production standards

Workshop #4 – Specialty Materials for the Most Demanding Applications

Discover engineered materials for high-demand applications. From ESD to FST, UV resistance to elastomers – see what’s enabling next-level parts.

- UV, moisture & chemical-resistant materials

- ESD-safe, FST-rated, and flexible options

- Applications: molds, connectors, machine parts

Workshop #5 – Turning Waste into Parts and Profit

Waste PA12 is a challenge – but also an opportunity. Learn how SAF ReLife enables zero-cost part production from your own SLS/MJF powder waste.

- Recycle PA12 powder from your own operations

- Stratasys H350 open workflow customization

- Produce usable parts with no material cost