Layer One: Makers of the Hybrid FDM & SLA 3D Printer

Our startup of the month for December is Layer One. Layer One is a company that created a hybrid 3D printer that combines FDM and SLA technologies. We have already discussed the main types of FDM 3D printer on our site. This enables it to 3D print in a variety of materials. We were so impressed that their Atom 3D printer could do this that we had to find out more. Therefore, we sat down with Layer One to get more of an insight into this new 3D printer.

3DN: Can you introduce yourself and your company? How did the idea of a hybrid printer come up?

I’m Mike Galvez and I head up Global Marketing at Layer One. It’s always been our goal to make Atom a complete desktop digital printer, so we couldn’t just stop at FDM. SLA technology lets you break through many of the barriers of FDM, like being able to print minute details. The only thing that prevented us from implementing the idea sooner was the size and shape of SLA units up until very recently. Advances in LCD technology have really moved the ball forward which lets us pack a powerful apparatus into a compact space that works with the Atom’s modular system. So the goal has always been there, but the latest technology has only just made it possible to achieve.

Interchangeable parts in Layer One’s Atom 2.5 printer.

3DN: How do you switch the technology of the printer?

Thanks to the Atom’s MagSwap system, which is getting a big upgrade in holding power for Atom 3, switching between the two modes is done with a quick swap of the end effector. The FDM Print Module is swapped for the SLA Build Module and the resin tank is affixed to the base of the machine. The firmware basically takes care of the rest.

3DN: What materials can you use on the Atom 3? What is the expected price?

When Atom was still in its infancy, we took pride in how easily it printed PLA. People often take that for granted nowadays, but ABS used to be the only thing people printed with because it was the only plastic that wouldn’t get stuck in the nozzle. It was tough to engineer a nozzle with a tiny melt zone and a super sharp heat break to prevent PLA from clogging, but we did it before almost anyone else because frankly, we were tired of ABS. It stinks, it has poor layer adhesion, and it’s not exactly green or sustainable.

Now we know that people want more options, even on the desktop where PLA is probably the safest plastic you can use, so the new engineering challenge is to find an easy way to print as many materials as possible. That becomes even more challenging when you’re combining multiple materials in one print. The Atom 3 will be able to print almost every material out there, and be able to combine multiple materials while printing faster than ever before. While you’ll have to wait for the official launch for the price, I can say that even casual hobbyists will find it to be an excellent value for the money given all the functionality it will offer.

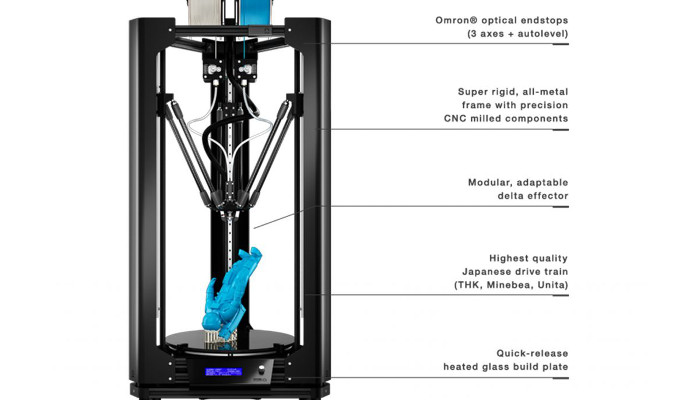

Specifications and parts of the printer.

3DN: Who are you targeting with your new printer?

If you are taking your designs from digital to physical on a daily basis, then the Atom is for you. To be more clear, Atoms are sophisticated machines for sophisticated users. Our goal is to give those advanced users as much power and functionality as possible in the most elegant package. We strive to deliver a machine that the professional can take full advantage of, and also one that the student can confidently learn with.

3DN: What are your future developments?

Whatever tool in the realm of digital fabrication you can imagine, we are trying to put it into an Atom. Atom 3 will start with a handful of tools, and we will be working to develop more.

3DN: Any last words for our readers?

Twenty years from now the phrase “3D printer” will have largely been forgotten. It will probably be replaced by something shorter and easier to say. Maybe a four letter word. Possibly starting with “A.”

Did you find this interview interesting? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!