Lines Manufacturing Is Combining Large Format and High Speed in Its Industrial 3D Printer

Founded in 2019, French start-up Lines Manufacturing intends to make its mark on the large-format additive manufacturing market with its Lines SONIC solution. The special feature of this FGF machine is the printing speed it can achieve, even on large volumes, without sacrificing precision. In this way, the manufacturer aims to meet the challenges of plastics and composites manufacturers by offering a flexible, competitive solution capable of mass-producing up to several thousand large parts per year per machine. This new “series” approach goes beyond the traditional use of large-format additive manufacturing, which is generally confined to prototyping, enabling the benefits of 3D printing to be deployed on a larger scale. The first machine deliveries are scheduled to begin in 2025, following several years of industrial trials, including those carried out for one of the leaders in connected mobility, OPmobility (formerly Plastic Omnium) as early as 2022.

When it comes to large-format 3D printing, the trade-off between part size and quality is often a major challenge. The larger the part, the longer the printing time. Reducing this time often means sacrificing the quality of the final part by depositing thick, coarse layers. What’s more, mastering large-format additive manufacturing requires specific knowledge, as machine set-up is crucial to avoid defects that can be costly, both in terms of money and time. This is where Lines Manufacturing can provide an industrial solution and proven know-how to meet these challenges.

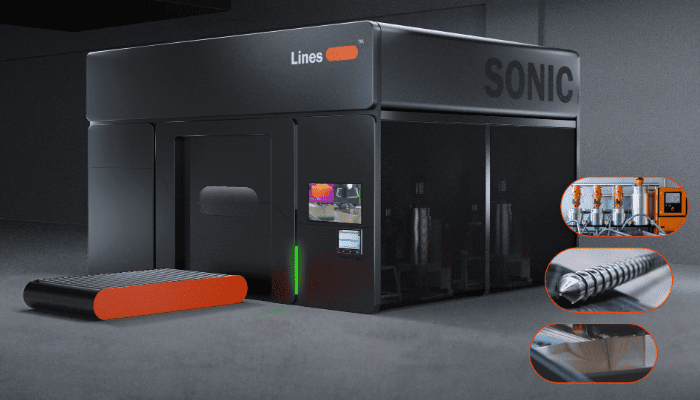

The Lines SONIC machine

Large-Format Additive Manufacturing Without Compromise

According to Lines, its SONIC machine is 10 to 100 times faster than current solutions, while offering a standard print volume of 3,000 x 2,500 x 2,500 mm. In fact, printing speed can reach 2,000 mm per second (2m/s), with material deposition of up to 80 kg per hour, all while maintaining fine layer heights (from 0.4mm). These specifications are quite unique when compared with other large-scale additive manufacturing systems, and reflect Lines’ ambition to offer a genuine production solution capable of high production rates. Lines SONIC uses a polymer pellet extrusion process specifically developed and patented by the company.

Niels Pernoux, co-founder and president, explains: “We have developed an industrialized high-speed additive manufacturing solution that offers a real opportunity to mass-produce finished and semi-finished parts from start to finish, with advanced integration into tracking tools. This approach enables us to meet the requirements of the most advanced sectors of industry.”

In terms of applications for such a machine, its capacity for medium-volume production is ideal for the marine, aeronautical and mobility sectors, whether rail or mechanical engineering. Meanwhile, its large format and high speed make it possible to bridge a technological gap between unit and mass production processes, enabling high-volume production without the need for tooling. One of the first users of the Lines process is OPmobility, a major player in sustainable mobility.

Construction machine hood made on the Lines SONIC machine – part dimensions 1600 x 1300 x 850 mm

Mastering Shock Absorption With Additive Manufacturing

The company worked with the French manufacturer on the Smart Polymer Bumper project. The aim was to design impact and energy absorption parts using an automotive-grade polypropylene material already certified by the OEM, thus facilitating material characterization work. After a study and simulation phase, absorbers for the front end of vehicles were produced using 3D printing on a Lines SONIC machine.

The application involved understanding and controlling the behavior of the parts to fulfill the energy absorption function. Relying on additive manufacturing, the research and innovation team successfully developed and experimentally tested different lattice structures that were more efficient than the foam structures currently used. Lines SONIC therefore enables the mass production of certain functional and technical automotive parts.

Lines Manufacturing, a fast-growing industrial startup, is launching Lines SONIC at Formnext 2024 following the public presentation of its machine. Looking to the future, the company continues to structure itself around a strong vision: to develop the production solutions of tomorrow. Backed by several major French industrial groups, these development projects include diversification of the machine range and the development of an assembly site in the Grand Est region.

To find out more about the machine’s specific features and detailed examples of industrial applications, visit Lines at Formnext (stand E21, Hall 12.0). You can also find more information HERE.

What do you think of this solution from Lines Manufacturing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Lines Manufacturing