LEAP 71 Combines AI and 3D Printing to Produce Futuristic Rocket Engines

With the spirit of the space race living on in the private sector’s innovative drive towards the stars, engineering company LEAP 71 and spacecraft manufacturer The Exploration Company recently announced a partnership to accelerate space exploration. The two companies want to develop more efficient calculation and manufacturing models for designing space vehicles. In order to achieve this, they are using a combination of artificial intelligence and additive manufacturing. LEAP 71 has developed a computational engineering model that enables it to design complex, high-performance rocket engines that can then be 3D printed. By combining AI and additive manufacturing, the two partners hope to not only reduce production costs, but above all to accelerate innovation in the aerospace sector.

Additive manufacturing, particularly with metal, already has a strong history within aerospace and space exploration with designing and manufacturing finished parts for rockets and satellites. Therefore, the objective for LEAP 71 and The Exploration Company is clear: to build on these successes in the industry and reduce component weight and manufacturing time in order to offer a more viable business model and higher-performance craft. While some industry players are concentrating on developing specialized machines capable of printing large parts, others are focusing on creating computational models to offer greater complexity to parts that can be 3D printed today, such as rocket engines. This is where Dubai-based LEAP 71 is headed.

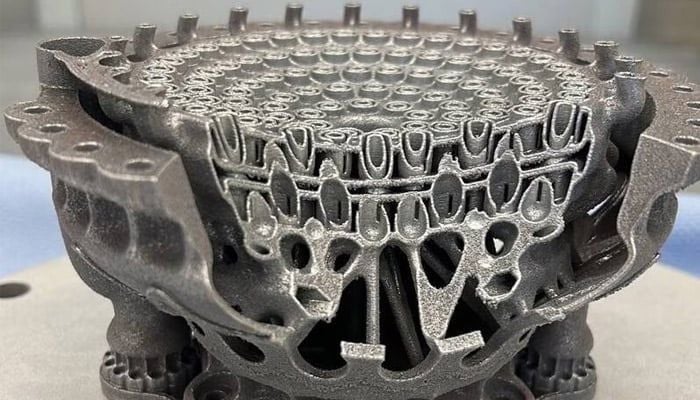

Cross-section of a LEAP 71 engine piece

The team at LEAP 71 has joined forces with The Exploration Company, the Franco-German company behind the Nyx: a modular, reusable orbital space vehicle designed to make space exploration more affordable. The Exploration Company co-founder and CEO Hélène Huby explains their decision to work in tandem with LEAP 71, “One of the challenges for reducing the cost of space exploration is the conventional approach to engineering. Complex parts like rocket engines are hard to design, and each iteration can sometimes take a significant amount of manual rework with traditional CAD-based tools. Using computational models, we want to engineer faster, so that we can print and test faster – hence accelerating the improvement and validation of our engines.”

LEAP 71 will use its computational model to design different rocket engines, which will be 3D printed for testing and eventual validation. Additive manufacturing offers the perfect way of offering different versions of a single product. Founder and managing director of LEAP 71, Josefine Lissner, sums it up, “We are excited to put our Computational Engineering Model to the test and get real-world feedback, to fine-tune it to the point, where we have a robust foundation. I expect a tipping point in the space industry when our model successfully starts producing operational engines across a wide range of parameters. As each new test feeds back into the model, the resulting objects will improve exponentially. This is a key building block on our path to a space-faring society.” While we await further news and results regarding the first 3D-printed parts from these two partners, you can find out more about LEAP 71 from their own site HERE.

What do you think about LEAP 71 and The Exploration Company’s collaboration? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All photo credits: LEAP 71